Response Surface Modelling and Analysis for Ball Milling of Coriander Seeds

Response Surface Modelling and Analysis for Ball Milling of Coriander Seeds

Sivamani Selvaraju, Naveen Prasad Balakrishna Pillai Sankari*, Halima Khalid Mohammed Al-Shukaili, Mohammed Ahmed Al-Mashikhi and Salim Said Salim Shaaban Bait Jamil

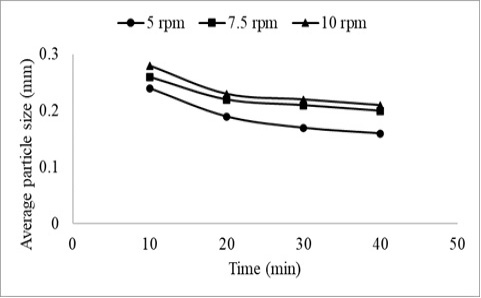

Milling time effect on particle average size at different rotational speeds (5, 7.5 and 10 rpm) for 25 g feed.

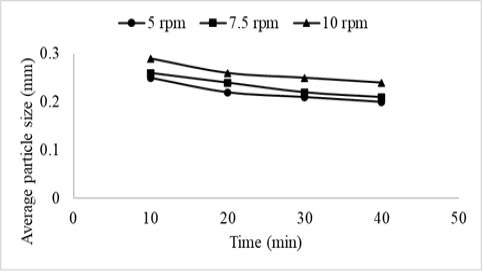

Milling time effect on particle average size of coriander seeds at various rotational speed (5, 7.5 and 10 rpm) for 50 g feed.

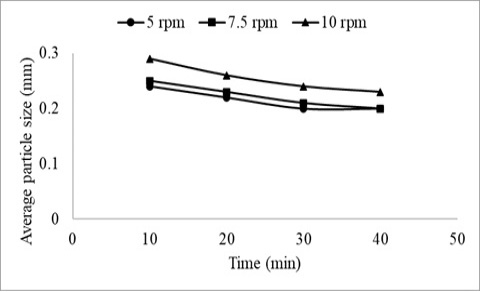

Milling time effect on particle average size at different rotational speeds (5, 7.5 and 10 rpm) for 75 g feed.

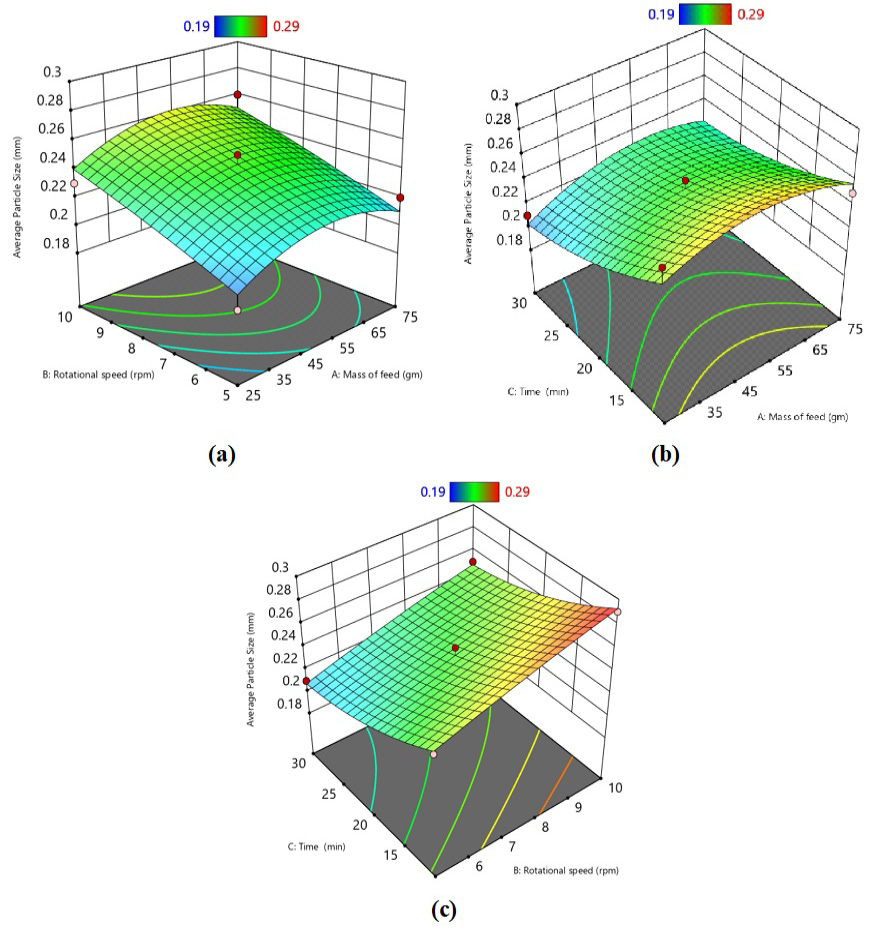

3-D plots showing interactive effect between (a) mass of feed and rotational speed of milling, (b) mass of feed and time of milling, and (c) rotational speed and time of milling on average particle size of C. sativa seeds after ball milling.