Comparison between Natural and Cabinet Drying on Weight Loss of Seaweed Euchuema cottonii Weber-van Bosse

Comparison between Natural and Cabinet Drying on Weight Loss of Seaweed Euchuema cottonii Weber-van Bosse

Suwati Suwati1, ErniRomansyah1,*, Syarifudin Syarifudin1, Yahya Jani2, Agus Heri Purnomo3,

Damat Damat4 and Erkata Yandri5,6

Cabinet dryer machine (A) and tray manual sun drying (B).

Fresh seaweed (A) and dried seaweed (B) Eucheuma cottonii.

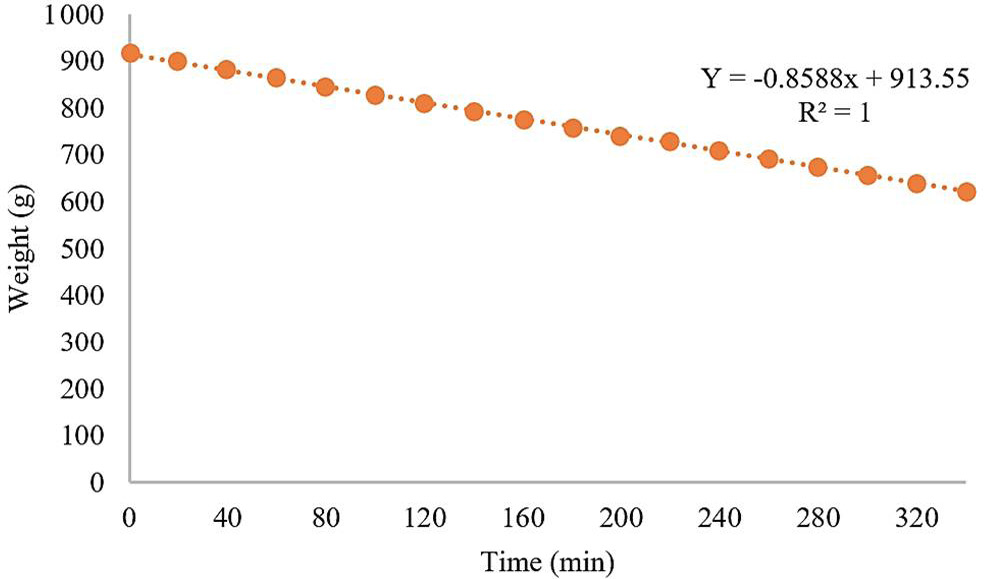

Reducing the weight of seaweed (g) at 40 °C used cabinet dryer.

Prediction of the seaweed weight loss rate model.

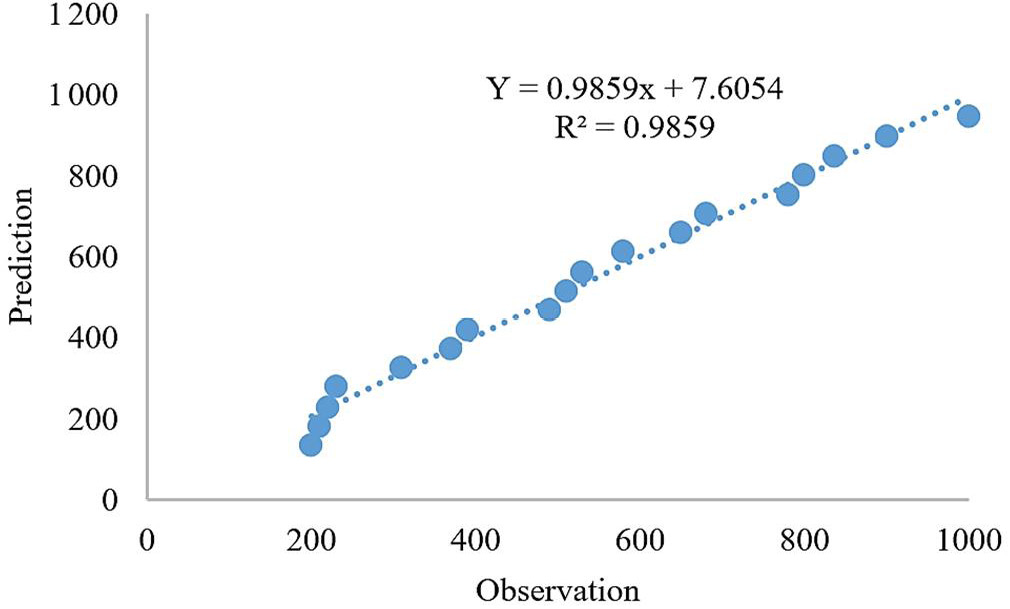

Validation of the seaweed weight reduction rate model.

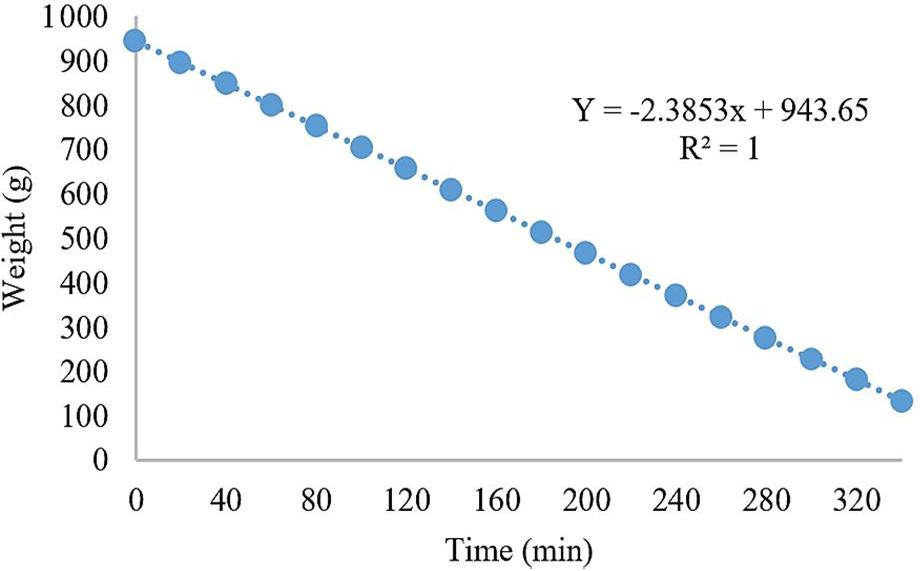

Decreased weight of seaweed with sunshine.

The drying process of seaweed.

Prediction of the seaweed weight loss rate model.

Validation of the seaweed weight reduction rate model.