Design and Development of a Portable Sisal Decorticator

Research Article

Design and Development of a Portable Sisal Decorticator

Tanveer Ahmad1, Hafiz Sultan Mahmood1*, Zulfiqar Ali1, Muhammad Azeem Khan2 and Shahid Zia3

1Agricultural and Biological Engineering Institute, National Agricultural Research Centre, Park Road, PO Box 45500, Islamabad, Pakistan; 2Social Sciences Research Institute, National Agricultural Research Centre, Park Road, PO Box 45500, Islamabad, Pakistan; 3Lok Sanjh Foundation, Mangla Road, Sector G-9/3, Islamabad, Pakistan.

Abstract | The demand of natural fibres is increasing in the world for industrial uses to make high value products. An enormous potential of sisal fibre is present in Pakistan for making ropes, twines, paper, carpets, cloth and handicrafts, which has not been exploited so far. The aim of this study was to design and develop a small-scale portable sisal decorticator for extracting fibre from sisal leaves. A prototype of sisal decorticator was designed and fabricated at Agricultural and Biological Engineering Institute, National Agricultural Research Centre, Islamabad. The prototype machine was tested for fibre extraction. Results indicated that sisal fibre production capacity of this machine was 15.94 kg h-1 (dry fibre). Average yield of dry sisal fibre was 3.2% of green leaf weight and average fibre length was 1348.9 mm per leaf. Average power required to decorticate sisal leaves was 3.1 kW. Operating cost of sisal decorticator together with a combing machine was Rs. 507.9 h-1. The break-even point or payback period of this technology was 233 h. Sisal fibre needs to be washed, dried and brushed after decortication process for getting good quality fibre to make domestic products. This technology has a great potential and needs to be commercialised in sisal growing areas of the country.

Received | June 03, 2016; Accepted | Jul 24, 2017; Published |September 18, 2017

*Correspondence | Hafiz Sultan Mahmood, National Agricultural Research Centre, Islamabad, Pakistan; Email: [email protected]

Citation | Ahmad, T., H.S. Mahmood, Z. Ali, M.A. Khan and S. Zia. 2017. Design and development of a portable sisal decorticator. Pakistan Journal of Agricultural Research, 30(3): 209-217.

DOI | http://dx.doi.org/10.17582/journal.pjar/2017.30.3.209.217

Keywords | Portable sisal decorticator, Design of raspador, Fibre extraction, Economic analysis, Break-even point, Wild sisal plants

Introduction

Many plants produce fibre from their fruits, seeds, stems and leaves, such as coir, cotton, kapok, hemp, ramie, flax, kenaf, jute, nettle, manila, abaca, bamboo and sisal (Akin et al., 2000; Smole et al., 2013). Sisal (Agave sisalana) is a fibrous plant, which is originated from Mexico (Chand and Rohatgi, 1994), but widely cultivated and naturalised in many other countries, such as Brazil, China, Kenya, Tanzania, Madagascar and Mozambique (FAO, 2013). The Sisal plant has a shallow root system that goes about 0.6 m deep and has 7-10 years life (Mwaikambo, 2006). Sisal is cut first time after 2-3 years and is subsequently cut after every 6-12 months. Sisal can be grown in wasteland, dryland and in saline soils and it can withstand severe drought conditions (Shamte, 2000). In Pakistan, sisal plants are found as a wild species, which is spread over a wide range of geographical areas including deserts in the Punjab and coastal belts of Sindh and Balochistan provinces. The use of sisal plant was also not known in the country except burning it as fire wood.

Sisal fibre is mostly used in cordage industry due to its great strength, better spinning characteristics and resistance to the action of saline water (Lock, 1969; Naik et al., 2013b). Sisal fibre is considered a renewable resource with several environmental advantages over glass fibres, which is mostly used to make baler twines in agriculture (Leão et al., 2006). Other important traditional uses include making carpets, rugs, sacks, yarns, general and marine ropes and other domestic products (Müssig, 2010).

Sisal leaves are harvested manually using a sickle. A mature leaf attains a length of about 0.6 to 2.0 m (Brenters, 2000; Smole et al., 2013). Cut leaves are decorticated the same day or within 48 hours to prevent their deterioration, if exposed to sun. In the past, the fibre was extracted manually by scraping away the pulpy matter with a blunt knife. Sometimes, leaves were cut longitudinally into thin ribbons and immersed in water till the pith matter was separated from the fibre (Naik et al., 2013b). After retting, the fibre was washed and dried in the sun. Sometimes sisal leaves were boiled in water and beaten to remove the pithy matter from fibre, which was then washed and dried (Naik et al., 2013b; Srinivasakumar et al., 3013).

Mechanical decorticating machines have also been developed for extracting sisal fibre (Brenters, 2000; Kanogu et al., 2011; Snyder et al., 2006). Sisal leaves are scrapped and beaten by a rotating cylinder (raspador) having blunt blades on its periphery and the flesh material is decorticated whereas the fibre remains. The decorticated fibre is then washed with water to remove crushed matter before sun drying.

In Pakistan, sisal fibre has great commercial benefits, such as for making ropes, mats, carpets, handbags, etc. However, hand processing of sisal leaves is a tedious, laborious and slow exercise resulting in low productivity and low quality of the fibre. Moreover, the acidic sap released during manual decortication causes skin irritation and discomfort (Naik et al., 2013b). To address this issue, a small-scale sisal decorticating technology is needed in the country. The objective of this study was to design, develop and evaluate the performance of a small-scale portable sisal-decorticating machine.

Materials and Methods

Design and fabrication of a sisal decorticator

A portable sisal decorticator was designed employing AutoCAD software (Version 2007, Autodesk, Inc.) and fabricated at Agricultural and Biological Engineering Institute (ABEI), National Agricultural Research Centre (NARC), Islamabad. The main components included prime mover (diesel engine), raspador (cylinder) with blunt blades, breastplate (cutting plate), waste chute, trolley wheels with axle, a hook for hitching and the main frame of the machine. All fabrication parts were made of mild steel (MS) because it is cheap, durable and readily available everywhere. Standard components, such as bearings, diesel engine and tyres were purchased from the market. The detail of material list is shown in Table 1. The assembly drawing together with part detail of the portable sisal decorticator is shown in Figure 1.

The diameter of raspador with L-shaped blunt beater blades was 530 mm. The dimensions of L-shaped blunt blades were 38 mm × 38 mm × 6 mm. The width of raspador was 470 mm. The raspador was suspended by a 38 mm shaft with two deep-grooved ball bearings (P-207). Two double section B-type v-grooved pulleys were provided to drive the raspador. An adjustable

Table 1: Material list and specifications of different components of sisal decorticator

| Name of machine component | Material with dimensions/specifications |

| Main frame | MS channel (105 mm × 50 mm × 6 mm) |

| Raspador |

MS pipe (outer φ = 454 mm , t = 6 mm) |

| Beater or blades | MS angle iron (38 mm × 38 mm × 5 mm) |

| Raspador shaft |

MS polish bar (φ 38 mm) |

| Breastplate | MS plate (t = 12.5 mm) |

| Casing and waste chute | MS sheet (t = 2 mm) |

| Wheel axle |

MS pipe (outer φ = 61 mm , t = 7 mm) |

| Front supports |

MS pipe (outer φ = 48 mm, t = 5 mm) |

| Diesel engine, bearings and tyres |

Standard items purchased from the market |

breastplate was bolted with frame. The gapbetween the breastplate and beater blades was regulated up to a few millimetres to accomplish one hand decortication. The raspador has 18 beater blades on its periphery. A diesel engine of 7.5 kW (10 hp) was employed to run this machine. The prototype machine is shown in Figure 2.

Theoretical design of raspador

When a leaf is introduced between raspador blades and breastplate (Figure 3, Left), the beater blades progressively smash the leaf at closely spaced intervals and chip off it against the breastplate by beating principle. This beating action continues as the leaf is still inside the raspador. Due to impact force of blades, the parenchyma cells and vascular tissues of the leaf are softened. The continuous beater action scraps away pulpy material and reveals fibre. The kinematic principle of raspador is shown in Figure 3 (Right) (Kanogu et al., 2011).

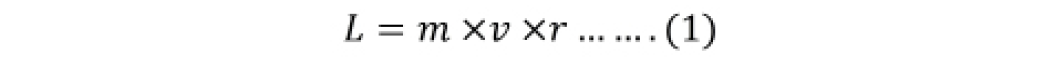

The raspador can be driven with a certain rotation speed for effective decortication. The angular momentum developed at the tip of the beating blade can be determined from Equation 1:

where, L is angular momentum (kg.m2 s-1), m is the mass of raspador (kg), v is the linear velocity of the blade tip (m s-1) and r is the radius of raspador from origin to blade tip (m).

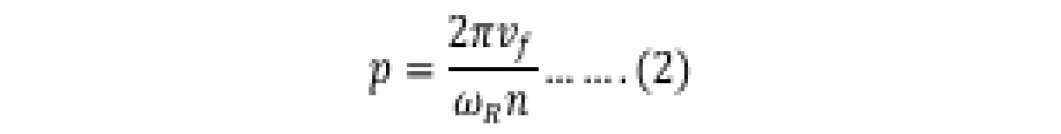

The quality of decortication can be assessed by the pitch of decortication. The pitch represents the quantity of leaf material that is scraped off every time a beater blade interacts with the sisal leaf. The pitch was determined using Equation 2 (Kanogu et al., 2011; Snyder et al., 2006):

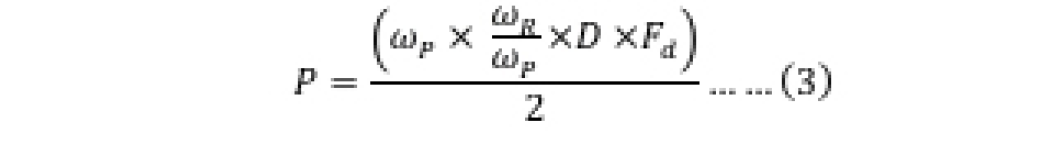

where, p is the pitch distance of decortication (m), vf is the feed velocity of leaf (m s-1), wR is the angular speed of raspador (rad s-1) and n is the number of blades on the raspador periphery. In this design, the pitch of decortication was controlled by the push of operator. The power required for decortication process was determined using Equation 3 (Kanogu et al., 2011; Snyder et al., 2006):

where, P is the power required for decorticating process (W), wp is the angular speed of prime mover (rad s-1), D is the diameter of raspador (m) and Fd is the decortication resistance (N). The decortication resistance is a function of time (s), raspador rotational speed ωR (rad s-1) and the decortication gap (m) between beater blades and breastplate.

Performance evaluation

The performance of prototype sisal decorticator was evaluated at Agricultural and Biological Engineering Institute, NARC, Islamabad. Fresh sisal leaves were cut and transported for testing the machine. Two persons were needed for operating this machine: one for feeding sisal and the other for bringing sisal leaves close to the feeding person and for removing the waste. Sisal leaves were fed manually between the raspador and breastplate and the fibre was produced by the scrapping action of beater blades. Sisal leaves were fed in the machine from the tip ends first and reversed the decorticated part by feeding the butt ends for complete decortication. The removed material was turned out as pulp and was thrown in the chute from the lower end of raspador. Moisture content of leaves was determined using gravimetric method (oven dry method) by placing samples in an oven for 24 hours at 104°C (Naik et al., 2013a). About 15 kg sisal leaves were used in each test and a total of 15 tests were conducted to evaluate the performance of machine. Dimensions of leaves and fibres were determined using a measuring tape. Weight of sisal leaves and fibres was determined with a digital electric balance. Rotation speeds of engine and raspador were determined using a tachometer. Decortication resistance (Fd) was determined by pressing the blunt blade on sisal leaves till the decortication started as shown in Figure 4.

Results and Discussion

Specifications of the machine are shown in Table 2.

Relation between raspador speed and sisal decortication quality was studied with varying decortication gap between the breastplate and blades. For a specific

Table 2: Specifications of sisal decorticator

| Particulars | Specifications |

| Overall length | 2020 mm |

| Overall width of machine | 660 mm |

| Width of machine form wheels | 1145 mm |

|

Height of machine |

1220 mm |

| Working height of machine | 810 mm |

| Diameter of raspador (cylinder) with cutters | 530 mm |

| Width of raspador blades | 455 mm |

| Width of raspador blades including side plates | 470 mm |

| Number of blades | 18 |

| Rotation speed of cylinder | 1000-1500 rpm (Average = 1250 rpm) |

| Average linear velocity of blades |

34.7 m s-1 |

| Engine power | 7.5 kW (~ 10 hp) |

| Weight of machine | 300 kg |

| Transportation of machine | Tractor hitch |

decortication gap, 10 replications were taken on each raspador speed to study the fibre quality. The machine was operated from 1000 rpm to 1500 rpm and the gap was varied from 1 mm to 5 mm. Sisal decortication process was also studied at a lower raspador speed (< 1000 rpm), but the decortication process was not found so effective. The reason is that the sisal leaf is very strong, which requires an enormous force to chip off flesh material to yield fibre. The relation between raspador speed, decortication gap and the quality of fibre is shown in Table 3. The quality of decortication was depended on the gap between breastplate and beater blades and raspador speed. The optimal gap between raspador blades and breastplate was determined as 2 mm. By changing this gap, the quality of decortication was affected. For example, by keeping the gap less than 2 mm, the fibre was broken during decortication process. By increasing this gap, un-decorticated sisal was left in the fibre. Similarly, at a higher raspador speed, the fibre breakage was up to 25 %, when compared with the fibre extracted at 1250 rpm (Table 3). The optimum speed of the raspador having < 10% fibre breakage was 1250 rpm. At this speed, the leaf was hit 375 times per second by beater blades. Many short fibres were slipped into the raspador owing to loose grip on the slippery fibres while reversing the leaves. Some fibres were also broken due to strong impact force of beaters on leaves and due to narrow gap between the breastplate and rotating blades. Naik et al. (2013a) reported fibre losses up to 10 % in raspador decorticators. In this study, the fibre loss was about 10 %, which increased up to 25 % by decreasing the decortication gap (< 2 mm) or by increasing the raspador speed (> 1250 rpm). Sisal plants are shown in Figure 5 (Left), whereas the fibre extracted by the prototype sisal decorticator is shown in Figure 5 (Right).

Table 3: Relation of raspador speed, decortication gap and the quality of sisal fibre

| Raspador speed (rpm) | Clearance or gap | Fibre breakage | Length of fibre (mm) | Quality of fibre |

| 1000 | < 2 mm | High | ≥ 1200 | CBF* |

| 1100 | High | ≥ 1200 | CBF | |

| 1200 | High | ≥ 1200 | CBF | |

| 1300 | High | ≥ 1200 | CBF | |

| 1400 | High | ≥ 1200 | CBF | |

| 1500 | High | ≥ 1200 | CBF | |

| 1000 | 2 mm | Low | ≥ 1300 | CBF** |

|

1100 |

Low | ≥ 1300 | CBF | |

| 1200 | Low | ≥ 1300 | CBF | |

| 1300 | Medium | ≥ 1200 | CBF | |

| 1400 | High | ≥ 1200 | CBF | |

| 1500 | High | ≥ 1200 | CBF | |

| 1000 | > 2 mm | Low | ≥ 1400 | UF*** |

| 1100 | Low | ≥ 1400 | UF | |

| 1200 | Low | ≥ 1400 | UF | |

| 1300 | Low | ≥ 1300 | UF | |

| 1400 | Medium | ≥ 1300 | UF | |

| 1500 | Medium | ≥ 1300 |

UF |

* CBF = Clean and broken fibre; **CF=Clean fibre; ***UF=Unclean fibre.

The decortication pitch was depended on the skill of the operator. Keeping the fibre in contact with raspador for a longer period, the amount of breakage was more. Better decortication was achieved, if the leaf was inserted in the machine and removed in no time. Snyder et al. (2006) developed a sisal decorticator, where pitch was controlled by the force of gravity. The sisal leaf was fed from the top and leaf was travelled down by gravity force. However, the performance of this machine was not thoroughly compared with other machines, which is the limitation of this study.

Results revealed that the fresh fibre content in sisal leaves was 10.1 % of total green leaf weigh, but the dried fibre content was 3.2 % of total green leaf weight. These results are consistent with those of Kawongolo et al. (2002), who reported the dry fibre yield of 3.2 %. This result is also consistent with those of Srinivasakumar et al. (2013), who reported 3.0 % dry fibre content in sisal leaves. Similarly, Naik et al. (2013a and b) reported that the dry fibre content varies from 3 to 5 % of the green leaf weight. The length of sisal leaves varied from 1100 mm to 1700 mm in this study was as those varied by Naik et al. (2013a and b) and Srinivasakumar et al. (2013). Fibre extraction capacity of this machine was 15.94 kg h-1 dry sisal fibre. The output capacity of sisal fibre was better than that of reported by Naik et al. (2013b), where the output capacity of sisal fibre was only 9-10 kg h-1. Cantalino et al. (2015) reported the processing capacity of such sisal decorticators between 15 to 20 kg h-1 of dry sisal fibre. Average time for decorticating one leaf was 9 seconds and average fibre length was 1349 mm. Mohanti et al. (2005) reported that the diameter of fibre ranges from 100 to 300 μm and length of fibre ranges from 600 to 1500 mm (0.6 to 1.5 m). Results of all tests are shown in Table 4.

Summary of mean parameters of leaves and results of machine performance are presented in Table 5. The mass of leaves ranged from 1.300 to 1.600 kg per leaf in all tests. Power required to decorticate sisal leaves was ranged from 1.7 to 4.8 kW from tip to butt ends, respectively. This is evident that the butt ends took more power for decortication process. Moisture contents on butt, middle and tip ends of leaves were 85.0 %, 82.0 % and 76.0 % on wet basis, respectively. The decortication pitch of sisal leaves was 2.1 mm.

Operating cost and Break-Even Point (BEP)

The operating cost of sisal decorticator was calculated using its ownership cost (fixed cost) and variable cost. The operating cost was calculated based on the selling price of the fibre. It was assumed that sisal crop is wild in Pakistan, which is free of cost. However, its cutting, transportation, decortication, drying and combing operations involve costs. After decortication process, fibre was processed in a combing machine, which brushed, cleaned and straightened the fibre for selling it in the market. Therefore, for calculating the operating cost of sisal decorticator, the fixed and variable costs of the combing machine were also included in calculations. Total purchase price of sisal decorticator and combing machine was Rs. 250,000. The fixed cost of both machines was Rs. 134.8 h-1, whereas the variable cost was Rs. 373.1 h-1. Total operating cost of both machines was Rs. 507.9 h-1. The selling price of good quality fibre produced in this process was assumed to be Rs. 150 kg-1 based on international market.

Table 4: Results of all sisal decortication tests

| Test No. | Weig ht of leav es (kg) | Leaf length (mm) ± SD | Leaf weight (g) ± SD | Fibre length (mm) ± SD | Fresh fibre weight (g) ± SD | Dry fibre weight (g) ± SD | Fresh fibre content (%) ± SD | Dry fibre content (%) ± SD | Crush ing capa city (kg/h) |

| 1 | 11.0 | 1391± 39.7 | 1100± 58.7 | 1300±73.8 | 124±15.2 | 36±4.2 | 11.3±1.1 | 3.3±0.4 | 492.5 |

| 2 | 17.1 | 1425± 18.0 | 1710± 43.0 | 1305±70.9 | 184±26.1 | 41±9.6 | 10.8±1.7 | 2.4±0.6 | 496.2 |

| 3 | 14.0 | 1350± 42.4 | 1400± 23.5 | 1252±83.2 | 155±16.6 | 42±9.1 | 11.1±1.2 | 3.0±0.7 | 472.3 |

| 4 | 17.0 | 1372± 39.6 | 1700± 40.0 | 1262±71.9 | 222±35.6 | 47±9.1 | 13.1±2.2 | 2.8±0.6 | 502.2 |

| 5 | 16.0 | 1400± 25.5 | 1600± 38.1 | 1285±69.6 | 200±31.6 | 45±7.9 | 12.5±1.8 | 2.8±0.5 | 506.1 |

| 6 | 17.5 | 1474± 51.3 | 1750± 45.8 | 1413±57.2 | 176±24.1 | 43±9.7 | 10.1±1.3 | 2.5±0.6 | 495.9 |

| 7 | 15.0 | 1395± 12.2 | 1500± 43.6 | 1350±69.3 | 138±13.0 | 52±8.4 | 9.2±1.0 | 3.5±0.6 | 488.3 |

| 8 | 18.5 | 1443± 31.1 | 1850± 55.7 | 1386±93.0 | 186±24.1 | 50±7.9 | 10.1±1.2 | 2.7±0.4 | 492.6 |

| 9 | 17.5 | 1520± 28.3 | 1750± 38.7 | 1424±88.8 | 161±19.5 | 72±5.7 | 9.2±1.2 | 4.1±0.3 | 509.7 |

| 10 | 16.5 | 1425± 43.3 | 1650± 45.8 | 1384±41.6 | 135±18.0 | 65±7.9 | 8.2±1.2 | 3.9±0.4 | 512.6 |

| 11 | 18.1 | 1420± 36.7 | 1805± 39.1 | 1392±75.0 | 152±13.0 | 58±5.7 | 8.4±0.7 | 3.2±0.3 | 499.1 |

| 12 | 15.0 | 1429± 23.6 | 1500± 53.4 | 1406±37.8 | 139±16.7 | 34±7.4 | 9.3±1.2 | 2.3±0.5 | 495.2 |

| 13 | 15.5 | 1430± 19.7 | 1550± 66.3 | 1385±68.4 | 145±11.2 | 34±8.9 | 9.4±0.8 | 2.2±0.6 | 500.6 |

| 14 | 10.1 | 1495± 16.6 | 1010± 71.8 | 1445±79.5 | 110±15.8 | 49±8.2 | 10.9±1.3 | 4.9±0.5 | 501.7 |

| 15 | 15.0 | 1395± 35.9 | 1500± 41.8 | 1245±87.9 | 122±13.0 | 62±6.7 | 8.1±0.9 | 4.1±0.4 | 503.7 |

| Avg. | 15.6 | 1424.3 | 1558 | 1348.9 | 156.6 | 48.7 | 10.1 | 3.2 | 497.9 |

| SD | 2.4 | 45.3 | 241.8 | 67.7 | 31.5 | 11.4 | 1.5 | 0.8 | 9.7 |

Note: Each test contained 10 sisal leaves weighing about 15 kg sisal leaves. Standard deviations of parameters are shown in terms of ± values against each result, which indicate the ranges of those parameters.

Table 5: Summary of results of all tests

| Particulars | Mean specifications |

| Leaf mass (g) | 1558 |

| Leaf length with spine (mm) | 1424.3 |

| Leaf width at base (mm) | 101 |

| Maximum leaf width (mm) | 185 |

| Maximum leaf thickness (mm) | 36 |

| Fresh fibre weight per leaf (g) | 156.6 |

| Dry fibre weight per leaf (g) | 48.7 |

| Fibre length (mm) | 1348.9 |

| Fibre content of leaves (fresh) (%) | 10.1 |

| Fibre content of leaves (dry) (%) | 3.2 |

| Average moisture content (wb) of sisal leaves (%) | 81 |

|

Average crushing capacity of machine (kg h-1) |

497.9 |

|

Average dry fibre production capacity (kg h-1) |

15.94 |

| Average decortication pitch (mm) | 2.1 |

| Average decortication power (kW) | 3.1 |

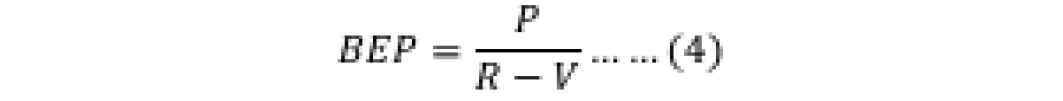

Break-even point (BEP) is a payback stage, where investment on machines gives positive return. Break-even point is a relationship among the purchase price of machines, their variable costs and their return, which is calculated using Equation 4:

where, BEP is break-even point per unit (hour), P is initial purchase price of machines (Rs.), R is revenue or income generated per unit (Rs. h-1) and V is the variable cost of machine per unit (Rs. h-1).

Table 6: Economic analysis of sisal decorticator based on some assumptions

| Parameters | Cost (Rs.) |

|

Cutting cost of sisal plants for one hour decortication, e.g. 498 kg (Rs. h-1) |

249.0 |

|

Transportation cost of 498 kg sisal leaves from wild areas to ABEI(Rs. h-1) |

498.0 |

|

Operating cost of sisal decorticator and combing machine (Rs. h-1) |

507.9 |

|

Labour cost of drying of fibre (Rs. h-1) |

62.5 |

|

Dry fibre content yield per hour (Rs. h-1) |

15.94 |

|

Total cost (Rs. h-1) |

1,317.4 |

|

Selling price 1 kg dry and good quality fibre (Rs. kg-1) |

150 |

|

Selling price of 15.94 kg dry fibre (one hour) (Rs. h-1) |

2,390.4 |

|

Net saving per hour (Rs. h-1) |

1,073.0 |

|

Net saving per 8 hour day (Rs. day-1) |

8,584.0 |

The BEP or payback time was 233 h, which means that after 233 h, investment cost of machines would be paid back to the user. After this stage, pure profit would be generated on further use of machines. Economic analysis of sisal decorticator based on different costs and assumptions is given in Table 6. Comprehensive evaluation of this technology should be performed in future for assessing statistical significance of this technology.

Conclusions

A small-scale sisal decorticator was designed, developed and evaluated. Sisal fibre production capacity of this machine was 15.94 kg h-1 (dry fibre). Dry fibre content was 3.2 %. Average power to decorticate sisal plants was 3.1 kW and average moisture content of leaves was 81 % (wb). The decortication pitch was 2.1 mm. The length of fibre was 1348.9 mm. Operating cost of sisal decorticator together with a combing machine was Rs. 507.9 h-1. The break-even point or payback period of this technology was 233 h. Sisal fibre is suitable for making ropes, carpets and other domestic and industrial products. It is concluded that this technology has a great potential for getting economic benefits and it needs to be commercialised in sisal growing areas of the country. Awareness should be created in the local sisal producing farmers for generating employment opportunities and gaining economic benefits. This technology should be efficient, cost-effective and affordable to small-sale farmers.

Acknowledgements

We highly thank and appreciate Lok Sanjh Foundation, a local None-Government Organisation (NGO), for funding this project. They also conducted different national/international seminars and field days in the country for creating awareness among farmers about the importance of sisal crop.

Author’s Contribution

TA and SZ concieved the idea. ZA collected the date while MZK analysed it. TA and HSM wrote the article. TA, HSM and ZA provided machine febrication. HSM, TA and SZ provided technical input at every step.

References

Akin, D.E., D.S. Himmelsbach and H.W. Morrison. 2000. Biobased fiber production: Enzyme retting for flax/linen fibers. J. Polym. Environ. 8(3): 103-109. https://doi.org/10.1023/A:1014886631052

Brenters, J. 2000. Design and financial assessment of small scale sisal decortication technology in Tanzania. MSc Thesis, Faculty of Technology Management, Eindhoven University of Technology, Eindhoven, the Netherlands.

Cantalino, A., E.A. Torres and M.S. Silva. 2015. Sustainability of Sisal cultivation in Brazil using co-products and wastes. J. Agri. Sci. 7(7): 64-74. https://doi.org/10.5539/jas.v7n7p64

Chand, N. and P.K. Rohatgi. 1994. Natural fibres and their composites. Periodical Experts Book Agency, Delhi, India. Pp. 128.

FAO. 2013. Jute, kenaf, sisal, abaca, coir and allied fibres. Statistics 2013. FAO Corporate Document Repository, Rome, Italy.

Kanogu, M.H., O.V. Antony and K.J. Kiguru. 2011. Development of a sisal decorticator for small holder farmers/traders: redesign, fabrication and field testing. Final project report. University of Nairobi, Kenya: 52.

Kawongolo, J.B., J. Sentong-Kibalama and L. Brown. 2002. Design of a decorticator for small scale sisal processing in Uganda. Proceedings of American Society of Agricultural and Biological Engineers, Paper No. 026202, ASABE Annual Meeting. https://doi.org/10.13031/2013.10304

Leão, A., S.M. Sartor and J.C. Caraschi. 2006. Natural fibre based composites – Technical and social issues. Mol. Cryst. Liq. Cryst. 448(1): 161–177. https://doi.org/10.1080/15421400500388088

Lock, G.W. 1969. Sisal, thirty years sisal research in Tanzania, 2nd Ed., Longmans, Green and Co. Ltd, London.

Mohanty, A.K., M. Manjusri and L.T. Drzal. 2005. Natural fibres, Biopolymers and Biocomposites. CRC Press, Taylor and Francis Group, Boca Raton.

Müssig, J. 2010. Industrial Applications of Natural Fibres. John Wiley & Sons, Ltd., Chichester, UK. https://doi.org/10.1002/9780470660324

Mwaikambo, L.Y. 2006. Review of the history, properties and application of plant fibres. Afr. J. Sci. Tech. 7(2): 120-133.

Naik, R.K., R.C. Dash and A.K. Goel. 2013a. Mechanical properties of sisal (A. sisalana) relevant to harvesting and fibre extraction. Int. J. Agri. Eng. 6(2): 423-426.

Naik, R.K., R.C. Dash and S.C. Pradhan. 2013b. Sisal fibre extraction: methods and machine development. Agri. Eng. Today. 37(4): 27-30.

Shamte, S. 2000. Overview of the sisal and henequen industry: A producers’ perspective. Proceeding of a seminar held by the Food and Agriculture Organisation of the United Nations (FAO) and the Common Fund for Commodities (CFC), Rome, Italy.

Smole, M.S., S. Hribernik, K.S. Kleinschek and T. Kreže. 2013. Plant fibres for textile and technical applications. P. 369-397. In. S. Grundas and A. Stepniewski (ed.), Advances in Agrophysical Research, InTech, Publishing.

Snyder, B.J., J. Bussard, J. Dolak and T. Weiser. 2006. A Portable sisal decorticator for Kenyan farmers. Int. J. Service Learn. Eng. 2(1): 92-116.

Srinivasakumar, P., M.J. Nandan, C.U. Kiran and K.P. Rao. 2013. Sisal and its potential for creating innovative employment opportunities and economic prospects. IOSR J. Mech. Civ. Eng. 8(6): 1-8. https://doi.org/10.9790/1684-0860108

To share on other social networks, click on any share button. What are these?