Technical Efficiency of Cotton Production in Pakistan: A Comparative Study on Non BT and BT-Cotton Farms

Research Article

Technical Efficiency of Cotton Production in Pakistan: A Comparative Study on Non BT and BT-Cotton Farms

Hina Fatima1*, Muhammad Azeem Khan2, Mahreen Zaid-Ullah3, Abdul-Jabbar4, Khurram Nawaz Saddozai5

1Fatima Jinnah Women University, Rawalpindi, Punjab, Pakistan; 2National Agricultural Research Council, Islamabad, Pakistan; 3Mirpur University of Science and Technology, Mirpur, Pakistan; 4International Islamic University, Islamabad, Pakistan; 5University of Agriculture Peshawar, Khyber Pakhtunkhwa, Pakistan.

Abstract | This study has estimated the technical efficiency of Non-BT cotton and BT cotton production in Pakistan. Those farmers were selected as the respondents for the study that used to cultivate Non-BT cotton and BT cotton varieties. In Pakistan, the NonBT cotton varieties have been promptly substituted with the BT-cotton varieties. This substitution of imported BT-cotton seed is taking into account without considering the local environmental conditions of Pakistan. Thus the main objective of the research was on the comparative efficiency and the productivity analysis of BT- Cotton varieties with those of the conventional non-BT-Cotton varieties. The population of this research covers the area of Rahim Yar Khan of Pakistan. Two hundred and fifteen farms were selected from each of the NonBT-cotton farms and BT-cotton farms. The Cobb- Douglas Stochastic Frontier Analysis (SFA) has been employed to determine the technical efficiency of these growers. Technical efficiency has been found dissimilar under both the situations. The estimated mean technical efficiency of NonBT cotton farmers has been found to be 0.70, and 0.90 is the technical efficiency found in that of the BT cotton farmers. Hence the average output of Non-BT cotton and BT-cotton farms could be increased by 30 and 10 percent, respectively by adopting the technology with an appropriate approach. The results of the inefficiency model reveal that the factors like education, experience and distance from the main market, are the most influential determinants of the technical efficiency in both NonBT and BT- cotton farms. Extension of cotton production required the development of cottonseed that will be suitable for environmental conditions of Pakistan.

Received | July 14, 2016; Accepted | August 30, 2016; Published | September 26, 2016

Correspondence | Hina Fatima, Fatima Jinnah Women University, Rawalpindi, Punjab, Pakistan; Email: [email protected]

Citation | Fatima, H., M.A. Khan, M. Zaid-Ullah, A. Jabbar, K.N. Saddozai. 2016. Technical efficiency of cotton production in Pakistan: A comparative study on non BT and BT-cotton farms. Sarhad Journal of Agriculture, 32(4): 267-274.

DOI | http://dx.doi.org/10.17582/journal.sja/2016/32.4.267.274

Keywords | BT-cotton, Non-BT cotton, Techncial Efficiency, Cobb-Douglas, Pakistan

Introduction

Farming sector plays a persuasive role in the development of the economy of a country like Pakistan. Pakistan’s temperature, climate, and fertile soil have supported almost every kind of farming across different regions. Conventional or Non BT-cotton varieties have been rapidly replaced by BT-cotton varieties. In Pakistan, returns from cotton crop back more than 45 percent headed for the domiciliary income of farmers (PARC, 2009-10). According to a Pakistan Agricultural Research (2015) report, Millions of farmers are directly associated with the cultivation, harvest, and sale of cotton in Pakistan.

The area under cotton cultivation is declining on a regular basis since 2004-05. According to Arshad et al. (2007), the cotton yield of 14.62 million bales approximately, was highest in 2004-05. According to Agricultural Statistics of Pakistan (2011), cotton production had then sustained at about 700 kg/ha approximately during 2005-10, despite rapid adoption of BT cotton varieties. On the other hand, BT varieties have created Mango Mealy bug Problem in Pakistan and India; and Mirid Bug in China, which is affecting other food crops like wheat, citrus, vegetables etc. According to the GoP (2015), the cotton production in 2013-14 was 12769 million bales per hectare and the projected yield for 2014-15 was 13983 million bales per hectare. However, in 2014 and 2015, the government made policy to set the target around fifteen million bales.

According to the report of Pakistan Agricultural Research Council (PARC, 2008) in 2009-10, a significant proportion of total BT cotton planted under fake BT has cost the nation by about 19 billion rupees and , above half million farmers used the fake BT Seed. The cotton production has declined by 17.1 percent (from 14.265 million bales in 2004-05 to 11.819 million bales in 2008-09). In Pakistan, it is possible to produce approximately 20 million cotton bales each year. By the introduction and use of domestically evolved BT cotton seed during 2015-16, scientists are striving to achieve the output target of fifteen to twenty millions of bales. The output of cotton crop targeted at 15 million bales by the government for the year 2014-15 missed the target by about four million bales. The main factors that have resulted in this shortfall are exorbitant imported seed used; unsuitable for the local environment, substandard seed quality, lack of expertise on the farmers’ side to utilize the alien seed efficiently and the altered climatic conditions.

Measuring farm efficiency is an essential subject to the agricultural field (Hazarika and Subramanian, 1999). A small number of studies undertook to measure the technical efficiency of the cotton crop. A few studies have also been done in the examination of the issues regarding the productivity and the technical efficiency of the cotton crop’s output (Helmers and Weiss, 2000; Woosink and Denaux, 2006; Javed et al., 2009). Javed et al. (2009) pointed out that estimation of technical efficiency can still be regarded a research jurisdiction, for both the developed and developing countries. It is in fact very important especially in the case of developing country like Pakistan, where lies a great chunk of potential to elevate the output, and this can be accomplished via extension in the cultivated land area along with the adoption of suitable technology. Johnston and Cowine (1969), emphasized on the experience, knowledge and technical skill of the farmers, as the output depends not only on the levels of resource use, but also on the ways in which it is used. Coady (1995) explains that accessibility with respect to the knowledge also upturns the farm productivity. The major objective of the current research is to get the estimates for the technical efficiency of BT cotton growers vs. Non-BT cotton growers.

Materials and Methods

The respondents of the study were those farmers that cultivate Non-BT and BT-cotton. The population of this research covers the area of Rahim Yar Khan of Pakistan, where cotton is the most popular cash crop. In the study, 215 farms were selected from Non BT cotton farms and 215 from BT-cotton farms.

According to Bravo-Ureta and Rieger (1991), measuring efficiency is important from an applied perspective that might lead to considerable resource saving. In microeconomics of production, technical efficiency is defined as “the maximum attainable level of output for a given level of inputs, given the current range of alternative technologies available to the farmer” (Ellis, 1993). In technical efficiencyanalysis, usually two approaches, the Data Envelopment Analysis (DEA) and the Stochastic Frontier Analysis (SFA) are preferred. Researchers have applied it to examine the performance of non-profit and the profit organizations. The scores of the efficiency, acquired from the DEA are only relative to the best firms in the sample. Technical efficiency scores remain the same for the marginal addition of firms in the DEA analysis. Finely documented is the idea that the DEA approach operates with the assumption of zero random shocks exists in the data set as the farmers have always an uncertain situation before. On the other hand, Stochastic Frontier Analysis (SFA) assumes that deviation from production frontier may not be completely controllable by farmers (Aigner et al., 1977). SFA is preferred over DEA, according to Coelli (1995) and Ezeh (2004), there is natural stochasticity involvement in agriculture. For the efficiency assessment in the current study, the stochastic frontier method is selected. It aids to differentiate and segregate the stochastic noise effects from the other inefficiency factors’ effects. The Cobb-Douglas and Translog specifications have commonly been employed for having the estimates of the frontier models.

The Cobb-Douglas is a function fulfilling homogeneity gives a scale factor allowing estimating for the returns to scale and to construe the elasticity coefficients with much ease comparatively. Also, it provides many degrees of ease to estimate and handle mathematically (Coelli et al., 1998). The Translog functional form requires a large sample size of its functional form. According to Koop and Smith (1980), functional specification has an evident but the fairly small impact on the estimates for efficiency. Xu and Jeffrey (1997) argued that functional specification affects the empirical efficiency measurement, limitedly. A Number of studies have used the Cobb-Douglas Stochastic Frontier Production Analysis (Basnayake and Gunaratne, 2002; Hassan, 2004; Croppenstedt, 2005). This study takes a stochastic production frontier approach introduced by Aigner et al. (1977) and Meeusen and Van den Broeck (1977).

The stochastic frontier method assumes that the production function includes the double random error, is written as:

Where, Y = f (xi, B)and exp (vi – ui) show the deterministic and stochastic parts of the production frontier, respectively. ‘Here, ‘v’is the error component which is symmetric and assumed to be normally, independently and identically distributed as vi~ N (0, σ2). It stands for the random output variations due to factors not controllable by the farmer. On the other hand, ‘ui’ which can only be positive, shows the technical inefficiency relative to the stochastic frontier (Neff et al., 1993). Its distribution by assumption is half normal, accompanied by the characteristics of being identical and independent, as N (0, σ2).

TE denotes the technical efficiency of the ith farm and is calculated by dividing the observed output level, by the maximum output possible using the given level of input.

Mostly, varieties of Non BT and BT cotton are produced in the study area. Separate Cobb-Douglas production functions have been estimated for the two varieties of cotton.

Non BT- cotton’s production frontier is written as:

Where Yi depicts here the per unit yield of Non-BT cotton for the ith farm; Xi is the vector of x1i, x2i,……x6i inputs for the ith farm; the size of the farm under cotton crop is represented by X1i; X2i is the NPK ratio; X3i stands for the per Kg seed rate per acre; the number of irrigations per acre is denoted by X4i; X5i has the representation of the number of pesticide sprays and the number of tractor-hours spent in all the farm practices on the ith farm from planking, ploughing, hoeing and riding to the spraying, land leveling and fertilizing etc. is depicted by X6i .

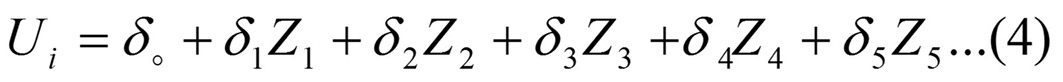

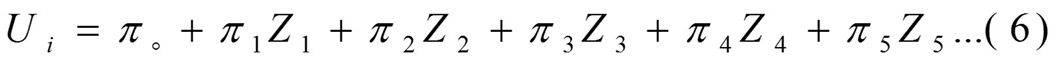

The technical inefficiency effects are defined as:

Where Z1 =Years of the farmer’s education; Z2 = Experience of the farmer in years; Z3= shows the ratio of own land to total land operated.Z4 = Dummy variable which becomes one if the farmer owner of the tractor and zero otherwise; Z5= shows the farm distance from the market.

Where again, Yi represents the per unit BT- cotton output for the ith farm; Xi description is same as mentioned in equation No. 3.

The technical inefficiency effects are defined as:

Where Ui, is the technical inefficiency scores, obtained by BT-cotton farms, Zi variables description is similar to equation No. 4.

The descriptive analysis has been done prior to the empirical estimation for illustrating the descriptive statistics of the key variables.

In the year 2010-11, cotton was the most popular cash crop in Pakistan. Farmers in this study area receive marginal rains which have given the farmers a feasible substitute to the rice crop from cotton crop, which is drought resistant.

Table 1 specifically shows the cotton sowing dates spread at Non-BT and BT-cotton fields. The results show that most commonly, 88% of the cotton is planted conventionally between 11th and 20th of May. On the other hand, BT cotton is mainly planted between 20th of April and10th of May.

| Sowing Dates Spread | Non-BT Cotton Field | BT-cotton fields | Prob. |

| Percent Growers | |||

| Before April 20 | 0 | 9 |

.000 |

| April 20 to 30 | 0 | 33 | |

| May 1 to 10 | 6 | 54 | |

| May 11 to 20 | 88 | 3 | |

| Above May 20 | 6 | 0 | |

Table 2: Cotton Harvesting Dates

| Harvesting Dates Spread | Non-BT Cotton Field | BT-cotton fields | Prob. |

| Percent Growers | |||

| Before 10 November | 23 | 0 |

.000 |

| 10 to 20th November | 60 | 1 | |

| November 20 to 30 | 16 | 66 | |

| Above 1st December | 0 |

32 |

|

Table 2 displays the harvesting spread of cotton in Non-BT and BT-cotton fields. The 60% of the Non-BT cotton area was commonly picked between 10th and 30thof November. 23% and 16% area picked before 10th and between 20th and 30th of November, respectively. In the case of BT- cotton, 41% of the area was commonly picked between 20th and 30thof November. After the 1st of December, around 31% and 16% area harvested respectively. Only 12% BT-cotton area harvested before 10th November. Hence, Table 1 and 2 clearly shows the early sowing and late harvesting characteristics of the BT- cotton compared to the Non-BT cotton varieties.

Table 3: Cotton Yield on Non BT and BT-cotton Field

| Particulars |

Non-BT Cotton Field |

BT-cotton fields | Prob. | ||

| Mean | SD | Mean | SD | ||

|

Cotton yield per acre (Muand) |

22 | 5.7 | 25.4 | 6.7 |

.000 |

Table 3 demonstrates the Non-BT and BT-cotton yields per acre (One hector is equal to the 2.47 acre). Non-BT yield per acre, was approximately 22 maund’s per acre; whereas the BT cotton yield per acre, was 25.4 maunds (One maund is equal to the 40 Kg).

In total, for the BT cotton, 17 parameters were estimated with the stochastic production frontier specification. Seven parameters were in the stochastic frontier model, 8 were in the model for inefficiency and the rest two parameters, square of sigma and the gamma relate to the respective variances of Viand Ui which are the random variables.

Table 4 show a maximum likelihood of BT cotton parameter estimates obtained from the inefficiency and the frontier production functions. The estimate of γ is 0.928 and is statistically significant also (Table 4). This satisfies the theory that the true gamma should lie between zero and one. The gamma estimate which is 0.928 shows the magnitude of variation consequent upon the technical inefficiencies of BT cotton farms. So, the technical efficiency difference is the main culprit for the 92% of the variation in the farmers’ production.

Table 4: Maximum Likelihood Estimation of the Cobb-Douglas Stochastic Production Frontier

| Frontier Function of BT Cotton Farms | ||||

| Variables | Para- meters | Coefficient | t-ratio | |

| Stochastic Production Frontier | ||||

| Constant |

β° |

5.258 | 7.770*** | |

| Ln(Farm size) |

β1 |

0.044 | 2.016** | |

| (NPK ratio) |

β2 |

0.030 | 0.207 | |

| Ln(Seed rate) |

β3 |

0.078 | 2.226** | |

| Ln(# of irrigation) |

β4 |

0.688 | 1.699* | |

|

Ln(# of pesticide sprays) |

β5 |

-0.767 | 1.862* | |

| Ln(# of tractor hour ) |

β6 |

0.133 | 1.663* | |

| Inefficiency Effects | ||||

| Constant |

δ° |

-0.320 | -2.386** | |

| Education |

δ1 |

-0.161 | -2.547*** | |

| Experience |

δ2 |

-0.134 | -0.601 | |

| Own land to operated land ratio | δ3 | -0.563 | -2.166** | |

| tractor ownership | δ4 | 0.670 | 2.218** | |

| distance market | δ5 | -0.733 | 2.559*** | |

| Variance Parameters | ||||

| Sigma squared | 1.346 | |||

| Gamma | 0.928 | |||

| Log Likelihood function | -135.167 | |||

*: 10% significance; **: 5% significance; ***: 1% significance

Farm size coefficient under BT-Cotton is positive along with being statistically significant. This result shows that cotton production increases as the area under BT-cotton surges. Parallel results are acquired by Basnayake and Gunaratne (2002) and Barnes (2008). The coefficient of the NPK ratio variable is positive and insignificant. The coefficient of seed rate for the BT-cotton crop has a positive sign and statistically significant. The coefficient for pesticide cost is negative in sign and has the significance statistically. Consequently, as farmers spend more money for the purchase of pesticide spray, it leads to decrease the BT-cotton productivity. The primary culprit for this negative coefficient is that the farmers use pesticides exorbitantly as these are employed at the rate higher than the one that is recommended. Relative to the Non BT-cotton, BT cotton requires lesser Pesticide spray. Thus, over use of pesticide spray results in higher production cost without any increase in BT-cotton yield. The positive and significant coefficient of the number of irrigations is indicating that cotton productivity rises as the number of irrigations increase. This result is in conformity with Ahmad and Ahmed (1998), Bashir et al. (2005), Hassan (2004) and Ahmad et al. (2002). The coefficient for the number of tractor-hours spent for the entire farm operations, including planking, ploughing, hoeing ridging, spraying fertilizing, and land leveling, has a positive sign with the statistical significance.

The estimation of the technical inefficiency model for BT cotton farms is accomplished by using equation “2” where it is assumed that the inefficiency is regressand. The parameter estimates for the model of inefficiency are also given in Table 4. The coefficient for the education is negative and statistically significant. This result implies education of farmers is an important factor in enhancing BT cotton productivity. A farmer with more schooling years tends to be less technically inefficient. This result is consistent with those of Bettese et al. (1996) and Bakhsh (2006). The coefficient of experience of the farmer is negative, but statistically not significant. The parameter estimates of the distance from the main market in kilometers carry a negative association with inefficiency and are statistically significant. The result demonstrates that the farm inefficiency declines as the distance from market, decrease and thus the productivity would significantly increase. The coefficient for the dummy of the tractor ownership is positive and carries with its statistical significance at five percent. This result indicates that those farmers are technically less inefficient, which own the tractors relative to those which have tractors obtained on rent. Tenurial measures play a significant and substantial role in determining the inefficiencies associated, at the farm level. For the representation of a tenurial variable, the ratio of own land to total land operated variable is developed. The value estimated for the parameter, carry the negative sign. Subsequently, it reveals that those farmers have more share of own land are technically more efficient. It reveals that farmers feel more tenure secure by working their own land.

Table 5 illustrates the results for the Non BT-cotton estimates. A total of 15 parameters were also estimated for the Non-BT cotton with the stochastic production frontier specification.

Table 5: Maximum Likelihood Estimation of the Cobb-Douglas Stochastic Production Frontier

| Frontier Function of Non BT- Cotton Farms | ||||

| Variables | Para- meters | Coefficient | t-ratio | |

| Stochastic Production Frontier | ||||

| Constant |

α° |

5.955 | 2.561** | |

| Ln(Farm size) |

α1 |

-0.002 | -0.137 | |

| (NPK ratio) |

α2 |

0.515 | 1.776* | |

| Ln(Seed rate) |

α3 |

0.790 | 2.411** | |

| Ln(# of irrigation) |

α4 |

0.643 | 5.722* | |

| Ln((# of pesticide sprays) |

α5 |

0.979 | 5.720* | |

| Ln(of tractor hour |

α6 |

0.910 | 2.368** | |

| Inefficiency Effects | ||||

| Constant |

π° |

3.543 | 1.712* | |

| education |

π1 |

-0.535 | -1.972* | |

| experience |

π2 |

-0.260 | -2.149** | |

| Own land to operated land ratio |

π3 |

-0.319 | -2.183** | |

| tractor ownership |

π4 |

0.496 | 1.802* | |

| distance market |

π5 |

-0.607 | 2.658*** | |

| Variance Parameters | ||||

| Sigma squared | 28.2843 | |||

| Gamma | 0.6949 | |||

| Log Likelihood function | -561.173 | |||

*: 10% significance; **: 5% significance; ***: 1% significance

The estimate for the γ is 0.694 which has statistical significance (Table 5). This value of gamma depicts the magnitude of variation, consequent upon the technical inefficiencies in the Non BT-cotton farms. This means that 69% of the variation in the production of the farmer is coming from the disparity in the farmer’s level of technical efficiency. The value estimated for the gamma, is different from one, significantly, demonstrating that the random shocks are very crucial in explaining the variation in the output of Non BT-cotton.

The coefficient of farm size under Non BT-cotton is negative statistically insignificant. Thus the present study has not been able to divulge that Non BT-cotton farmers face diminishing returns to scale in the study area. This result confirms that of Ahmad et al. (2002). The coefficient of NPK ratio for Non BT-cotton crop has a positive sign and is statistically significant as well. For attaining improved cotton yield, rational application of fertilizer is important. It is found that seed rate, pesticide cost, the number of irrigations and the number of tractor hours have a positive and highly significant impact on the yield of the Non BT-cotton.

In inefficiency function of Non BT-cotton farmers, the coefficient for the education and experience variables is negative and is significant as well, statistically. This result reveals that the education and the experience of the farmer are key factors in enhancing the NonBT-cotton growers’ technical efficiency. Tenurial parameter estimate is calculated again as the ratio of own land to total land operated. The coefficient of the ratio of own land to a total land variable has a negative relationship with technical inefficiency and possesses statistical significance. Hence, these owner farmers that have more ratio of own land are technically more efficient. The coefficient associated with the distance from the main market is negative and contains significance, statistically. This suggests that as the farm distance decreases from the market, there is a reduction in the technical inefficiency of NonBT-cotton growers. The coefficient for the tractor ownership dummy is positive and has statistical significance.

Table 6: Frequency Distribution of Technical Efficiency of Non-BT and BT cotton Farms

| Non BT Farms | BT Farms | ||||

| Efficiency Level | Frequency | % | Efficiency Level | Frequency | % |

| 0-0.20 | 5 | 2.33 | 0-0.20 | 0 | 0.00 |

| 0.21-0.40 | 11 | 5.12 | 0.21-0.40 | 1 | 0.47 |

| 0.41-0.60 | 22 | 10.23 | 0.41-0.60 | 2 | 0.93 |

| 0.61-0.80 | 97 | 45.12 | 0.61-0.80 | 6 | 2.79 |

| 0.81-0.90 | 61 | 28.37 | 0.81-0.90 | 44 | 20.47 |

| Above 90 | 19 | 8.84 | Above 90 | 162 | 75.35 |

| Total | 215 | 100 | Total | 215 | 100 |

| Mean | 0.70 | Mean |

0.90 |

||

The frequency distribution of estimated technical efficiency for NonBT and BT cotton growers is given in Table 6. The cases of Non-BT and BT cotton groups are discussed, separately.

The results reveal that the mean technical efficiency ranges from 0.11 to 0.93 percent and from 0.33 to 0.96 percent of Non BT-cotton and the BT-cotton farms, respectively. This suggests that there lies a great chunk of potential to elevate the per acre Non BT and BT cotton yields. The mean technical efficiency turned out to be 0.70 percent for the Non BT-cotton and 0.90 percent of BT cotton growers. This indicated that those farmers, who used to cultivate the BT-cotton, were about 20 percent more efficient than those farmers who cultivated Non BT-cotton. The stochastic frontier estimates of technical inefficiency resulted in being 30 percent of Non BT-cotton farms and 10 percent of BT-cotton farms. In other words, Non BT cultivating farmers can increase the production of cotton by 30 percent and BT-cotton growers can by 10 percent just by way of realizing efficiency, without necessarily increasing the extent of inputs. The result of technical efficiency scores also implies that BT-cotton farmers are technically 20 percent more efficient than Non BT-cotton growers in the use of inputs and thus attain stronger response in term of cotton output.

Conclusions

The study utilizes the stochastic production frontier approach to estimate the technical efficiency in BT and Non-BT cotton production. Results showed that the BT cotton farmers were more efficient in the use of the included variable inputs compared to the NonBT-cotton farmers. In the case of technical efficiency of Non-BT and BT-cotton groups, the results revealed that the mean technical efficiency ranged from 70 percent on Non-BT cotton farms to 90 per cent of BT-cotton farms. This indicated that those farmers, who cultivated BT-cotton, were about 20 percent technically more efficient than those farmers who cultivated Non-BT cotton. The stochastic frontier analysis of NonBT and BT cotton has further shown the 69 and 92 percent of the observed inefficiency consequent upon the farmers’ inefficiency in decision making. It is possible for Non-BT and BT-cotton farmers to expand the productivity in cotton, by elevating the production efficiency at the farms which are relatively inefficient, without increasing the level of inputs and by using efficient management practices.

For the expansion in cotton production in Pakistan, it is necessary to develop domestically, the high yielding cotton seed varieties that are best suited to the environmental conditions of Pakistan, instead of instinctively importing the BT-cotton varieties.

There is a need for the research programs to include advancement of high yielding varieties of cotton, which will, in turn, create additional opportunities to improve the farmers’ income. This will also lend a hand in strengthening the Pakistan’s economy.

Authors’ Contribution

All the authors have contributed substantially to the current research work. The idea was conceived by the main author (Hina Fatima). Data collection, estimation and result and discussion are done by the main author, the technical back stopping and suggestions by reviewers and experts were incorporated by the co-authors.

References

Abedullah., K. Bakhsh and B. Ahmad. 2006. Technical Efficiency and its Determinants in Potato Production Evidence from Punjab Pakistan. Lahore J. Econ. 11(2):1-22.

Agriculture Statistics of Pakistan. 2011. Government of Pakistan Statistics Division Pakistan Bureau of Statistics.

Ahmad, M., and A. Ahamd. 1998. An Analysis of the Sources of Wheat Output Growth in the Barani Area of the Punjab. Pak. Dev. Rev. 37:231–249.

Ahmad, M., G.C. Mustafa and M. Iqbal. 2002. Wheat Productivity, Efficiency, and Sustainability A Stochastic Production Frontier Analysis. Pak. Dev. Rev. 41:643-663.

Aigner, D., C.K. Lovell and P. Schmidt. 1977. Formulation and estimation of stochastic frontier production function models. J. Econ. 6(1):21-37. http://dx.doi.org/10.1016/0304-4076(77)90052-5

Arshad, M., A. Wajid, M. Maqsood, K. Hussain, M. Aslam and M. Ibrahim. 2007. Response of growth, yield and quality of different cotton cultivars to sowing dates. Pak. J. Agri. Sci. 44(2):208-212.

Azhar, R.A. 1991. Education and technical efficiency during the green revolution in Pakistan. Econ. Dev. Cult. Change. 39(3):651-665. http://dx.doi.org/10.1086/451894

Bakhsh, K., B. Ahmad and S. Hasssan. 2006. Food security through increasing technical efficiency. Asian J. Plant Sci. 5:970-976.

Barnes, A. 2008. Technical efficiency estimates of Scottish agriculture: A note. J. Agri. Eco. 59(2):370-376. http://dx.doi.org/10.1111/j.1477-9552.2008.00156.x

Bashir, M., D. Khan and M. Iqbal. 2005. An analysis of allocative efficiency of wheat growers in Northern Pakistan. Pak. Dev. Rev. 44:643-657.

Basnayake, B.M.J.K., and L.H.P. Gunaratne. 2011. Estimation of technical efficiency and it’s determinants in the tea small holding sector in the Mid Country Wet Zone of Sri Lanka. SR. J. Agri. Econ. 4: 137-150.

Battese, G.E., S.J. Malik and M.A. Gill. 1996. An investigation of technical inefficiencies of production of wheat farmers in four districts of Pakistan. J. Agri. Econ. 47(1‐4):37-49. http://dx.doi.org/10.1111/j.1477-9552.1996.tb00670.x

Belknap, J., and W.E. Saupe. 1988. Farm family resources and the adoption of no-plow tillage in Western Wisconsin. N.C.J. Agri. Econ. 10: 13-23. http://dx.doi.org/10.2307/1349232

Bravo-Ureta, B.E., and L. Rieger. 1991. Dairy farm efficiency measurement using stochastic frontiers and neoclassical duality. Am. J. Agric. Eco. 73(2):421-428. http://dx.doi.org/10.2307/1242726

Foreman, L. 2012. Characteristics and production costs of US cotton farms, 2007. US Department of Agriculture, Economic Research Service.

Coady, P.D., 1995. An empirical analysis of fertilizer use in Pakistan. J. Econ. 62:13-234. http://dx.doi.org/10.2307/2554904

Croppenstedt, A. 2005. Measuring technical efficiency of wheat farmers in Egypt. The Agricultural Development Economics Division (ESA) is the focal point for FAO’s economic research and policy analysis for food security and sustainable development, Egypt.

Coelli, T., D.S.P Rao and G. Battese. 1998. An introduction to efficiency and productivy analysis, Boston: Kluwer Academic Publishers. http://dx.doi.org/10.1007/978-1-4615-5493-6

Coelli, T.J. 1995. Recent Developments in Frontier Modeling and Efficiency Measurement. Aus. J. Agri. Econ. 39(3):219-245.

Ellis, F. 1993. Peasant economics: Farm households in agrarian development. Vol. 23. Cambridge University Press.

Ezeh, C.I. 2004. A comparative study of Fadama and non-Fadama crop farmers in Osisioma-Ngwa LGA, Abia State, Nigeria. J. Sust. Trop. Agric. Res. 11:26-31.

Farrell, M.J. 1957. The measurement of productive efficiency. J. R. Stat. Soc. Series B. Stat. 120(3):253-290. http://dx.doi.org/10.2307/2343100

Government of Pakistan (GoP) 2015. Economic Survey of Pakistan, Ministry of Finance Islamabad.

Hassan, S. 2004. An analysis of technical efficiency of wheat farmers in the mixed farming system of the Punjab, Pakistan. Department of Environmental & Resource Economics, University of Agriculture, Faisalabad.

Hazarika, C., and S.R. Subramanian. 1999. Estimation of technical efficiency in the stochastic frontier production function model: An application to the tea industry in Asam. Ind. J. Agric. Econ. 54(2):201-221.

Helmers G.A., and S.S. Weiss. 2000. Impact of climatic change on efficiency and productivity in cotton and wheat producing regions. Paper presented at the Annual Meeting of Southern Agricultural Economic Association. Lexington, KY.

Javed, I.M. A.S. Adil, S. Hassan and S. Ali. 2009. An efficiency analysis of Punjab Cotton-Wheat System. Lahore. J. Econ. 14(2):97-124.

Johnston, F.B., and J. Cowine. 1969. The seed-fertilizer revolution and labor force absorption. Am. Econ. Rev. 4(59):569-582.

Koop, R.J., and V.K. Smith. 1980. Frontier production function estimates for a steam electric generation: A comparative analysis. South Econ J. (47):1049–1059. http://dx.doi.org/10.2307/1057240

Meeusen, W., and J. Van den Broeck. 1977. Efficiency estimation from Cobb-Douglas production functions with composed error. Int. Econ. Rev. 18:435-444.

Neff, D.L., P. Garcia and C.H. Nelson. 1993. Technical efficiency: A comparison of production frontier methods. J. Agri. Econ. 44:479-489. http://dx.doi.org/10.1111/j.1477-9552.1993.tb00289.x

Pakistan Agricultural Research. 2015. Cotton Crop in Pakistan. Available on the world wide web: http://edu.par.com.pk/wiki/cotton/

Pakistan Agricultural Research Council (PARC). 2008. Status of cotton harboring Bt gene in Pakistan. Islamabad: Institute of Agri-Biotechnology & Genetic Resources, National Agricultural Research Centre, PARC.

Son, T.V.H., T. Coelli and E. Fleming. (1993). Analysis of the technical efficiency of state rubber farms in Vietnam. Agri. Econ. 9(3):183-201.

Wossink, A., and Z.S. Denaux. 2006. Environmental and cost efficiency of pesticide use in transgenic and conventional cotton production. Agric. Syst. 90(1):312-328. http://dx.doi.org/10.1016/j.agsy.2006.01.004

Xu, X., and S.R. Jeffrey. 1998. Efficiency and technical progress in traditional and modern agriculture: Evidence from rice production in China. Agric. Econ. 18:157-165. http://dx.doi.org/10.1016/S0169-5150(97)00050-9

To share on other social networks, click on any share button. What are these?