Field Performance Evaluation of Zone Disk Tiller Machine for Soil Physical Properties and its Relative Impact on Wheat Crop Recovery in Cotton Stubble field

Field Performance Evaluation of Zone Disk Tiller Machine for Soil Physical Properties and its Relative Impact on Wheat Crop Recovery in Cotton Stubble field

Muhammad Adnan Islam1,2*, Muhammad Iqbal2, Zia-ul-Haq2,3, Muhammad Mohsin Ali1, Hafiz Sultan Mahmood1, Shabbir Ahmed Kalwar1, Liaqat Ali Shahid1, Badar Munir Khan Niazi1 and Muzammil Husain1

1Agricultural Engineering Institute, Pakistan Agricultural Research Council (PARC), Islamabad, Pakistan; 2Department of Farm Machinery and Power, Faculty of Agriculture Engineering and Technology, University of Agriculture, Faisalabad, Pakistan; 3Faculty of Agriculture Engineering and Technology, PMAS Arid Agriculture University, Rawalpindi, Pakistan.

Abstract | Wheat and cotton are two most important crops of Pakistan. Due to late picking of cotton, wheat growing period is delayed and the farmers sown wheat in the December and January due to long process of field preparation by conventional method. Zone disc tiller machine developed in the department of Farm Machinery and Power, was employed for sowing wheat instead of conventional tillage in cotton stubble to avoid further late sowing of wheat. Zone disc tiller drill sows crop in strips. Strip tillage of soil reduced labour, fuel, irrigation and machinery costs. Zone disk tiller was tested for its field performance with three different types of furrow openers viz; disk furrow opener, reverse hoe furrow opener and hoe furrow opener. Statistical design, RCBD, was employed to evaluate the machine performance in comparison with conventional method of wheat sowing in cotton harvested field. In this study, moisture content (15.72 %), bulk density (1.41 g/cm3) and penetration resistance (875.21 kPa) were found 1.73, 1.23 and 1.48 times more under zone disc tiller machine as compared with conventional tillage moisture content (9.07%), bulk density (1.14 g/cm3) and penetration resistance (519 kPa). Seedling emergence rate index (11.26 %), number of tillers/m2(372) and grain yield (2984.58 kg/ha) were also found 1.1, 1.14 and 1.00 times more under zone disc tiller drill as compared with conventional tillage emergence rate index (10.18 %), number of tillers/m2(326) and grain yield (2975.55 kg/ha) respectively. The treatment vise fuel consumption was high under conventional tillage (T10) produced significantly greater fuel consumption (60.11 l/ha) while lowest fuel consumption was recorded under treatment T3 with disk coulter at speed three (11.83l/ha).

Received | January 15, 2018; Accepted | February 03, 2019; Published | April 20, 2019

*Correspondence | Muhammad Adnan Islam, Agricultural Engineering Institute, Pakistan Agricultural Research Council (PARC), Islamabad, Pakistan; Email: [email protected]

Citation | Islam, M.A., M. Iqbal, Z. Haq, M.M. Ali, H.S. Mahmood, S.A. Kalwar, L.A. Shahid, B.M.K. Niazi and M. Husain. 2019. Field performance evaluation of zone disk tiller machine for soil physical properties and its relative impact on wheat crop recovery in cotton stubble field. Pakistan Journal of Agricultural Research, 32(2): 343-352.

DOI | http://dx.doi.org/10.17582/journal.pjar/2019/32.2.343.352

Keywords | Zone disk tiller drill, Furrow opener, Emergence rate index, Penetration resistance, Yield

Introduction

In the ‘cotton–wheat’ cropping system of Pakistan, late planting of wheat is a serious problem due to often late harvesting of cotton crop. This leaves very inadequate time for land preparation for timely planting of wheat. No-tillage technologies decrease the mechanical and physical input for wheat cultivation after cotton. In the system of “cotton-wheat personal characteristics such as education, rental status, attitude to risk involved in using new technologies and contact with extension agents are the main factors influencing the adoption. Concerning the system cotton-wheat, resource endowments such as size of farm, access to a” no-till “drill, soils type and the area planted to cotton-wheat sequence with rental and contact with extension agents were dominant in explaining adoption. The speedy development of Pakistan agriculture is vital for the progress of country and to secure maximum crop production, the best use of the available land has to be made and the latest method of crop husbandry put into practice. There was a significant difference in yield, fuel consumption and other physical inputs with zero tillage than conventional tillage (Gray et al., 1996). Zero tillage technology is economically superior, and more grain yield was recorded under zero tillage as compared to conventional tillage (Nagarajanet al., 2002). The time of harvest and sowing of cotton and wheat overlap each other, which are not desirable and is a major constraint on crop productivity of wheat in cotton-wheat cropping system of Pakistan. Land preparation for wheat in cotton-wheat rotation is an energy consuming and a long process. The conventional method of preparing the seedbed creates difficulties in the timely preparation of seed bed of good seed wheat. This wheat planting delays of two to three weeks reduces crop yields and, consequently, the money spent on inputs is partially wasted (Aslam et al., 1991). The right time and the good seed bed preparation ensure maximum germination and cold weather reduces the risk of exposure to heat in the critical period of early grain filling.

Zone Disk tiller drill is a zero till technology designed and developed for rice-wheat cropping system but this experiment was tested in wheat-cotton cropping system because in cotton–wheat cropping systems of Pakistan, late planting of wheat is a recurrent problem due to often late harvesting of cotton crop. This leaves very inadequate time for land preparation for timely planting of wheat. This drill machine decreases the mechanical and physical input for wheat cultivation after cotton. Sarwar and Goheer (2007) stated that zero tillage technique for wheat cultivation is the most reasonable and attractive alternative for agricultural community. Less cost of production and high yield grain per hectare were observed on zero tillage farms as compared with conventional farms. The yield recorded under conventional method (3122.64 Kg/ha) was significantly lower than that zero tillage method (3409.98 Kg/ha).

Munir et al. (2012) tested the zone disk tiller drill machine by sowing wheat with three different furrow openers at three different speeds in rice stubble field. It was recorded that under disk-type furrow opener the seedling emergence rate index (ERI) and grain yield was higher than those under the hoe-type furrow opener and reverse-hoe-type furrow openers. In rice residue, disk type furrow opener at the intermediate tractor speed (4.75 km/h) was recommended over hoe type furrow opener and reverse hoe type furrow opener. As at this speed this machine creates good seed-soil contact and best soil conditions for water and nutrient availability to the crop.

Zero tillage technology was introduced in Pakistan in on farm water management (OFWM), Punjab and more than 4452 hectares have been sown by this technique in Punjab during 1999-2000 Rabi season (OFWM, 1999).

Zero tillage is basically direct drilling or placing of seed in the uncultivated soil through the mulch layer with the help of seed drill. Zone disc tiller machine developed in the department of Farm Machinery and Power is a new innovation for conservation tillage to produce row crops in Pakistan. Planting and disease insect control are similar to that in conventional tillage practices. Zone-till adds an additional option for fertilizer application. Residue management, soil conservation, erosion control and other environment friendly management options are all compatible with zone-tillage. This technique appears to be a major improvement in conservation agriculture. Zone disc tiller drill cuts and pulverize seed zone in front of furrow opener devices. The seed is placed at fixed depth in furrow opened by furrow openers. This machine performed satisfactorily in rice and cotton stubble field.

Materials and Methods

This study was conducted to evaluate the field performance of zone disk tiller drill in comparison with conventional method of wheat showing after harvesting cotton crop at Faisalabad during the rabbi season. Out of the total 2-ha area, half was sown by conventional method the other half was sown directly by zone disk tiller drill in the standing cotton stubbles. A Randomized complete block design (RCBD) was employed. Zone disk tiller drill was tested with three furrow openers; disk type furrow opener, reverse hoe type furrow opener and hoe type furrow openers. All of three furrow openers were operated at three different levels of speed (2.5km/h, 4km/h and 5.5km/h). It was imperative to study various soil, crop and machine parameters like soil moisture content, bulk density soil resistance to penetration, fuel consumption, emergence rate index, number of tillers/m2 and grain yield, etc.

Figure 1 and Figure 2 shows cotton stubble field before sowing and sowing wheat with ZDTD in cotton stubble field.

Conventional method is basically an old and traditional way of field preparation in which seedbed is prepared after several farm practices, such as crop residue burning, deep soil inversion by tilling to control weeds and to prepare the seed bed. Seedbed preparation was done with two field operations of rotavator, cultivator and planker and finally seeding wheat with rabbi drill.

A zone disk tiller drill consists of soil tilling unit and seed furrow opening and seed placement unit. The soil tilling unit had seven way disks (457 dia mm with 50 mm wave) with 228mm disk to disk distance. The tilling unit rotates at 242 RPM at rated speed of tractor PTO shaft (540 RPM). Two gear reduction devices have been employed to reduce 540 RPM of PTO to 240 RPM at disk shaft. Each disk prepares a narrow slit (50mm wide × 100mm deep) in front of each furrow opener. The seed/ fertilizer metering device, meter seed/fertilizer to place fertilizer deeper than seed in bulk. Each furrow opener is followed by a furrow covering device to cover seed by loose soil. The detail of the parameters studied is as follows.

Field layout

An area of 17082 square meters was divided into two equal size fields, and each field was further divided into three blocks. In one field land preparation and seedbed preparation was done with conventional method, and in the second field wheat was sown with Zone disc tiller drill (ZDTD) machine in standing cotton stubble without initial preparation of soil. Field plan layout had been prepared and shown in Figure 3. C1, C2 and C3= disk furrow opener, hoe furrow opener and reverse hoe furrow row opener. S1=2.5km/hr, S2=4km/hr and S3 =5.5km/hr. B1=block 1, B2=block 2 and B3= block 3. All the dimensions are in meter.

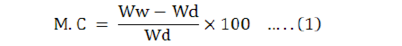

Soil moisture content and bulk density

Moisture content and bulk density were measured by taking soil sample, from depths of 0-5 cm and 5-10 cm both before and after sowing (at emergence). A soil core sampler with 5 cm diameter and 15 cm length was pressed and carefully executed for soil sampling (Ryan et al., 2001). Samples taken out from core sampler were saved in cans and transferred to laboratory for gravitational analysis. These samples were dried in an oven for 24 hours to measure moisture content of soil (Allison et al., 1954). Before sowing, core sampling was done from nine randomly selected spots in the field. After sowing three samples were taken from seedling rows of each subplot. Following equation were employed to determine soil moisture content and bulk density (Ryan et al., 2001).

Table 1: Treatments and their description.

| Treatment no | Treatment |

| T1 | C1S1 |

| T2 | C1S2 |

| T3 | C1S3 |

| T4 | C2S1 |

| T5 | C2S2 |

| T6 | C2S3 |

| T7 | C3S1 |

| T8 | C3S2 |

| T9 | C3S3 |

| T10 | CT |

| Blocks | B1 |

| B2 | |

| B3 |

C1, C2 and C3= disk furrow opener, hoe furrow opener and reverse hoe furrow opener; CT: Conventional tillage. S1=2.5km/hr, S2=4km/hr and S3 =5.5km/hr; B1=block 1, B2=block 2 and B3= block 3.

Where;

M.C = soil Moisture content in % Ww = wet weight of sample; g Wd= oven dried weight of soil sample; gB.D = bulk density of soil; g/cm3; V = volume of soil core; cm3 = Пd24 × L; d = core dia; cm and L = core length, cm.

Soil penetration resistances

The mechanical impedance is a phenomenon that affects seedling emergence in two distinct ways: impedance to the root system and impedance to seedling emergence (Choudhry, 1983). Soil resistance to cone penetration gives an indication of the force a seedling would exert for emergence. A cone penetrometer with cone area of 1.30 cm2 (12.83 mm diameter), 300 cone angle and 9.53 mm shaft diameter, was employed to measure cone penetration resistance (kPa) from 0-5 and 5-10 cm depth. The cone was pushed into soil at a uniform rate of approximately 30 mm/s (ASAE, 2003). Before planting, nine randomized spots were selected to determine soil strength. After emergence, three readings were taken from three randomly selected seedling rows of each subplot.

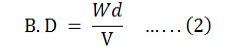

Germination count

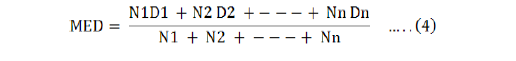

Seedling emergence rate index was calculated to know that how many plants were emerged every day in a unit area by counting number of plants emerged every day after emergence started. Rizvi (1991) stated that the rate of plant emergence might provide better understanding of the soil condition created by a particular tillage system than measurement of soil physical properties. In this study seed rate was 60 Kg/ha which was same for both zone disk tiller drill machine and Rabi drill (conventional method). Seedling emergence was recorded every day till it was ensured that no any seed was germinated after particular day. Emergence rate index (ERI) was calculated by using the following equation (Bilbro and Wanjura, 1982).

Where;

N1-----Nn = Increase in the number of emerged plant stems compared with the previous count; D1-----Dn = Number of days after planting.

Number of tillers per unit area (NT/m2)

The number of tillers per unit area is an important parameter in assessing the conduciveness of the micro environment of the seedbed. The numbers of plant per square meter were determined for three randomly selected locations in each treatment plot after 48 days of planting.

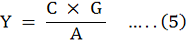

Grain yield

In order to calculate grain yield in each treatment avoiding border effects, wheat crop was harvested from an area of 1 m2 each from the randomly selected area under each treatment. Three sample areas were harvested in each treatment plot and yield comparison made using the following relationship.

Where;

Y = yield; kg/ha; G = grain weight; g, C = constant; 10; A = 1 m2 Area.

Fuel consumption

Fuel consumption was determined by filling the tractor fuel tank to its top at the start of field operation, and then refilling the tank to its capacity at the end of each operation. The quantity of fuel added later was considered the fuel consumed.

Statistical analyses

The data collected was statistically analyzed using PROC GLM (General Liner Model) procedure of SAS institute (SAS, 2002-03). The least significant difference LSD (α = 0.05) approach was used to compare the mean values of results for comparison of different treatments.

Results and Discussion

The regarding soil physical properties and crop parameters were statistically analyzed and discussed as following.

Table 2 showed mean values of moisture content, bulk density observed and penetration resistance before seedling were 16.64%, 1.55g/cm3 and 977 kPa. Mean value of moisture content at 5-10 cm depth (18.72%) was 1.28 times higher than that observed at 0-5 cm depth (14.56). Bulk density observed at 5-10 cm (1.69 g/cm3) was 1.19 times greater than that bulk density observed at 0-5 cm depth (1.42g/cm3). As the depth increased penetration also increased indicating the effect of greater bulk density at lower depth than that at upper depth which is a sign of soil compaction at lower depth. The penetration resistance observed at 5-10 cm depth (1114kPa) was 1.32 times greater than that observed at 0-5 cm depth (840 kPa).

Table 2: Analysis of variance of soil physical properties of field before sowing wheat with ZDTD.

| Depth (cm) | M.C (%) | BD (g/cm3) | PR ( kPa) |

| 0-5 |

14.56b |

1.42b |

840b |

| 5-10 |

18.72a |

1.69a |

1114a |

| Mean | 16.64 | 1.55 | 977 |

| LSD(0.05) | 0.9704 | 0.1619 | 139.58 |

Where; MC, BD and PR are moisture content; bulk density and penetration resistance respectively.

Table 3 also clearly indicated that the under conventional tillage mean value of moisture content, bulk density and penetration resistance were also significantly greater at 5-10 cm depth than those observed at 0-5 cm depth. The mean values for moisture content, bulk density and penetration reissuance at 5-10 cm depth were 12.69%, 1.40 g/cm2 and 776.8 kPa respectively. The reasons of high moisture content, bulk density could be the soil compaction and less evaporation at greater depth than those at the lower depth.

Table 3: Soil physical properties before sowing conventional tillage.

| Depth (cm) | M.C (%) |

BD (g/cm3) |

PR ( kPa) |

| 0-5 |

10.74b |

1.15 b |

536.8 b |

| 5-10 |

12.69a |

1.40 a |

776.8 a |

| Mean | 11.71 | 1.28 | 656.8 |

| LSD(0.05) | 2.11 | 0.55 | 78.2 |

Where; MC, BD and PR are moisture content; bulk density and penetration resistance respectively. Superscripts show vertical comparisons along respective columns. Same alphabetic superscripts. Shows NS: non-significant at α= 0.05.

Soil physical properties at seedling emergence

Moisture content: The Figure 4 also depicted that as tractor forward travel speed increased, the moisture content at 0-10 cm under furrow openers C1, C2 and C3 also increased because high speed caused less loosening effects on soil due to constant speed of wave disk (242 RPM). Disk furrow opener (C1) caused minimum soil disturbance, therefore, had significant greater moisture content at all speeds.

Bulk density: The effect of furrow openers type and forward travel speed were plotted in Figure 5. The Figure 5 depicted that as tractor forward speed increased, the bulk density at 0-10 cm depth, under furrow openers C1, C2 and C3 also increased because the low speed caused more loosening effect on the soil. This might be due to less time available for furrow opener at greater forward travel speed of the tractor to pulverize the soil due to constant speed of furrow opener. Furrow opener C1 resulting in high bulk density could be due to less soil inverting and disturbance effect than the other two C2 and C3 furrow openers.

Soil penetration resistance: The Figure 6 depicted that as tractor forward travel speed increased the penetration resistance under furrow openers C1, C2 and C3 also increased at and 0-10cm depth respectively, at seedling emergence because the low speed caused

more loosening effects on soil the non-parallel lines in both the plots showed insignificant effect of interaction C*S.

Effect of treatment combinations on moisture content bulk density and penetration resistance at seedling emergence: Statistically analyzed results of moisture content, bulk density and penetration resistance under different treatments have been presented in the Table 3. The Table 3 indicated that results were significant at 5% probability level treatment wise. The highest treatment toward the moisture content bulk density and penetration resistance in the study was treatment T3 which produced significantly greatest moisture content (15.72 %), (15.72 g/cm2) and (984.44 kPa). Comparative values of moisture content, bulk density and penetration resistance under zone disk tiller drill machine are shown in Table 4.

Crop parameters

Seed emergence rate index (ERI): Rizvi (1991) stated that the rate of plant emergence might provide better understanding of the soil condition created by a particular tillage system than measurement of soil physical properties. The seedling emergence count were daily recorded for three weeks after sowing wheat till it was ensured that no any seed will germinate. The data collected were statistically analyzed using PROC GLM (General Linear Model) procedures of the SAS system (2002-03). The effect of tractor forward speeds on ERI for crop planted by three furrow openers has been plotted in Figure 5. The Figure 7 showed that ERI was significantly greater with furrow opener C1 at all speeds than those crops planted by furrow openers C2 and C3 this could be due to good seed-soil contact and more nutrient availability to emerging seedling in furrow developed by disk furrow opener. Tractor forward travel speed S2 excelled in producing more ERI than those produced at S1 and S3 speed, indicating good seed-soil contact at speed S2.

Table 4: Effect of treatment combinations on soil penetration resistance at seedling emergence.

| Treatment no | Treatment combinations | Mean moisture content (%) | Mean bulk density(g/cm3) | Mean penetration resistance (kPa) |

| 1 | C1S1 |

13.84dc |

1.34dc |

818.16dc |

| 2 | C1S2 |

15.00abc |

1.45abc |

916.83ab |

| 3 | C1S3 |

15.72a |

1.57a |

984.44a |

| 4 | C2S1 |

13.32de |

1.30d |

776.16d |

| 5 | C2S2 |

14.50bdc |

1.38bdc |

888.10bc |

| 6 | C2S3 |

15.17ab |

1.50ab |

949.74ab |

| 7 | C3S1 |

12.27 e |

1.28d |

756.89 d |

| 8 | C3S2 |

13.65d |

1.38bdc |

871.69bc |

| 9 | C3S3 |

14.47bdc |

1.48ab |

914.76ab |

| 10 | CT |

9.07f |

1.13e |

591e |

| Mean | 13.70 | 1.38 | 846.78 | |

| LSD(0.05) | 1.20 | 91.31 |

Same alphabetic superscripts shows NS: non significant at α = 5%; C1, C2 and C3 = disk furrow opener, reverse hoe furrow opener and hoe furrow opener. CT= Conventional tillage; S1=2.5km/h, S2=4km/h and S3 =5.5km/h.

Number of tillers per unit area (NT/m2): The numbers of plant per square meter were conducted for three randomly selected locations in each treatment plot. The recorded data were statistically analyzed. The effect of tractor forward speeds on NT/m2 for crop planted by three furrow openers has been plotted in Figure 8. The Figure 8 showed that NT/m2were significantly greater with furrow opener C1 at all speeds than those crops planted by furrow openers C2 and C3. Tractor forward travel speed S2 excelled in producing more NT/m2 than those produced at S1 and S3 speed.

Grain yield: The grain yield per unit area has a direct dependence on the soil physical properties produced by machines and climatic conditions. The crop yield data collected under three furrow openers and three forward speeds were statistically analyzed. The effect of tractor forward speeds on grain yield for crop planted by three furrow openers has been plotted in Figure 9. The Figure 9 showed that grain yield was significantly greater with furrow opener C1 at all speeds than those crops planted by C2 and C3. Tractor forward travel speed S2 excelled in producing more yield than those produced at S1 and S3 speed.

Effect of treatment combination on grain yield: Statistically analyzed results of emergence rate index, no of tillers per square meter and grain yield have been presented in the Table 5. Table 5 showed the effect of treatments combination on emergence rate index, no of tillers per square meter and grain yield. The Table 5 indicated that Grain yield results were significant at 5% probability level treatment wise. The best treatment toward the emergence rate index, no of tillers per square meter and grain yield in the study was T2 which produced significantly greatest ERI (12.16 %), NT/m2 (458) and grain yield, (3177 kg/ha).

Table 5: Effect of treatment combination on Emergence rate index, No of tillers per square meter and Grain yield.

| Treatment no | Treatments | Seed emergence rate index (ERI) | Number of tillers per unit area (NT/m2) | Mean grain yield (kg/ha) |

| 1 | C1S1 |

11.73ab |

419b |

3039.33ab |

| 2 | C1S2 |

12.16a |

458a |

3177.00 a |

| 3 | C1S3 |

11.23abc |

392cd |

2954.67bdc |

| 4 | C2S1 |

11.07abc |

374d |

2801.00d |

| 5 | C2S2 |

10.77abc |

404bc |

3066.00ab |

| 6 | C2S3 |

10.70abc |

348 e |

2909.33bcd |

| 7 | C3S1 |

10.70abc |

314gf |

2910.67bcd |

| 8 | C3S2 |

9.86c |

347 e |

2999.33abc |

| 9 | C3S3 |

9.73 c |

293g |

2847.33cd |

| 10 | CT |

10.16bc |

326ef |

2975.67bcd |

| Mean | 10.81 | 368 | 2968.03 | |

| LSD(0.05) | 1.66 | 26.30 | 178.42 |

Same alphabetic superscripts shows NS: non significant at α = 5%; C1, C2 and C3= disk furrow opener, reverse hoe furrow opener and hoe furrow opener; CT= Conventional tillage; S1=2.5km/h, S2=4km/h and S3 =5.5km/h

Fuel consumption: Zero tillage is claimed to be energy saving as compared to conventional tillage that needs to be investigated under specific soil and

climatic conditions. In order to compare the three coulters C1, C2 and C3 at three different speeds S1, S2 and S3 measurements of fuel consumption were made. The fuel consumption has a direct dependence on the farm operations involved in different sowing techniques. The data of fuel consumption were recorded and statistically analyzed using PROC GLM (General Linear Model) procedures of the (SAS, 2002-03).

The Figure 10 showed that fuel consumption was significantly greater with C3 (16.22 l/ha) at all speeds than those crops planted by C1 (13.00l/ha) and C2 (15.87 l/ha). Tractor forward travel speed S1 consumed more fuel as compare to other two speeds S2 and S3.

Table of treatments for fuel consumption (l/ha): Statistically analyzed results of fuel consumption have been presented in the Table 6. The Table 6 indicated that fuel consumption results were significant at 5% probability level treatment wise. The treatment vise fuel consumption was high under treatment T10 produced significantly greater fuel consumption (60.11 l/ha) while lowest fuel consumption was recorded under treatment T3 with disk coulter at speed three (11.83l/ha).

Table 6: Effect of treatment combinations on fuel consumption.

| Treatment no | Treatments | Mean (l/ha) |

| 1 | C1S1 |

14f |

| 2 | C1S2 |

13.17f |

| 3 | C1S3 |

11.83h |

| 4 | C2S1 |

16.57 bc |

| 5 | C2S2 |

15.90cd |

| 6 | C2S3 |

15.15e |

| 7 | C3S1 |

17b |

| 8 | C3S2 |

16.33bc |

| 9 | C3S3 |

15.33 de |

| 10 | CT |

60.11a |

| Mean | 19.53 | |

| LSD | 0.744 |

Same alphabetic superscripts shows NS: non significant at α = 5%; C1, C2 and C3= disk furrow opener, hoe furrow opener and reverse hoe foe row opener; CT= Conventional tillage; S1=2.5km/hr, S2=4km/hr and S3 =5.5km/hr.

Conclusion and Recommendations

This study was conducted to evaluate and compare field performance evaluation of zone disk tiller machine as compare to conventional tillage practices in cotton stubble field. Zone disk tiller machine is basically a resource conservation zero tillage technology for wheat sown in rice and cotton stubble field. Further in this study, impacts of zone disc tiller drill and conventional sowing method were evaluated and compared on soil physical properties and wheat crop recovery in cotton stubble field. Zone disc tiller drill was tested with three different coulters at three different speeds. In this study, moisture content (15.72 %), bulk density (1.41 g/cm3) and penetration resistance (875.21 kPa) were found 1.73, 1.23 and 1.48 times more under zone disc tiller machine as compared with conventional tillage moisture content (9.07%), bulk density (1.14 g/cm3) and penetration resistance (519 kPa). Seedling emergence rate index (11.26 %), number of tillers/m2 (372) and grain yield (2984.58 kg/ha) were also found 1.1, 1.14 and 1.00 times more under zone disc tiller drill as compared with conventional tillage emergence rate index (10.18 %), number of tillers/m2 (326) and grain yield (2975.55 kg/ha) respectively. The treatment vise fuel consumption was high under conventional tillage (T10) produced significantly greater fuel consumption (60.11 l/ha) while lowest fuel consumption was recorded under treatment T3 with disk coulter at speed three (11.83l/ha). In cotton stubble field residue, disk type furrow opener (C1) at the intermediate tractor speed (4 km/h) was recommended over hoe type furrow opener and reverse hoe type furrow opener. As at this speed this machine fuel consumption was less and creates good seed-soil contact and best soil conditions for water and nutrient availability to the crop. Ultimately there will be good crop stand establishment and maximum crop yield as compared to conventional tillage.

Author’s Contribution

Muhammad Adnan Islam: conceived the idea, Overall management of the article and did SAS analysis.

Muhammad Iqbal: conceived the idea.

Zia-ul-Haq: Methodology , and wrote abstract.

Muhammad Mohsin Ali: Data collection.

Hafiz Sultan Mahmood: Technical Input at every step.

Shabbir Ahmed Kalwar: Conclusion.

Liaqat Ali Shahid: Data entry and analysis.

Badar Munir Khan Niazi: Result and discussion.

Muzammil Husain: Introduction.

References

Allison, L.E., L. Bernstein, A. Bower, J.W. Brown, M. Firemen, J.T. Hattcher, H.E. Hayward, G.A. Pearson, R.C. Reeve, L.A. Richards and L.V. Wilcon. 1954. Agriculture handbook no-60, US Dep. Agric. USA.

ASAE. 2003. ASAE standards (ASAE S313.2 DEC 1974). Standards engineering practices data. Adopted Publ. Am. Soc. Agric. Eng.

Aslam, M., Ahmad, N.I. Hashmi, M.Q. Chata and M.V. Veen. 1991. Zero tillage wheat plot production program for the Punjab rice-wheat system. Pak. Agric. Res. Counc. Islamabad. ISBN. 969-409-084-9.

Bilbro, J.D. and D.F, Wanjura. 1982. Soil crusts and cotton emergence relationships. Trans. ASAE, 25(6): 1484-1487.

Chaudhry, A.D. 1983. Potential of direct drilling in developing countries. ANA. 14(4): 15-19.

Gray, R.S., J.S. Taylor and W.J. Brown. 1996. Economic factor contribution to the adoption of reduced tillage technology in the central Saskatchewan. Can. J. Plant Sci. 76 (1): 661-668. https://doi.org/10.4141/cjps96-116

Nagarajan, S., A. Singh, R. Sigh and S. Singh. 2002. Impact evaluation of zero tillage in wheat through farmer’s participatory mode. Paper for international workshop on herbicide resistance management and zero tillage in rice wheat cropping system, March, 4-6 2002. Dep. Agron. CSS Haryana Agric. Univ. Hisar-125004, India.

Munir, M.A., M. Iqbal and S. Miran 2012. Evaluation of three seed furrow openers mounted on a zone disk tiller drill for residue management, soil physical properties and crop parameters. Pak. J. Agric. Sci. Vol. 49(3): 349-355; 2012.

OFWM. 1999. Zero tillage for enhancing wheat productivity, Recommendation for 1997-2000. Dir. Gen. Agric. Water Manage. Punjab.

Rizvi, H.A., S.J. Marley, T.S. Colvin and D.C. Erbach. 1991. Tillage index trails at different agro-ecological zones. Paper presented at the 1991 international summer meeting of the ASAE held at Albuquerque Conv. Center Albuquerque, New Mexico, June 23-15. Paper No. 911004.

Ryan, J., G. Estefan and A. Rashid. 2001. Soil and plant analysis laboratory manual. ICARDA. Aleppo, Syria.

SAS. 2002-03. SAS/ STAT user’s guide. Version 9.1 SAS inst. Inc. Cary, NC.

Sarwar, M.N. and M.A. Goheer. 2007. Adoption and impact of zero tillage technology for wheat in rice-wheat system-water and cost saving technology. A case study from Pakistan (Punjab). Paper presented Int. Forum Water Environ. Governance in Asia, March 14–15, 2007, Bangkok, Thailand.

To share on other social networks, click on any share button. What are these?