Determinants of Technical Efficiency of Tomato Farms in District Peshawar, Khyber Pakhtunkhwa

Determinants of Technical Efficiency of Tomato Farms in District Peshawar, Khyber Pakhtunkhwa

Shahid Ali1*, Asim Khan1, Aftab Khan1 and Bakhtawar Riaz2

1Department of Agricultural and Applied Economics, The University of Agriculture, Peshawar, Khyber Pakhtunkhwa, Pakistan; 2Department of Economics, The University of Haripur, Khyber Pakhtunkhwa, Pakistan.

Abstract | This study was directed in district Peshawar, Khyber Pakhtunkhwa, Pakistan. This study evaluated technical efficiency of tomato farms and to catch factors if any causing technical inefficiency in tomato production. 90 farmers were selected through multi-stage proportional allocation sampling techniques. Data was collected by using a well-structured interview schedule. Cobb-Douglas production function was employed to assess technical efficiency. Maximum likelihood estimation techniques were employed for estimation. Results showed that all explanatory variables except pesticides have significant effect on tomato production. The results showed that a 1% increase in seed rate, labor, tractor hours, urea, DAP and irrigation increases output by 0.81, 0.02, 0.28, 0.14, 0.25 and 0.02 percent, respectively. Mean technical efficiency score was found 95% ranges from 86% to 99%. This means an average farmer can increase tomato output by 4% with available resources and technology. Results of inefficiency effect model indicated that farmers’ experience has negative and significant relationship with technical inefficiency. Efforts should be made to keep experience farmers in tomato farming. Government also needs to allocate more funds for extension services to provide formal and informal education to tomato growers.

Received | January 15, 2019; Accepted | March 15, 2019; Published | May 07, 2019

*Correspondence | Shahid Ali, Department of Agricultural and Applied Economics, The University of Agriculture, Peshawar, Khyber Pakhtunkhwa, Pakistan; Email: [email protected]

Citation | Ali, S., A. Khan, A. Khan and B. Riaz. 2019. Determinants of technical efficiency of tomato farms in district Peshawar, Khyber Pakhtunkhwa. Sarhad Journal of Agriculture, 35(2): 572-578.

DOI | http://dx.doi.org/10.17582/journal.sja/2019/35.2.572.578

Keywords | Tomato, Technical efficiency, MLE Techniques, Cobb- Douglas production, Function, Peshawar-Pakistan

Introduction

Pakistan is an agricultural country, it has fertile land, best irrigation system, well irrigated plains, and infrastructure, different type of weather, and old experiences of farming (Mari and Lohano, 2007). Agriculture has vital role in the economic development of the Pakistan. It contributes 18.9 percent to Gross Domestic Product (GDP) and observe 42.3 percent of labor force, 68 percent rural population depend directly or in directly on agriculture (GoP, 2018).

Tomato (lycopersicon Escolentum) is a commodity, usually in red color. It is originated from South American Andes but usage as an edible commodity started in Mexico and then spread throughout the world. Tomatoes add to a healthy, balanced diet. Good source of mineral, essential amino acids, vitamins, sugars and nutritional fibers. Its total production during 2017 was 601.098 thousand tons (GoP, 2017).

According to FAO in 2017 the top 10 tomato producing countries were China followed by India, United State, Turkey, Egypt, Iran, Italy, Brazil, Spain, and Mexico whose total production was 123 million tons out of 163 million of the world. Netherland is the leading tomato exporting country in the world followed by Mexico, Spain, Turkey, France, Morocco, Jordon, United State, Canada and Belgium. In 2017 Pakistan is ranked 33rd with production was estimated 601.098 thousand tons. Total tomato cultivated area in 2017 was reported about 63.203 thousand hectares (FAO, 2017).

The literature declared with growth rate 1.95, there is net addition of 3.7 million people each year. Therefore, there is need to enhance the farm level efficiency to meet the domestic needs and save foreign exchange. Efficiency in productivity can be achieved by finding out technical efficiency level of tomato growers and factors, if any, affecting inefficiency of tomato growers. Farmer’s efficiency and productivity are very important factors for maximizing profit and formulating future policy and farming management. The study is hence planned to evaluate and examine technical efficiency of tomato growers in the study area.

Materials and Methods

Data

The study was instigated district Peshawar of Khyber Pakhtunkhwa, Pakistan. Primary data was obtained from sampled tomato growers (Figure 1). Multi-stage sampling technique was used where 90 respondents were selected through proportion allocation techniques (Cochran, 1977). Information regarding input such as seed, tractors hours, labor, Urea, FYM, irrigation and pesticides and socioeconomics characteristic like age, education, experience, area etc were taken under consideration.

Theoretical frame work

Farmer efficiency is very vital to economist to deal the how to increase output with the given inputs as evaluated by Battese and Coelli in 1995. The quantity of productivity and efficiency came into use from Koopmans (1951) and Debreu (1951) study that was prolonged by Farrell (1957), who further separated economic efficiency into two classes, allocative efficiency and technical efficiency. Technical efficiency gives statistics regarding variation that exists among farmers production. It’s actually measures the gap between farmers real yield and the yield that can be produced by using the farm resources efficiently. The allocative efficiency is getting maximum output by using cost minimizing input. The product of technical efficiency and allocative efficiency yields economic efficiency (Farrell, 1957).

Model specification

To estimate technical efficiency parametric and non-parametric techniques can be used. Parametric approach use econometrics measures however non parametric method (DEA) used mathematical practices to assess technical efficiency. Both methods has it advantages and disadvantages as Battese (1992), Bravo-Ureta and Pinheiro (1997) and Coelli and Perelman (1999) clarified the benefits and weaknesses of each models. Where parametric approach is probabilistic that retain distinction between natural random error and farm specific technical inefficiency whereas non-paramatric has the random noise and technical inefficiency together. Paramatric model confines misspecification of functional form like technology and inefficiency, whereas the non-paramatric is less accountable to such effect (Ali and Khan, 2014).

It is established from literature that for assessing technical efficiency of farms/firms the econometric model was frequently and extensively utilized. Stochastic frontier production analysis is used due to its composite structure of errors which also projected using maximum likelihood techniques (MLE).

Stochastic frontier analysis

The stochastic frontier approach given in Equation (1) was autonomously planned by Aigner et al. (1977) and Meeusen and Van den Broeck (1977). The well-designed formula is given below.

Yi = f (Xi : βi) + εi i = 1, 2, 3, 4, ......., n ….(1)

Where;

Yi = Tomato yield kg acre -1; f ( )= Production function; Xᵢ = used inputs units acre -1; βᵢ = Expected coefficient; εi = νi – μi; εi = Composed error term; νi = random error; μi = farm/farmer specific errors; νi, represent the random error effects, errors in measurement, erroneous regressors and statistical errors. µi has linkage with the technical inefficiency of farms/firms and ranges from zero to one (Khan, 2012).

Empirical model

Following Donkoh et al. (2008), Hussain et al. (2011), Khan (2012), Khan and Ghafar (2013), Tsoho, et al. (2012), Usman and Bakari (2013), Haile (2015), Tegar et al. (2016), Wahid et al. (2017), Tabe-Ojong and Molua (2017) and Mamary et al. (2018) empirical model for Cobb-Douglas type function was estimated as per Equation 2. The econometrics software STATA-12 was employed for estimation of Equation 2 and 3.

ln Yi = β0 + β1 ln Seed + β2 ln TractorHrs + β3 ln Labor + β4 ln Urea + β5 ln Fym + β6 ln IrrigNo + β7 ln Pesticides + εi ….(2)

Where;

Y = Tomato Yield in kg acre -1; Seed = Seeds sown in kg acre -1; TractorHrs = Tractor Hours acre -1; Labor = Labor days acre -1; Urea = Urea in kg acre -1; Fym = Farm Yard Manure in kg acre -1; Irrig = Number of irrigation acre -1; Pesticides = Pesticides/weedicides acre -1; Ln = Natural logarithm; εi = νi – μi; νi = Random error; μi = Technical inefficiency error term; βₒ and βᵢ = Coefficients estimated.

Technical inefficiency

Following Battese and Coelli (1995), Hussain et al. (2011), Khan (2012), Khan and Ghafar (2013), Tegar et al. (2016), Wahid et al. (2017), Tabe-Ojong and Molua (2017) and Mamary et al. (2018) inefficiency model was specified as given below in Equation (3).

μi =αₒ + α₁ AGE + α₂ FARMEXP + α₃ EDUC + α₄ AREA + α5 DAP + α6 COP + ώᵢ ….(3)

Where;

µᵢ = Technical inefficiency error term; AGE = Age of farmers (years); FARMEXP = Farm experience of farmers (years); EDUC = Education of farmers (years); AREA = Area under tomato (acres); DAP = Di Ammonium Phosphate (kg acre -1); COP = Cost of production of tomato (PKR acre -1); αᵢ = expected coefficients; ώᵢ = Random error normally distributed with zero mean and constant variance.

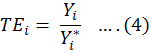

The formula for calculation of technical each tomato grower is given in Equation (4).

Where;

TEi = technical efficiency of each former that rangers from 0 to 1; Yi = Observed output of each farm; Yi*= Frontiers output of each farm.

For technical inefficiency of singular grower, the formula is given in Equation (5).

Results and Discussion

Descriptive statistics of the variable in technical efficiency model

Table 1 shows descriptive statistics of variable used for estimation of technical efficiency model of tomato growers in district Peshawar. The variable used for technical efficiency were seed rate per acre, tractor hours, labors, FYM, Urea, pesticides, Irrigation, farmer experience, farmer age, education of the farmer (socioeconomics characteristic), area under tomato, DAP used to take as Dummy and cost of production. The average yield of tomato in the study area calculated was 5415.66 kgs per acre, ranging from 4480 to 6300 kgs per acre with standard deviation of 433.85 kgs. Average seed rate was 333.55 gms per acre with maximum of 350 gms and minimum of 300 gms per acre. The average tractor hours used in the study area was 6.56 hrs ranging from 4 to 10 hrs. Average number of labor was 54.8 man days, ranging from 51 to 58 manual days with a standard deviation of 2.09 man days. The average application of urea was 135.27 kgs ranging from 100 to 175 kgs per acre while the average used of FYM was 6595.55 kgs with a minimum of 6200 kgs and a maximum of 7000 kgs per acre. The average number of irrigation was 8.73 ranging from 6 to 12 per acre. The mean application of pesticides was 4.54 liters with a minimum of 3 liter and a maximum of 6 liter per acre.

Table 1: Summary statistics analysis of variable.

| Variable | Unit | Mean | Min | Max | S.D. |

| Y (output) | Kgs | 5415.66 | 4480 | 6300 | 433.85 |

| X1(seed rate) | Gms | 333.55 | 300 | 350 | 10.84 |

| X2 (tractors hrs) | Hrs | 6.58 | 4 | 10 | 1.87 |

| X3 (labor) | MD | 54.80 | 51 | 58 | 2.09 |

| X4 (urea) | Kgs | 135.27 | 100 | 175 | 23.37 |

| X5 (FYM) | Kgs | 6595.55 | 6200 | 7000 | 268.12 |

| X6 (No of irrigation) | No | 8.73 | 6 | 12 | 2.17 |

| X7 (pesticides) | Lit | 4.54 | 3 | 6 | 0.99 |

|

Z1 (Age) |

Yrs | 40.33 | 24 | 62 | 9.51 |

|

Z2 (Education) |

Yrs | 6.37 | 0 | 12 | 3.4 |

|

Z3 (Experience) |

Yrs | 13.97 | 2 | 32 | 6.94 |

|

Z4 (Area) |

Acre | 1.47 | 1 | 2.5 | 0.485 |

|

Z5 (DAP) |

Kgs | 78.62 | 50 | 125 | 25.14 |

|

Z6 (Total Cost) |

Rs | 105565.1 | 79500 | 138500 | 15816 |

Source: Authors’ estimates from survey data, 2018.

MLE results of Cobb-Douglas type production function

Table 2 represents the results of technical efficiency and inefficiency of tomato growers in district Peshawar. The results revealed that all the explanatory variable except pesticides significantly affect tomato yield. The MLE estimated that seed rate, labor, tractor hours, urea, DAP, and irrigation had significant and had positive relationship with tomato production. The results showed that seed rate, labor, tractor hours, urea, DAP, and irrigation had propensity to increase technical efficiency as one percent increase in these factor would raise tomato yield by 0.81, 0.02, 0.28, 0.14, 0.25 and 0.02 percent, respectively. The coefficient of pesticide is -0.01 and statistically insignificant. This negative coefficient may be due to over utilization of pesticide while the farmer is in irrational stage III of production (Debertin, 2012) where MVP<MFC. It is needed to reduce the use of pesticide in the research area to that point where marginal value of product is in equilibrium with marginal factor cost MVP=MFC. These results are in line with Ali and Khan (2014), Shaheen et al. (2011), Oyewo (2011), Singh (2007), and Hassan and Ahmad (2005).

Table 2: MLE results of Cobb-Douglas type production function.

| Var | Co-efficients | Standard. Errors | t-ratios | p-values |

| Constant | -0.27 | 0.791 | -0.34 | 0.73 |

| X1 (seed rate) | 0.81 | 0.116 | 6.94 | 0.00 |

| X2 (tractors hrs) | 0.02 | 0.009 | 2.23 | 0.02 |

| X3 (labor) | 0.28 | 0.075 | 3.79 | 0.00 |

| X4 (urea) | 0.14 | 0.022 | 6.72 | 0.00 |

| X5 (FYM) | 0.25 | 0.091 | 2.75 | 0.05 |

| X6 (No of irrigation) | 0.02 | 0.012 | 1.93 | 0.05 |

| X7 (pesticides) | -0.01 | 0.009 | -1.06 | 0.29 |

Source: Authors’ estimates from survey data, 2018.

MLE results of technical inefficiency effect model

The estimates of technical inefficiency are shown in Table 3. There is positive relationship between farmer age and technical inefficiency and are statistically significant that implied that an increase of farmer age the technical inefficiency increases while technical efficiency decreases. The estimated result revealed that there is negative and significant relationship of farmer experience with technical inefficiency that implied that an increase in farmer experience the technical inefficiency decreases and technical efficiency increases, this result is in collaboration with Khan and Ali (2013) as well as Mustapha and Sallihu (2015). The relationship of education, area under cultivation and DAP with technical inefficiency is negative and insignificant, the results are in strong agreement with Adigbite and Adeoye (2015), Soloman et al. (2015) and Gichimu et al. (2015). The relationship of cost of production of tomato crop with technical inefficiency is positive and statistically insignificant. Its mean that cost of production has no effect on technical efficiency, same result was also found by Ali and Khan (2014).

Table 3: MLE results of technical inefficiency effect model.

| Variables | Coefficients | Std. Errors | t-ratios | p-values |

| Constant | -10.45 | 4.04 | -2.59 | 0.01 |

|

Z1 (Age) |

0.25 | 0.12 | 1.89 | 0.059 |

|

Z2 (Education) |

-0.23 | 0.16 | -1.37 | 0.171 |

|

Z3 (Experience) |

-0.37 | 0.18 | -2.04 | 0.042 |

|

Z4 (Area) |

-1.24 | 1.57 | -0.79 | 0.432 |

|

Z5 (DAP) |

-1.73 | 0.99 | -1.73 | 0.083 |

|

Z6 (Total Cost) |

1.72 | 1.64 | 1.05 | 0.295 |

| MLE of the variance parameters | ||||

|

sigma2 |

0.001 | 0.000 | ||

| Lambda | 2.208 | 0.006 | ||

| Gamma | 0.688 | |||

Source: Authors’ estimates from survey data, 2018.

Table 4: Frequency distribution of technical efficiency of individual tomato growers.

| TE | No | Percentage |

| 0.86-0.94 | 1 | 1.11 |

| 0.94-0.96 | 8 | 8.88 |

| 0.96-0.98 | 27 | 30.00 |

| 0.98-1 | 54 | 60.00 |

| Maximum | 99 | |

| Minimum | 86 | |

| Mean | 95 | |

Source: Authors’ estimates from survey data, 2018.

The results of maximum likelihood estimate explained variance parameter that is gamma with a value of 0.68 showed that out of total variation in production 68 percent is due to technical inefficiency U1 of the farmers in the study area, and the remaining 32 percent is due to natural uncertainty factor V1.

Frequency distribution of technical efficiency of individual tomato farms

Table 4 shows the frequency distribution of technical efficiency of individual tomato farms. The mean technical efficiency calculated is 0.95 with a maximum value of 0.99 and with a minimum of 0.86.

The results declare that there is a potential gain among the tomato grower and in short run the production of tomato can be increased by 5 percent in the study area. The study revealed that majority of the farmer that are 60 percent have technical efficiency above 98 percent, 10 percent tomato respondent have technical efficiency below 96 percent and 30 percent have technical efficiency between 96 and 98 percent.

Conclusions and Recommendations

Result revealed that seed rate, tractor hours, labor days and fertilizer are important factors for increasing tomato production in the study area. In inefficiency factors, farmers’ experience exhibits a negative relationship with technical inefficiency. This means that farming experience is a significant factor that decreases technical inefficiency of tomato growers. Based on the findings of this study it is recommended that extension personals should motivate tomato growers to increase seed rate, tractor hours and DAP application to enhance tomato productivity. It is recommended that government should encourage experienced farmers in tomato farming. As tomato is cash crop and labor intensive so provision of credit to farmers on easy terms and conditions for purchase of costly inputs will enhance tomato production.

Author’s Contribution

Dr. Shahid Ali developed main idea of this study, helped in analysis and interpretation of results. Wrote theoretical framework and abstract of the manuscript. Asim Khan collected and analyzed data, wrote results and discussions under the supervision of Dr. Shahid Ali. Aftab Khan helped in data collection, model specification and statistical analysis. Bakhtawar Riaz reviewed literature, corrected references and helped in comparison of results. All authors read and approved the final manuscript.

References

Adegbite. O. and I.B. Adeoye. 2015. Technical efficiency of pineapple production in Osun State, Nigeria. Agric. on-line Pap. Econ. Informatics. 7: 3-12.

Aigner, D., C.A.K. Lovell and P. Schmidt. 1977. Formulation and estimation of stochastic frontier production model. J. Econ. 6: 21–37. https://doi.org/10.1016/0304-4076(77)90052-5

Ali. E. And S. Ghaffar. 2013. Technical efficiency of tomato production in district Peshawar, Khyber Pakhtunkhwa, Pakistan. Am. Eurasian J. Agric. Environ. Sci. 13(11): 1465-1469.

Ali. S. And M. Khan. 2014. Technical efficiency of wheat production in district Peshawar, Khyber Pakhtunkhwa, Pakistan. Sarhad J. Agric. 30(4): 433-441.

Battese, G.E. 1992. Frontier production functions and technical efficiency: A survey of empirical application in agricultural economics. Agric. Econ. 7: 185-208.

Battese, G.E. and T.J. Coelli. 1995. A model for technical inefficiency effects in a stochastic frontier production function for panel data. Empirical Econ. 20: 325-332. https://doi.org/10.1007/BF01205442

Bravo-Ureta, B.E. and A.E. Pinheiro. 1997. Technical, economic, and allocative efficiency in peasant farming: Evidence from the Dominican Republic. Dev. Econ. XXXV-1: 48-67. https://doi.org/10.1111/j.1746-1049.1997.tb01186.x

Cochran, W.G. 1977. Sampling Techniques. 3rd ed. John wiley and sons inc. New York, USA.

Coelli, T. and S. Perelman. 1999. Comparison of parametric and non-parametric distance functions With application to European railways. Eur. J. Oper. Res. (EJOR). 117(2): 326-339. https://doi.org/10.1016/S0377-2217(98)00271-9

Debertin, D.L. 2012. Agricultural production economics, 2nd Edition. Macmillan publishing company, New York.

Debreu, E. 1951. The coefficient of resource utilization. Econ. 19(3): 273–292. https://doi.org/10.2307/1906814

Donkoh, S.A., M. Tachega and N. Amowine. 2008. Technical efficiency of tomato production: The case of Irrigation Company of Upper Region (ICOUR) in the Kasena Nankana district of Northern Ghana. Dep. Agric. Resour. Econ. Facul. Agric. Univ. Dev. Stud. Tamale, Ghana.

FAO. 2017. Food and Agriculture Organization of the United Nations. 2017. http//www.fao.org

Farrell, M.J. 1957. The measurement of productive efficiency. J. Royal Stat. Soc. 120: 253–81. https://doi.org/10.2307/2343100

Gichimu. L.K., I. Macharia and M. Meangi. 2015. Factor affecting technical efficiency of passion fruit producers in Kenya highlands. Asian J. Agric. Ext. Econ. Soc. 5(3): 126-136.

GoP. 2017. Ministry of national food and security research, Pakistan.

GoP. 2018. Pakistan economic survey, 2017-18. Ministry of finance, economic advisory wing, finance division, Islamabad, Pakistan.

Haile, B.T. 2015. Determinants of technical, allocative and economic efficiencies among onion producing farmers in irrigated agriculture: Empirical evidence from Kobo district, Amhara region, Ethiopia. Afr. J. Agric. Res. 10(20): 2180-2189. https://doi.org/10.5897/AJAR2015.9564

Hassan, S. and B. Ahmad. 2005. Technical efficiency of wheat farmers in mixed farming system of the Punjab, Pakistan. Int. J. Agric. Biol. 7(3): 431–435.

Hussain, N., A. Shahid, M. Naveed and S. Muhammad. 2011. An estimation of technical efficiency of garlic production in Khyber Pakhtunkhwa Pakistan. Int. Food Agric. Econ. 2(2): 169-178.

Khan, H. 2012. Measurement of technical, allocative and economic efficiency of tomato farms in northern Pakistan. J. Agric. Sci. Technol. 2: 1080-1090.

Khan, R.E.A. and S. Ghafar. 2013. Technical efficiency of tomato production: A case study of district Peshawar (Pakistan). World Appl. Sci. J. 28(10): 1389-1392.

Khan, H. and F. Ali. 2013. Productive efficiency of tomato growers in village Akbar Pura of district Nowshera in Khyber Pakhtunkhwa province of Northern Pakistan. Agric. Econ. 59(8): 381–388.

Koopmans, T.C. 1951. Activity Analysis of Production and Allocation. Jhon Wiley and Sons, Inc.

Mamary, K.A., J.K. Lagat, J.K. Langat and B. Teme. 2018. Determinants of technical efficiency of small scale vegetables production under different irrigation systems in Koulikoro and Mopti Regions, Mali. Am. J. Agric. For. 6(4): 71-77.

Mari, F.M. and H.D. Lohano. 2007. Measuring production function and technical efficiency of onion, tomato, and chillies farms in Sindh, Pakistan. Pakistan Develop. Rev. 46(4): 1053–1064.

Meeusen, W. and J. van den Broeck. 1977. Efficiency estimates from Cobb-Douglas production function with composed error. Int. Econ. Rev. 18: 435–444. https://doi.org/10.2307/2525757

Mustapha. A. and A. Salihu. 2015. Determinents of technical efficiency of maize/cowpea intercropping among women farmers in Gombe State, Nigeria. J. Agric. Sustainability. 7(2): 245-258.

Oyewo, I.O. 2011. Technical efficiency of maize production in Oyo State. J. Econ. Int. Finance. 3: 211-216.

Shaheen, S., M.H. Sial, G. Sarwar and R. Munir. 2011. Nexus between human capital and technical efficiency of cauliflower growers in soon valley, Punjab: A panel data analysis. Int. J. Humanit. Soc. Sci. 1 (14): 129–135.

Singh, S. 2007. A study on technical efficiency of wheat cultivation wheat cultivation in Haryana. Agric. Econ. Res. Rev. 20: 127-136.

Solomon, T., M. Yam and B. Begna. 2015. Gender differentials in scale and technical efficiencies among improved wheat variety growers in wheat belt of Ethiopia. J. Econ. Sustainable Dev. 6(1): 91-100.

Tabe-Ojong, M.P. Jr. and E.L. Molua. 2017. Technical efficiency of smallholder tomato production in semi-urban farms in Cameroon: A stochastic frontier production approach. J. Manage. Sustainability. 7(4): 27-35. https://doi.org/10.5539/jms.v7n4p27

Tegar, A., K.N.S. Banafar, A.K. Gauraha and G. Chandarkar. 2016. An analysis of technical and allocative efficiency of brinjal farm in Bilaspur district of Chhattisgarh: Agric. Update, 11(2): 96-103. www.researchjournal.co.in https://doi.org/10.15740/HAS/AU/11.2/96-103

Tsoho, B.A., O.A. Omotesho., S.A. Salauand and M.O. Adewumi. 2012. Determinants of technical, allocative and economic efficiencies among dry season vegetable farmers in Sokoto State, Nigeria. J. Agric. Sci. 3(2): 113-119.

Usman, J. and U.M. Bakari. 2013. Productıvıty analysıs of dry season tomato (lycopersiconesculentum mill.) productıon in Adamawa State, Nigeria. ARPN J. Sci. Technol. 3(5): 2225-7217.

Wahid, U., S. Ali and N.A. Hadi. 2017. On the estimation of technical efficiency of tomato growers in Malakand, Pakistan. Sarhad J. Agric. 33(3): 357-365. https://doi.org/10.17582/journal.sja/2017/33.3.357.365

To share on other social networks, click on any share button. What are these?