Effect of Beef Fat Replacement with Linseed Oil Emulsions on Physicochemical and Sensory Properties of Beef Patties

Effect of Beef Fat Replacement with Linseed Oil Emulsions on Physicochemical and Sensory Properties of Beef Patties

Ayesha Anwar, Sadia Aslam and Nauman Khalid*

Department of Food Science and Technology, School of Food and Agricultural Sciences, University of Management and Technology, Lahore 54000 Pakistan

Ayesha Anwar and Sadia Aslam have contributed equally to this article.

ABSTRACT

The aim of this study was to replace beef fat with linseed oil emulsions in beef patties to measure its impact on physicochemical and sensory properties. The varying concentrations of beef fat was replaced with 5 to 15% linseed oil-based emulsions. The chemical composition of the patties was affected by the inclusion of the linseed oil emulsion in patties. The cooked and uncooked patties prepared with the 10% and 15% linseed emulsion showed highest moisture and ash content while patties with 20% beef showed highest fat and protein content. There was a significant difference between the pH values of cooked and uncooked patties from different treatments. Increased lipid oxidation content was observed in cooked and uncooked patties containing different concentrations of emulsions, together with non-significant difference in values of water holding capacity and cooking yield among different treatments. A slightly higher scores were obtained for sensory parameters of patties containing linseed oil emulsions.

Article Information

Received 15 February 2022

Revised 20 March 2022

Accepted 08 April 2022

Available online 16 June 2022

(early access)

Published 13 June 2023

Authors’ Contribution

AA and SA planned the research. AA conducted all the experiments and analyzed the data. NK and SA supervised the research and wrote the manuscript.

Key words

Beef fat, Patties, Fat replacer, Linseed oil emulsion, PUFAs

DOI: https://dx.doi.org/10.17582/journal.pjz/20220215060250

* Corresponding author: [email protected]

0030-9923/2023/0004-1715 $ 9.00/0

Copyright 2023 by the authors. Licensee Zoological Society of Pakistan.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

Beef is an abundantly consumed meat worldwide. Beef has high protein quantity and an abundance of other essential fatty acids, minerals, and vitamins (Pighin et al., 2016). Beef as a red meat has several important dietary factors, such as fat, high protein content, bioactive substances, antioxidants, trace elements and vitamins (Ahmad et al., 2018; Li, 2017). Beef products are commonly used as steaks, fillets, sausages, ham, meatballs, patties, pâté and spreads. Low levels of polyunsaturated fatty acids (PUFAs) or insufficient saturated fatty acids (SFAs)/ PUFAs ratio of beef can be unhealthy.

Frequent intake of saturated fats increases low-density lipoprotein leading to cardio vascular diseases, obesity (Briggs et al., 2017; Ruiz-Núñez et al., 2016) and different malignant growths (Hammad et al., 2016). Less than 10% of SFAs daily intake in diet is recommended value by German Society of Nutrition. With the growth of meat consumption with SFAs there is a need to modify dietary patterns. It is reported that use of PUFAs as substitute to SFAs, reduces risk of coronary heart diseases. PUFAs are essential fatty acids that are known for several beneficial effects such as prevention against inflammation and metabolic syndromes (Bentsen, 2017). Improving the fatty acid profile can have optimistic outcome regarding human health.

As the demand for low fat and less cholesterol increased, it has become essential to seek sustainable dietary sources for lipid reformulation, meeting the demand of n-3 fatty acids. Previous studies have informed that there are various oils used to modify the fatty acid profile of meat products such as olive oil (Bolumar et al., 2015; Nieto and Lorenzo, 2021; Serdaroğlu et al., 2017), sesame oil (Zhuang et al., 2016), canola oil (Barbut et al., 2016; Selani et al., 2016) and chia seed oil (Heck et al., 2019; Pintado and Cofrades, 2020).

We have selected linseed oil as it has highest concentration of α-linolenic acid in comparison to the other seed oils approximately 50-55%, that indicates satisfactory stability of polyunsaturated, monounsaturated and saturated fatty acids. Linseed oil contains about 36-40% oil and high amount PUFAs, which has favorable functions in food industry that are beneficial for health. Linseed is important seed agriculturally in worldwide. It consists of many functional ingredients. In lipids -linoleic is major component along with oleic, stearic, palmitic and linoleic acid. It has a positive effect on carcinogenic agents and lowers the low-density lipoproteins. The amino acids are antifungal and demonstrated antioxidant functions (Dzuvor et al., 2018). It has been used as fat replacer in meat products (Alejandre et al., 2016; Câmara and Pollonio, 2015; Lima et al., 2021; Nacak et al., 2021; Poyato et al., 2015). Linseed oil emulsions are successfully used as a pork fat replacer in a study, resulting in positive effects on nutritional quality of meat and no negative impact on sensory attributes as well (Alejandre et al., 2016). Another study by Franco et al. (2020) indicated that the high fat content in pork back fat was replaced with different proportions of two linseed oleogels in smoked sausages to improve its nutritional quality. The effects of fat reduction and addition of canola oil or pre-emulsified canola oil on cooking loss, texture, and color of comminuted meat products have been demonstrated by Youssef and Barbut (2011). Cooking loss and hardness were increased when fat was reduced from 25% to 10%. Canola oil or pre-emulsified treatments had a favorable influence on yield and textural parameters restoration. The use of canola oil or pre-emulsified oil reduced redness of meat products significantly (Youssef and Barbut, 2011). The use of peanut and linseed oil based gelled emulsions in fermented sausages have demonstrated the improved color, sensory score and reduced purge loss and lipid oxidation (Öztürk-Kerimoğlu et al., 2021b). In another study, replacement of animal fat with olive oil emulsion in meat batters significantly lowered the hardness and fluid loss during storage while gumminess and cohesiveness were increased (Öztürk-Kerimoğlu et al., 2021a).

The goal of this study was to develop and characterize the linseed O/W emulsions, to replace beef fat in beef patties. The principal objective of the current study was to provide a different approach for consumption, aimed at meeting the nutritional requirements without affecting their sensory and technological properties and to determine the effect of beef fat content and linseed oil on the emulsion stability, color, pH, texture profile and sensory features of beef patties.

Materials and Methods

Raw materials

Ground beef was purchased from local meat shop, washed and stored at 4°C. Linseed oil was obtained from local shop and used as oil phase for emulsion formation. Distilled water was used as continuous phase and decaglycerol monolaurate (ML-750) was used as emulsifier and kindly provided by Sakamoto Yakuhin Kogyo Co., Ltd (Osaka, Japan). Rest of the chemicals were of analytical grade and used as such in evaluation of samples.

Oil-in-water emulsion preparation

For preparation of O/W emulsions, the continuous phase was prepared by dissolving 1% (w/w) ML-750 and 0.5% (w/w) carrageenan in distilled water at 40°C and stirred for 30 min on a hot plate to form a flowable gel like solution (Scilogex, MS-H280-Pro, CT, USA). After formation of gel-like solution 90 mL of solution was separated for formulation of O/W emulsions. For oil phase, 10% (w/w) linseed oil was added dropwise in the aqueous phase. This pre-mix was homogenized at 7000 rpm for 5 min with rotor-stater homogenizer (HG-15D, Daihan Scientific Co Ltd, Korea). After homogenizing the prepared emulsion was stored at 4oC for 24 h until the time of processing of the beef patties.

Experimental design and preparation of beef patties

Four treatments of beef patties were formulated with different proportion of beef fat and linseed oil emulsion. Other ingredients such as salt, black pepper, onion and chopped garlic were also added in all treatments. Compositional analyses, peroxide value, physiochemical analyses, cooking yield and water holding capacity tests of uncooked and cooked patties were performed in triplicate.

Characterization of the emulsions

Emulsion stability (ES)

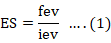

Emulsion stability was measured using centrifugation method outlined by Hosseini et al. (2015). 5 mL of emulsion was taken in falcon tube and placed in centrifuge at 3500 rpm at 3oC for 15 min. The emulsion stability was calculated as:

Where fev is the final emulsion volume, and iev is initial emulsion volume.

Creaming index of emulsions

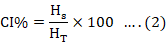

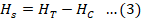

The creaming stability (CI) of emulsion was evaluated visually after 24 h storage at 4oC using the procedure outlined by Carpenter and Saharan (2017). The CI of 100% denotes that the emulsion is stable i.e., no separation occurs. The CI was calculated using the following equation:

Here, HS represents the height of stable phase, Hc represents the height of cream layer at the top of emulsion and HT represents the total height of emulsion or solution.

Preparation of beef patties

All visible fat and connective tissues were removed manually from the ground beef. For processing, ground beef 77.5%, beef fat and linseed oil emulsion were blended and mixed with the remaining ingredients including salt 0.5%, black pepper 0.5%, onion 1%, chopped garlic 0.5% until complete homogenization. The obtained meat emulsion was molded using molder to form patties (Paula et al., 2019).

First four treatments included only beef fat, To (20% fat), T1 (15% fat), T2 (10% fat) and T3 (5% fat), other treatments include T4 (beef fat 15% and 5% linseed oil emulsion), T5 (10% beef fat and 10% linseed oil emulsion) and T6 (5% beef fat and 15% linseed oil emulsion).

Compositional analyses

The compositional analyses were performed to determine the fat, protein, moisture and ash content of patties by the standard methods of AOAC (2012).

Physicochemical evaluation

The physicochemical tests of beef patties were performed by finding color, pH, cooking yield and loss, water holding capacity and oxidation stability.

Color determination

Color parameters of cooked and uncooked patties were measured using colorimeter. The homogenized beef batter and cooked patty samples were placed on a plate and covered with a polyethylene film to obtain a bubble free surface. Color parameters were acquired using the CIE L*, a*, b* system. L*, a* and b* parameters specify lightness, redness and yellowness, respectively (Alejandre et al., 2016).

pH analysis

The pH was measured of uncooked and cooked beef patties using a digital pH-meter (Combo Gro’check pH meter, Hanna, Romania) equipped with a penetration glass probe (Barbut et al., 2016). 1 g sample was weighed and 9mL of distilled water was added and mixed. The pH was measured by calibrating the glass probe with buffer to set at neutral pH 7 before inserting in the sample.

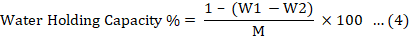

Water holding capacity (WHC)

The ability of the uncooked product to retain moisture was determined in triplicate according to the method described by Serdaroğlu et al. (2018b) with slight modifications. 1 g of sample was initially weighed (W1) in a petri plate. After this, the samples were wrapped in filtered paper, placed in Eppendorf tube and centrifuged at 1,600 rpm for 20 min and weighed again (W2). WHC was calculated from the equation below:

M indicates total moisture content of the sample.

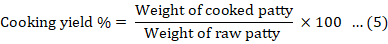

Cooking yield

The cooking yield was determined by placing ground beef on a petri dish, wrapping it in aluminum foil. Then it was cooked in polyethylene zipper bags by immersion in water bath at 80°C for 30 min. After removing cooked meat from bag, it was be cooled down at room temperature and weighed. Cooking yield was stated as the percentage of weight lost during heating (Utama et al., 2018), determined by following formula:

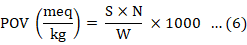

Peroxide value (POV)

The peroxide value (primary oxidation) was determined by using the method of Rahman et al. (2015). First 5g of sample was taken and heated in water bath for 3 min at 80oC to melt the fat. After heating, 30mL of Acetic acid and chloroform in a 3:2 was added in the sample and filtered after few min. Then 1mL of saturated potassium iodide was added and the sample was shaken vigorously for 1 min. Distilled water was added in the sample, which made the solution turn off-white. 0.5 mL starch was added that turned the solution purple. The sample was titrated with 0.01N Sodium thiosulphate and POV was calculated using the equation:

Where S= Volume of sodium thiosulfate solution used for titration in mL; N= Normality of the sodium thiosulfate solution; W= Sample weight in grams.

Sensory analysis

A panel of professionals evaluated different treatments of beef patties in sensory evaluation laboratory. The panel tested the sensory attributes of patties like appearance, flavor, taste, chewiness and color using a hedonic scale (Peryam and Pilgrim, 1957) scoring from 0 up to 9.

Statistical analysis

Using the SPSS for Windows statistical package tool, one-way analysis of variance (ANOVA) was utilized to determine the statistical significance of the influence of beef patties compositions (IBM, version 25.0). CRD (completely randomized design) was used to examine the data. The Tukey’s test was applied to compare mean formulation values and significant differences, whereas the paired t-test was utilized to determine whether there was a significant difference between uncooked and cooked treatments.

Results and Discussion

Emulsion stability and creaming index

The O/W emulsions were prepared with rotor-stater homogenizer and stored at 4oC for 24 h. The volume mean diameter of different O/W emulsions ranged between 0.5 to 3 m that indicate polydispersity among different samples. The observed polydispersity was mainly due to low rotation speed set during homogenization and the processing without any high-pressure involvement. The mild conditions were set to avoid any oxidational loss of linseed oil during patties formulation and to give enough chance of stability during frying of patties.

The centrifuge test results indicate 89.6% stability after accelerated separation. Creaming index of the emulsions was observed at 25oC and 4oC. Higher CI was observed at 25oC as compared to the emulsion stored at 4oC. Emulsion stored at 4oC possessed higher stability as compared to the emulsion stored at 25oC. The stability of O/W emulsion was lower at 25oC due to higher polydispersity at this temperature. The similar results in terms of emulsion stability and CI of olive oil emulsion were obtained by Serdaroğlu et al. (2017).

Compositional analysis

Fat

Reduction of fat content in beef patties is main objective of this study, addition of vegetable oils in meat products to substitute animal fat could be beneficial for consumer wellbeing as these oils are cholesterol-free and contain a higher ratio of unsaturated to saturated fatty acids. Figure 1A demonstrates a significant (p= 0.00) difference in fat content of both uncooked and cooked treatments. The difference of formulation in all treatments have significant impact on fat values of patties. The highest fat content was observed in control treatment To (18.5%). Lowest fat content was observed in cooked T3 (4.2%) with 5% beef fat and in T6 (4.5%) in which 75% fat was replaced with linseed oil emulsion. The fat content in all treatments was affected by formulation modification according to our expectations.

For cooked beef patties significant difference in fat content of all treatments was observed. A reduction in fat content from To (14.1%) to T6 (4.5%) was observed. T1 and T4 contained beef fat 15% equally. Fat content of T1 reduced significantly after cooking, while fat content of T4 slightly reduced after cooking. Slight reduction in fat content of T4 might be attributed to the fat binding ability of the linseed oil emulsions. Paired t-test indicated no significant difference (p>0.05) in fat content of cooked and uncooked patties from all treatments except T6. These observations were a result of replacement of beef fat by linseed oil emulsion. In a recent study by Carvalho Barros et al. (2020), tiger nut (Cyperus esculentus L.) oil emulsion was used as fat replacer in beef patties and noticed a gradual decrease in fat content of patties with the inclusion of emulsion in beef patties. The results regarding fat content obtained in current study were in same trend of above-mentioned study. In another study by Heck et al. (2019) hydrogel emulsion from chia and linseed oil was utilized for preparation of low-fat beef burgers. A similar trend in fat reduction was obtained. The fat replacement strategy is also applied in other meat, for example a study by Serdaroğlu et al. (2017) used gelled emulsion of olive oil to enhance the quality parameters of chicken patties. Reduction of fat was observed in this study as the quantity of emulsion was increased in patties in both uncooked and cooked treatments.

Protein

Red meat is a rich source of protein, sample beef contains about 16.9% of protein and provides all the essential amino acids required by human body. Figure 1B indicates non-significant (p= 0.36) difference in protein content of uncooked and cooked treatments of beef patties. In case of uncooked treatments highest values of protein contents was observed in T3 (15.8%) and To (15.3%) due to high protein percentage in beef. While there was slight decrease of protein content in treatments containing different proportions of linseed emulsion and beef fat (T4 (14.2%), T5 (14.8%) and T6 (14.4%)) as linseed oil has a less amount of protein content. In cooked treatments the protein content in cooked beef was higher than uncooked due to moisture and fat loss during cooking process. There was no significant difference among the protein content of treatments ranging from To (18%) to T6 (16.4%).

The cooked treatments had more protein content than the uncooked ones due to loss of bound moisture held by protein molecules during cooking. According to paired t-test there was a not a significant difference between protein content of uncooked (15.3%) and cooked (17.1%) treatments like To, T1, T3, T4 and T5. While there was a significance difference between protein content of uncooked (14.3%) and cooked (16.9%) treatment T2 and protein content of uncooked (14.4%) and cooked (16.4%) patties of T6. In a study by Franco et al. (2020) linseed oil oleogels was evaluated in partially replacement of pork backfat in sausages. This study observed that the sausage with high amount of linseed oil demonstrated a non-significant reduction in protein content. Similarly, another study by Heck et al. (2019) observed a reduction in protein content as the amount of chia and linseed oil emulsion was increased in beef patties replacing pork back fat. The results of current study were in close corroboration to these studies.

Moisture

Figure 1C indicates the moisture content in uncooked and cooked beef patties. The difference in uncooked beef patties was significant among all treatments (p=0.036). The control To has the lowest value 61.3% while T6 has highest moisture content (64.6%) in comparison to other treatments due to presence of high emulsion concentration.

In cooked samples non-significant (p=0.394) differences were found in moisture content of beef patties among treatments. Figure 1C indicates that moisture content was comparatively low in To (60.1%) and gradually increased in other treatments up to T6 (62.8%). The replacement of 15%, 10% and 5% beef fat with linseed oil emulsions caused an increase in moisture of both uncooked and cooked treatments due to the presence of water in emulsion. However, cooking process caused the reduction in moisture content due to moisture loss during cooking. According to paired t-test there was a non-significant (p>0.05) difference between moisture content of uncooked and cooked patties of To, T1, T2, T3, T4, and T6. While there was significance difference (p<0.05) between uncooked (64.7%) and cooked (61.7%) patties of T5. In a study by Serdaroğlu et al. (2017), addition of gelled olive oil emulsion was studied in chicken patties and as the content of emulsion increased the moisture content also increased, the obtained results were in agreement with the findings of current study. In another study by Serdaroğlu et al. (2018) pre-emulsified pumpkin seed oil (PO) was used as beef fat replacement in chicken meat emulsion and moisture content ranged from control (62.05%) to 50% PO (65.9%). Similarly, the outcome of our study was in accordance with another study (Câmara and Pollonio, 2015). In this study pre-emulsified linseed oil was utilized in bologna sausages to enhance the technological and sensory properties.

Ash

Figure 1D represents the ash content in uncooked and cooked beef patties. The samples showed significant difference in ash content among all cooked (p=0.014) and non-significant difference among uncooked (p=0.290) treatments. Ash content increased from (To) 1.86% to (T6) 2.20% in uncooked patties. The increase in ash content in treatments containing emulsions such as T4 (2.14%), T5 (2.16%) and T6 (2.21%) was due to mineral content of linseed oil. In cooked treatments there was a significant change in ash content among the treatments ranging from To (2.0%) to T6 (2.5%). According to paired t-test there was a non-significant (p>0.05) difference between ash content of uncooked and cooked patties of T1, T2, T3, T4, and T6. While there was a significant difference (p<0.05) between uncooked and cooked patties of To and T5. Alejandre et al. (2016) showed no significant (p>0.05) difference in dry fermented sausages when linseed oil gelled emulsion was added to replace the fat content of patties.

Physicochemical analysis

According to meat scientists, factors such as ultimate pH, color and water-holding capacity are the main technical attributes that drive consumer purchasing decisions.

Color

Color is essential parameter in customer acceptance, it determines the values of L* (lightness), a* (redness) and b* (yellowness) of beef patties. The effect of fat replacement on color values of beef patties in uncooked and cooked treatments is shown in Tables I and II, respectively. The uncooked treatments showed significant difference (p =0.006) in CIE L* values, where T6 (50.8) exhibited highest value due to highest emulsion content. White color of linseed oil emulsion caused the lightness (L*) of the patties containing emulsion. To, T1 and T2 showed low value of CIE L* 43.6, 43.7 and 42.5, respectively. The effect of fat replacement on a* values of patties in different treatments was non-significant (p=0.17) in uncooked patties but T6, T5 and T4 showed low values of a* 10.4, 11.8 and 10.6, respectively, while To showed highest a* value of 13.3 due to absence of emulsion and abundance of myoglobin in beef muscle. Similarly, treatments show significant (p=0.006) effect on the b* values. T6 (15.5) and T5 (16.73) showed high b* values due to yellow color of linseed oil emulsion.

According to paired t-test there was a non-significant (p>0.05) difference between L* values of uncooked and cooked patties of T1, T2, T3 and T6. There was significant difference (p<0.05) in L* values between uncooked and cooked patties of To, T4, T5, and T6. Paired t-test indicates that there was a non-significant (p>0.05) difference between a* values of uncooked and cooked patties of T4 and T6 while there was a significance difference (p<0.05) between a* values of uncooked and cooked patties of To, T1, T2, T3 and T5. According to paired t-test of there was non-significant (p>0.05) difference between b* of uncooked and cooked patties of T0, T1, T3, T4 and T5. There was significance difference (p<0.05) in b* values between uncooked and cooked patties from T2 and T6. In a study by Câmara and Pollonio (2015) pre-emulsified linseed oil was used to reduce animal fat in bologna sausages, the lightness (L*) of sausages with emulsion was higher due to highest emulsion content and white color of linseed oil. The obtained results were in accordance with the results of current study.

pH

pH is the measurement of acidity in food. The acid effect the flavor of food by releasing hydrogen ions. In case of fresh beef sample pH was 6.2. Glycogen level has an inverse relation with pH in muscle. The stress of any type on meat can lower the level of glycogen affecting the lactic acid and as a result increase in pH level. Table I indicates the pH values of uncooked and cookedbeef patties, respectively, there was a significant (p=0.00) difference in pH values of different treatments. For uncooked treatments the pH ranged from 6.0 to 5.96, there was a significant difference (p=0.003) among the treatments. The highest value was observed in control treatment, as beef showed high pH than linseed oil.

Table I. Physiochemical analysis of uncooked and cooked beef patties (Color, pH, and Peroxide value).

|

Treatments* |

Color |

pH |

Peroxide value (meq/kg) |

||

|

L* |

a* |

b* |

|||

|

Uncooked beef patties |

|||||

|

T0 |

43.60a ±4.10 |

13.36±2.57 |

16.46a±0.80 |

6.04b± 0.03 |

0.14 ± 0.32 |

|

T1 |

43.73a±2.89 |

12.20±1.12 |

15.20a±0.95 |

6.01b± 0.02 |

0.11 ± 0.10 |

|

T2 |

42.53a±3.21 |

12.81±1.55 |

16.20ab±0.70 |

6.06b± 0.01 |

0.113 ± 0.22 |

|

T3 |

42.66a±1.00 |

11.56±0.61 |

15.63ab±0.41 |

5.99b± 0.04 |

0.108± 0.20 |

|

T4 |

44.06ab±1.60 |

10.63±0.83 |

15.53ab±0.70 |

5.80a± 0.02 |

0.159± 0.40 |

|

T5 |

47.90ab±1.38 |

11.83±0.64 |

16.73b ±0.47 |

5.81a± 0.05 |

0.153 ± 0.30 |

|

T6 |

50.86b±1.25 |

10.46±1.20 |

15.56ab±1.48 |

5.98b± 0.09 |

0.159 ± 0.10 |

|

p-values |

0.006 |

0.17 |

0.006 |

0.00 |

0.507 |

|

SEM |

0.77 |

0.33 |

0.34 |

0.023 |

0.13 |

|

Cooked beef patties |

|||||

|

T0 |

35.13a±1.51 |

7.53a±0.25 |

13.33±0.56 |

5.92ab ±0.02 |

2.73b±0.10 |

|

T1 |

43.46c±0.30 |

7.43a±0.56 |

13.46±1.70 |

5.93b±0.05 |

2.78b±0.22 |

|

T2 |

35.26a±1.48 |

8.56a±0.23 |

13.46±0.35 |

5.80a±0.01 |

2.75b±0.20 |

|

T3 |

38.36c±1.48 |

11.56b±0.61 |

15.63±0.41 |

5.80a±0.05 |

2.79b±0.40 |

|

T4 |

39.16b±0.73 |

8.53a±0.96 |

14.56±0.51 |

5.93b±0.06 |

2.99ab±0.30 |

|

T5 |

34.33a±1.26 |

7.80a±1.10 |

11.96±1.78 |

5.87ab±0.04 |

2.96ab±0.10 |

|

T6 |

36.33ab±0.40 |

9.43ab±1.32 |

10.80±1.68 |

5.96b±0.06 |

3.19a±0.10 |

|

p-values |

0.00 |

0.00 |

0.102 |

0.003 |

0.007 |

|

SEM |

0.80 |

0.33 |

0.40 |

0.015 |

0.11 |

Different letters in the same column indicate significant difference at 95% probability level. * T0= 20% fat, T1= 15% fat, T2= 20% fat, T0= 10% fat, T3= 5% fat, T4= Beef fat 15% + Linseed oil emulsions 5%, T5= Beef fat 10% + Linseed oil emulsions 10%, T6= Beef fat 5% + Linseed oil emulsions 15%.

There was decrease in pH of different treatments with adding the different concentrations of emulsions such as T4 (5.80), T5 (5.81) and T6 (5.98). In cooked beef patties the pH was higher as compared to uncooked treatments due to conversion of acidic meat to alkaline with release of moisture content. According to paired t-test of pH, there was non-significant (p>0.05) difference between uncooked and cooked patties of all treatments. In a study by Özer and Çelegen (2020), olive oil oleogels-based emulsion was incorporated in beef burger as a fat replacer and found no significant difference in pH of all treatments. The outcome of current study was in accordance with this study. However, another study by Serdaroğlu et al. (2017), decrease in pH of chicken patties with high amount of olive oil gelled emulsion and increase in pH of cooked patties, these results were in accordance with observed values of current study.

Peroxide value

Peroxide value indicates the primary oxidation in meat. Hydroperoxides are the primary product of oxidation and are present in early stages of oxidation in fresh samples because these compounds are unstable. Table I shows the peroxide value of uncooked and cooked treatments, respectively. There was non-significant difference in peroxide value (p=0.507) among all treatments in uncooked treatments. The treatments with highest percentage of fat T6 showed highest value of peroxide value (0.16 meq/kg) due to abundance of double bonded fat like PUFAs in linseed oil. T4, T5 and T6 gradually possessed high values of peroxide value 2.99, 2.96 and 3.19 meq/kg, respectively. However, in cooked beef patties peroxide values were significantly higher (p=0.007) due to formation of hydroperoxides in primary oxidation during cooking process. According to paired t-test there was significant (p<0.05) difference between peroxide value of uncooked and cooked patties of all treatments.

Water holding capacity

The potential of a substance to retain water in its spatial structure is known as its water holding capacity. As a result, any element that alters the spatial configuration of the meat’s fibrillar network may affect WHC. The WHC capacity of meat is affected by factors such as animal characteristics (its breed, gender, age etc.), animal management before and after slaughter, pre- and post-rigor metabolism, storage, cooking, dehydration, and freezing. Table II shows the non-significant difference (p=0.357) in WHC of different treatments. However, the results indicate that there was a slight increase from To (64.2%) to T6 (65.66%), the WHC of any material is due to its ability of bound water and the water retained by the protein in muscle. Linseed oil emulsion increased the water holding capacity of beef patties which can be explained by the consistency of the water in gelled emulsion. Carrageenan in gelled emulsions have large particle size which supports more hydration capacity in meat systems improving the water holding capacity. The addition of pre-emulsified pumpkin seed oil in chicken meat emulsion increased its WHC with increase in emulsion of treatments (Serdaroğlu et al., 2017).

Table II. Physiochemical analysis water holding capacity and cooking yield.

|

Treatments |

Water holding capacity (%) |

Cooking yield (%) |

|

T0 |

64.20 ± 1.85 |

76.66 ± 5.77 |

|

T1 |

65.13 ± 1.09 |

72.66 ± 11.01 |

|

T2 |

63.23 ± 1.02 |

73.33 ± 5.77 |

|

T3 |

65.56 ± 2.40 |

76.66 ± 5.77 |

|

T4 |

66.00 ± 2.64 |

73.33 ± 5.77 |

|

T5 |

62.66 ± 2.08 |

73.33 ± 5.77 |

|

T6 |

65.66 ± 2.51 |

70.00 ± 10.00 |

|

p-values |

0.357 |

0.992 |

|

SEM |

0.45 |

0.33 |

Different letters in the same column indicate significant difference at 95% probability level. For details of treatments, see Table I.

Cooking yield

The cooking yield is the stabilization of fat and water by protein complex. As the protein content decreased in our obtained results it will have an impact on cooking yield of beef patties. Cooking yield is one of the most essential factors for the food sector to forecast product behavior during cooking. Table II shows no significant difference (p=0.992) in cooking yield among the treatments. There was a gradual decrease in cooking yield among the treatments containing different concentrations of emulsion T4 (73%), T5 (73%) and T6 (70%), this could be due to the moisture loss during heating due to protein denaturation. Highest cooking yield was observed in To (76%) due to higher protein value of beef patties. However, in different studies, (Serdaroğlu et al., 2017, 2018), the cooking yield of chicken meat emulsion and chicken patties was higher in treatments with incorporated pre-emulsified pumpkin seed oil and gelled olive oil emulsion. The outcome of current study is not in accordance with these studies due to difference in water holding capacity of red meat than chicken.

Sensory evaluation

A 6-membered panel evaluated beef patties for appearance, juiciness, color, texture, flavor and overall acceptance on a 9-point hedonic scale. The results showed no significance difference (p> 0.05) in appearance, flavor, juiciness, texture, color and overall acceptability among all treatments. Figure 2 explains all the parameters of evaluation in comparison to each other. Among the treatments, T6 has highest scoring in most parameters while T1 was least liked by the panel. In case of appearance, T6 and T5 were more acceptable due to addition of linseed oil emulsion. Juiciness and appearance of T6 and T5 relatively obtained higher score than other treatments. Texture of all patties showed slight difference among all treatments except T6. Replacing beef fat with plant oil emulsion showed no impact on color of all treatments. Although, surprisingly beef patties with most amount of emulsion scored best in flavor, which fulfills the motive of this study. Therefore, panelists approved all of the treatments in terms of overall acceptability. Furthermore, these findings revealed that up to 15% emulsion addition can be a good reformulation approach for obtaining beef patties that are identical to the original product. Treatments To, T1, T2, and T3 contains significantly different amounts of beef fat also demonstrated non-significant difference for sensory parameters like texture. These demonstrations indicates that hardness factor is associated with the type of fat instead of fat amount. Replacement of the beef fat with linseed oil emulsion improved the physicochemical characteristics such as cooking yield, water holding capacity and color of beef patties. Palatability characteristics of the meat products such as juiciness and tenderness are associated with the higher moisture retention and better fat distribution in meat products which is attributed to the addition of the linseed oil emulsion in meat systems. In a study by Utama et al. (2019) pre-emulsified perilla-canola oil was used as an animal fat replacer in chicken sausages, the strong nutty effect of perilla oil was covered by emulsification. Similarly obtained results indicates that strong taste of linseed emulsion was masked by formation of O/W emulsion and has more acceptability than treatments without emulsions.

Conclusion

The objective of this study was to enhance the nutritional profile and quality parameters of beef patties by replacing beef fat with linseed oil emulsion. The compositional analyses, physicochemical tests, oxidation stability and sensory analysis concluded that there was a reduction in fat quantity of beef patties, for more detailed analysis free fatty acid test should have been performed. The difference in protein and ash results were non-significant among the treatments. Moisture was increased in treatments with addition of O/W emulsion. In physicochemical analysis, WHC of treatments with emulsions was observed higher than treatments with beef fat while there was decrease in pH due to inclusion of emulsion. The difference in cooking yield was non-significant among all treatments. The peroxide values of beef patties were significantly different among all treatments and the treatment with emulsions showed higher values of peroxide due to higher PUFAs content in linseed oil. In case of sensory analysis, T5 and T6 shows more overall acceptability and other parameters of evaluation. The addition of linseed oil emulsion as a fat replacement has been proven very effective in terms of nutritional value, quality of beef patties and sensory properties.

Statement of conflict of interest

The authors have declared no conflict of interest.

References

Ahmad, R.S., Imran, A., and Hussain, M.B., 2018. Nutritional composition of meat. In: Meat Science and Nutrition. IntechOpen. https://doi.org/10.5772/intechopen.77045

Alejandre, M., Poyato, C., Ansorena, D., and Astiasarán, I., 2016. Linseed oil gelled emulsion: A successful fat replacer in dry fermented sausages. Meat Sci., 121: 107-113. https://doi.org/10.1016/j.meatsci.2016.05.010

AOAC, 2012. Official methods of analysis. Association of official analytical chemists, 19th ed. Gaithersburg MD, USA.

Barbut, S., Wood, J., and Marangoni, A., 2016. Potential use of organogels to replace animal fat in comminuted meat products. Meat Sci. 122: 155-162. https://doi.org/10.1016/j.meatsci.2016.08.003

Bentsen, H.J.M., 2017. Dietary polyunsaturated fatty acids. Brain Funct. Mental Hlth., 28: 1281916. https://doi.org/10.1080/16512235.2017.1281916

Bolumar, T., Toepfl, S., Heinz, V., and Sciences, N., 2015. Fat reduction and replacement in dry-cured fermented sausage by using high pressure processing meat as fat replacer and olive oil. Polish J. Fd. Nutr. Sci., 65: 175-182. https://doi.org/10.1515/pjfns-2015-0026

Briggs, M.A., Petersen, K.S., and Kris-Etherton, P.M., 2017. Saturated fatty acids and cardiovascular disease: Replacements for saturated fat to reduce cardiovascular risk. Healthcare, 5: 29. https://doi.org/10.3390/healthcare5020029

Câmara, A.K.F.I., and Pollonio, M.A.R., 2015a. Reducing animal fat in bologna sausage using pre-emulsified linseed oil: Technological and sensory properties. J. Fd. Qual., 38: 201-212. https://doi.org/10.1111/jfq.12136

Carpenter, J., and Saharan, V.K., 2017. Ultrasonic assisted formation and stability of mustard oil in water nanoemulsion: Effect of process parameters and their optimization. Ultrason. Sonochem., 35: 422-430. https://doi.org/10.1016/j.ultsonch.2016.10.021

Carvalho Barros, J., Munekata, P.E.S., de Carvalho, F.A.L., Pateiro, M., Barba, F.J., Domínguez, R., Trindade, M.A., and Lorenzo, J.M., 2020. Use of tiger nut (Cyperus esculentus L.) oil emulsion as animal fat replacement in beef burgers. Foods, 9: 44. https://doi.org/10.3390/foods9010044

Dzuvor, C.K., Taylor, J.T., Acquah, C., Pan, S., and Agyei, D., 2018. Bioprocessing of functional ingredients from flaxseed. Molecules, 23. https://doi.org/10.3390/molecules23102444

Franco, D., Martins, A.J., López-Pedrouso, M., Cerqueira, M.A., Purriños, L., Pastrana, L.M., Vicente, A.A., Zapata, C., Lorenzo, J.M., and Agriculture, 2020. Evaluation of linseed oil oleogels to partially replace pork backfat in fermented sausages. J. Sci. Fd. Agric., 100: 218-224. https://doi.org/10.1002/jsfa.10025

Hammad, S., Pu, S., and Jones, P.J., 2016. Current evidence supporting the link between dietary fatty acids and cardiovascular disease. Lipids, 51: 507-517. https://doi.org/10.1007/s11745-015-4113-x

Heck, R.T., Saldaña, E., Lorenzo, J.M., Correa, L.P., Fagundes, M.B., Cichoski, A.J., de Menezes, C.R., Wagner, R., and Campagnol, P.C.B., 2019. Hydrogelled emulsion from chia and linseed oils: A promising strategy to produce low-fat burgers with a healthier lipid profile. Meat Sci., 156: 174-182. https://doi.org/10.1016/j.meatsci.2019.05.034

Hosseini, A., Jafari, S.M., Mirzaei, H., Asghari, A., and Akhavan, S., 2015. Application of image processing to assess emulsion stability and emulsification properties of Arabic gum. Carbohydr. Polym., 126: 1-8. https://doi.org/10.1016/j.carbpol.2015.03.020

Li, C., 2017. The role of beef in human nutrition and health. Ensur. Saf. Qual. Prod. Beef, 2: 329. https://doi.org/10.19103/AS.2016.0009.16

Lima, T.L.S., da Costa, G.F., da Silva Araújo, Í.B., da Cruz, G.R.B., Ribeiro, N.L., Filho, E.M.B., Domínguez, R., and Lorenzo, J.M., 2021. Pre-emulsioned linseed oil as animal fat replacement in sheep meat sausages: Microstructure and physicochemical properties. J. Fd. Proc. Preserv., 45: e15051. https://doi.org/10.1111/jfpp.15051

Nacak, B., Öztürk-Kerimoğlu, B., Yıldız, D., Çağındı, Ö., and Serdaroğlu, M., 2021. Peanut and linseed oil emulsion gels as potential fat replacer in emulsified sausages. Meat Sci., 176: 108464. https://doi.org/10.1016/j.meatsci.2021.108464

Nieto, G., and Lorenzo, J.M., 2021. Use of olive oil as fat replacer in meat emulsions. Curr. Opin. Fd. Sci., 40: 179-186. https://doi.org/10.1016/j.cofs.2021.04.007

Özer, C.O., and Çelegen, Ş., 2020. Evaluation of quality and emulsion stability of a fat-reduced beef burger prepared with an olive oil oleogel-based emulsion. J. Fd. Process. Preserv., 45: e14547. https://doi.org/10.1111/jfpp.14547

Öztürk-Kerimoğlu, B., Kara, A., Urgu-Öztürk, M., and Serdaroğlu, M., 2021a. A new inverse olive oil emulsion plus carrot powder to replace animal fat in model meat batters. LWT, 135: 110044. https://doi.org/10.1016/j.lwt.2020.110044

Öztürk-Kerimoğlu, B., Kavuşan, H.S., Benzer Gürel, D., Çağındı, Ö., and Serdaroğlu, M., 2021b. Cold-set or hot-set emulsion gels consisted of a healthy oil blend to replace beef fat in heat-treated fermented sausages. Meat Sci., 176: 108461. https://doi.org/10.1016/j.meatsci.2021.108461

Paula, M.M.d.O., Silva, J.R.G., Oliveira, K.L.d., Massingue, A.A., Ramos, E.M., Benevenuto, A.A., Silva, M.H.L. and Silva, V.R.O., 2019. Technological and sensory characteristics of hamburgers added with chia seed as fat replacer. Ciência Rural, 49. https://doi.org/10.1590/0103-8478cr20190090

Peryam, D.R., and Pilgrim, F.J., 1957. Hedonic scale method of measuring food preferences. Fd. Technol., 11(Suppl.): 9-14.

Pighin, D., Pazos, A., Chamorro, V., Paschetta, F., Cunzolo, S., Godoy, F., Messina, V., Pordomingo, A., and Grigioni, G., 2016. A contribution of beef to human health: A review of the role of the animal production systems. Sci. World J., 2016: 8681491. https://doi.org/10.1155/2016/8681491

Pintado, T., Cofrades, S., 2020. Quality characteristics of healthy dry fermented sausages formulated with a mixture of olive and chia oil structured in oleogel or emulsion gel as animal fat replacer. Foods, 9: 830. https://doi.org/10.3390/foods9060830

Poyato, C., Astiasarán, I., Barriuso, B., and Ansorena, D., 2015. A new polyunsaturated gelled emulsion as replacer of pork back-fat in burger patties: Effect on lipid composition, oxidative stability and sensory acceptability. LWT Fd. Sci. Technol., 62: 1069-1075. https://doi.org/10.1016/j.lwt.2015.02.004

Rahman, M.H., Hossain, M.M., Rahman, S.M.E., Amin, M.R., and Oh, D.H., 2015. Evaluation of physicochemical deterioration and lipid oxidation of beef muscle affected by freeze-thaw cycles. Korean J. Fd. Sci. Anim. Resour., 35: 772-782. https://doi.org/10.5851/kosfa.2015.35.6.772

Ruiz-Núñez, B., Dijck-Brouwer, D.A.J., and Muskiet, F.A.J., 2016. The relation of saturated fatty acids with low-grade inflammation and cardiovascular disease. J. Nutr. Biochem., 36: 1-20. https://doi.org/10.1016/j.jnutbio.2015.12.007

Selani, M.M., Shirado, G.A.N., Margiotta, G.B., Saldaña, E., Spada, F.P., Piedade, S.M.S., Contreras-Castillo, C.J., and Canniatti-Brazaca, S.G., 2016. Effects of pineapple byproduct and canola oil as fat replacers on physicochemical and sensory qualities of low-fat beef burger. Meat Sci., 112: 69-76. https://doi.org/10.1016/j.meatsci.2015.10.020

Serdaroğlu, M., Kavuşan, H.S., İpek, G., and Öztürk, B., 2018. Evaluation of the quality of beef patties formulated with dried pumpkin pulp and seed. Korean J. Fd. Sci. Anim. Resour., 38: 1-13.

Serdaroğlu, M., Nacak, B., and Karabıyıkoğlu, M., 2017. Effects of beef fat replacement with gelled emulsion prepared with olive oil on quality parameters of chicken patties. Korean J. Fd. Sci. Anim. Resour., 37: 376-384. https://doi.org/10.5851/kosfa.2017.37.3.376

Utama, D.T., Jeong, H., Kim, J., and Lee, S.K., 2018. Formula optimization of a perilla-canola oil (O/W) emulsion and its potential application as an animal fat replacer in meat emulsion. Korean J. Fd. Sci. Anim. Resour., 38: 580-592.

Utama, D.T., Jeong, H.S., Kim, J., Barido, F.H., and Lee, S.K., 2019. Fatty acid composition and quality properties of chicken sausage formulated with pre-emulsified perilla-canola oil as an animal fat replacer. Poult. Sci., 98: 3059-3066. https://doi.org/10.3382/ps/pez105

Youssef, M.K., and Barbut, S., 2011. Fat reduction in comminuted meat products-effects of beef fat, regular and pre-emulsified canola oil. Meat Sci., 87: 356-360. https://doi.org/10.1016/j.meatsci.2010.11.011

Zhuang, X., Han, M., Kang, Z.L., Wang, K., Bai, Y., Xu, X., and Zhou, G.H., 2016. Effects of the sugarcane dietary fiber and pre-emulsified sesame oil on low-fat meat batter physicochemical property, texture, and microstructure. Meat Sci., 113: 107-115. https://doi.org/10.1016/j.meatsci.2015.11.007

To share on other social networks, click on any share button. What are these?