Effect of Drying Temperature on the Physico-Chemical Properties of Carrot Peel Powder

Research Article

Effect of Drying Temperature on the Physico-Chemical Properties of Carrot Peel Powder

Nguyen Tuyet Giang1,2*, Le Thi Thuy Hang1,2, Phan Phuong Loan1,2 and Le Thi Thuy Loan1,2

1An Giang University, An Giang, Vietnam, 2Vietnam National University Ho Chi Minh City, Vietnam

Abstract | The objective of this study was to evaluate the physio-chemical properties of carrot peel powders obtained at four hot-air drying temperatures (50, 60, 70, and 80°C). The drying process ended when the materials achieved the moisture content of about 5-7%. The final products were subsequently analyzed for water activity, hydration indices, chemical composition, and color attributes to evaluate the influence of drying temperature on the quality of carrot peel powder. The results showed that the increment in drying temperature increased the hydration properties, the values of L*, and ΔE*, but reduced the contents of protein, and total carotenoids, as well as the values of a*, b*, and C*. In the range of hot-air conditions tested in this study, it is suggested to use an operating temperature of 50°C to minimize changes in the physico-chemical properties of the carrot peel powder. This is a preliminary study to optimize the drying conditions to produce carrot peel powder with high physico-chemical properties. Further studies will focus on investigating the effect of carrot peel powder on the performance of laying chickens.

Received | February 08, 2024; Accepted | August 20, 2024; Published | August 27, 2024

*Correspondence | Nguyen Tuyet Giang, An Giang University, An Giang, Vietnam; Email: ntgiang@agu.edu.vn

Citation | Giang, N.T., L.T.T. Hang, P.P. Loan and L.T.T. Loan. 2024. Effect of drying temperature on the physico-chemical properties of carrot peel powder. Pakistan Journal of Agricultural Research, 37(3): 232-240.

DOI | https://dx.doi.org/10.17582/journal.pjar/2024/37.3.232.240

Keywords | Carotenoids, Carrot peel, Colour, Drying yield, Hydration properties, Moisture

Copyright: 2024 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

The by products or wastes from the agro-food industry may not be disposed of properly, contributing to water and soil contamination and ultimate climate change. According to FAO (2019), about 14% of food is lost and wasted during the supply chain, via processing, distribution, retailing, and consumption. Within the processing of fruits and vegetables, it is estimated that 50% of the residues are generated in the form of pulp, seeds, peels, immature and damaged products (Amran et al., 2021). Therefore, to deal with the food and feed shortage arising from the current demand, it needs to explore the potential use of these residues as valuable sources with their health-promoting properties (Gowe, 2015; de Oliveira Sousa Wanderley et al., 2023).

The Apiaceae is a cosmopolitan family which includes 466 genera and 3.800 species, making this family one of the largest taxon among higher plants (Reduron, 2021). Plants of the Apiaceae family are cultivated throughout the world, not only as vegetable crops but also as medicinal and aromatic plants with diverse functional properties, such as herbicidal, insecticidal, and antimicrobial activities (Thiviya et al., 2022). The most notable species is the carrot (Daucus carota L.), followed by celery (Apium graveolens), parsley (Petroselinum crispum) and parsnip (Pastinaca sativa). According to the official statistics from FAO, the global production of carrots and turnips was about 41.7 million tonnes in 2021, with an average yield of 38.0 tonnes/ha (FAOSTAT, 2021).

Carrot, a multi-nutritional food source, is known to have a wide range of bioactive compounds, such as dietary fiber, vitamins, carotenoids, anthocyanins, ascorbic acid, and polyacetylenes (Sharma et al., 2012; Krivokapić et al., 2020; Ahmad et al., 2019). The industrial processing of carrots produces a large amount of by products and waste, up to 175,000 tonnes annually in the form of out-graded, peels, petioles, pomace, and cuts of ready-to-eat products. These sources are generally edible and nutrient-dense; but only a small portion is used for animal feeding or biogas generation. The majority may end up in landfills, causing global warming effects by generating greenhouse emission (Amin et al., 2021; Kaur et al., 2022).

Previous studies found that carrot peels are potential sources of natural antioxidants. Total phenolic and flavonoid contents were high in the peel acetone extract, which showed a direct link between its antioxidant capacity and free-radical scavenging activity. These phenolic compounds also worked as antimicrobial agents by inhibiting the growth of S. flexneri, E. coli, S. aureus, and K. pneumonia, the foodborne disease-causing pathogens (John et al., 2017). In addition, carrot peel powder retained high levels of total carotenoids, beta-carotene, lutein, and lycopene (Lau et al., 2018), which can be used as natural colourants to obtain optimal egg yolk color. However, despite the high levels of bioactive compounds, the bioavailability of carrot peel is still limited. To exert their uses in animal production, carrot peel needs to be processed, using different chemical or mechanical treatments. Regarding the latter, thermal drying is a postharvest technique to increase the shelf life of fruits or vegetables, preserving their quality and stability by reducing moisture content and water activity; thereby avoiding spoilage during storage (Zhang et al., 2017). During thermal processing, various biochemical reactions occur and produce components that may cause undesirable changes in the quality of carrot peel powder. To date, limited data are available on the carrot peel powder and no studies have addressed the use of the carrot peel powder, despite its impressive health benefits. Considering these facts, this present study aimed to investigate the effect of drying temperature on the yield and physico-chemical characteristics of the carrot peel powder. For such a goal, an ideal drying temperature for the convective drying process is announced to optimize the quality of the carrot peel powder.

Materials and Methods

Sample preparation

The experiment was conducted in the Central laboratory of An Giang University, Vietnam. Fresh carrot (Daucus carota L.) roots were purchased from a local market. The roots were kept in the refrigerator (2-4oC) in polyethylene bags until processed. The fresh carrot roots were washed thoroughly under running tap water to remove soil, dirt and other adhering particles before peeling with a hand peeler. To minimize adverse effects during the drying process and subsequent storage, the peels were pre-treated by soaking in a NaCl 5% solution for 2 min, followed by blanching in hot water (90oC) for 5 min. Then, the treated peels were drained to remove excess water. At this stage, after pre-treatments with salt solution and thermal blanching, the moisture contents of carrot peel samples were in the range of 90.1-91.9%.

Drying process

The carrot peels were equally divided into four portions and dried at 50, 60, 70, and 80oC (equivalent to four experimental treatments), under hot-air conditions in the Yamato DKN812 forced convection oven (Yamato Co., Ltd., Japan). About 300 g of the treated peels were evenly spread on a perforated wire tray (50×35 cm). For each drying treatment, samples were randomly collected from the dryer at thirty-minute intervals to be analyzed for moisture content. The drying process was continued until the moisture contents of the samples reached 5-7%, as suggested by Al-Amin et al. (2015). The drying time was recorded for each treatment using a timer. After drying, dehydrated peels were left cool, ground into powder through a 300 μm sieve, and kept in a ziplock bag at 2-4°C, maximum 20 days of storage to ensure their quality until analysis.

Analytical measurements

Peel to root ratio: Ten carrot roots were randomly selected to determine the fresh weight, using a 2-digit analytical balance. After peeling, the mass of the carrot peels was measured to calculate the peel ratio in the whole carrot root, expressed in percentage.

Drying yield: After drying, the dehydrated samples were reweighed to calculate their drying yield, using the following Equation 1.

Where; DY was the drying yield (%), DS was the weight of the dried sample (g), and FS was the weight of the fresh sample (g).

Proximate analysis

Samples of the fresh carrot peels and the peel powders were analyzed for dry matter, ash, protein, and fat according to the AOAC (2005) official standards. All chemical reagents were of analytical grade.

The detergent method (AOAC, 2005) was used for the determination of crude fiber with some modifications. One gram (1.0 g) of the carrot peel sample was taken into a volumetric flask followed by the addition of 100 mL of 0.255N H2SO4. The mixture was boiled for 10 min. and filtered through an ashless filter paper (Whatman No. 42). The residue was washed with 100 mL of 0.636N NaOH. The mixture was boiled for 10 min. and filtered as before. The residue was then washed with ethanol and ether to make it alkali-free. The residue was dried in an oven at 105oC until a constant weight was attained. The remaining residue after drying was taken as crude fiber.

For the determination of total carotenoid content, the carrot peel powder was extracted based on the method described by Lau et al. (2018). About 0.2 g of the sample was taken in a conical flask where acetone and hexane were added for extraction. The solution was then filtered and diluted to 100 mL. The total carotenoid content of the extract from carrot peel powder was determined using a UV-Visible spectrophotometer (Jasco V-730, Japan). The absorbance of hexane extract was measured at 436 nm against the blank. The total carotenoid content was calculated based on the standard curve of different carotenoid concentrations.

Water activity

The water activity (aw) of the samples was measured by a water activity meter (Aqualab 4TE, Addium Inc., USA) at room temperature (25±2°C).

Hydration properties

Water absorption (WAI) and water solubility (WSI) indices were determined following the procedures described by Nguyen et al. (2015) and Kaisangsri et al. (2016) with some modifications. One gram of the carrot peel powder was dispersed in 30 mL of distilled water in a 50-mL Falcon tube and mixed in a shaker (HS 260 basic shakers, IKA, Germany). The tubes were centrifuged at 45 rpm for 30 min. The supernatant was then carefully decanted and transferred to an aluminum dish and subsequently dried overnight at 105oC. The values of WAI and WSI were calculated using Equations 2 and 3, respectively.

WAI = wet sediment weight / dry sample weight …(2)

WSI = (dry supernatant 100) / dry sample weight …(3)

Colour measurements

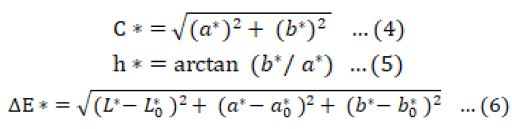

Colour measurements on fresh and powder samples were done using a Minolta chroma meter (Minolta, CR-400, Japan). The chroma meter was calibrated against a standard white reference tile D65 (L* = 94.20, a* = -0.02, and b* = 9.77) prior to sample measurements. The values of L* (lightness or luminance), a* (redness) and b* (yellowness) from the 3D colour space of CIELAB and CIELCH scales (CIE, 1978) were determined. Colour values of the samples were averages of 5 readings on different sites of the surface. The colour coordinates L*, a*, and b* were used to calculate the Chroma (C*, colour saturation), Hue angle (h*, colour tone), and total colour difference (ΔE*), using Equations 4, 5, and 6, respectively.

Where; L*0= 65.9 ± 0.19, a*0= 31.4 ± 0.29, and b*0= 46.9 ± 0.32 were the color values of the fresh carrot peel sample, expressed as references.

Statistical analysis

The experimental data subjected to analysis of variance and means were statistically analyzed using Minitab version 16.0 with a confidence level of 95%. The responses were physico-chemical characteristics and color parameters. An analysis of variance (ANOVA) was performed to determine the significant effect of drying temperature on the responses. All the analytical determinations were taken at least in duplicate. Pearson’s coefficients (r2) were used to investigate the relationship between drying temperature and dependent variables. Only correlation coefficients with p<0.05, indicating the statistical significance, were shown.

Results and Discussion

Peel to root ratio

Peeling is an important unit operation to remove the outer layer of many root vegetables in order to produce fresh-cut for subsequent processes (Li, 2020). Weights of the whole root 229±19.6 g and the peel 26.9±2.92 g. The peel to root ratio was 11.8±1.23. Conversa et al. (2022) also found that the peels of the Presto carrot (commercial hybrid genotype) accounted for 11% of the total biomass of the fresh carrot root. According to Nguyen and Scarlett (2016), the mass proportion of heads and peels accounted for 5.01% and 14.2% of root biomass, by fresh weight, indicating that the peel was a main waste from carrot processing.

Drying time and drying yield

Table 1 shows the results of drying time, residual moisture and drying yield of carrot peel samples under four conditions of drying temperature. As expected for hot-air drying, there was a gradual reduction in the dehydration time with the increase in drying temperature, a general phenomenon reported for residues of fruit and vegetables, such as dragon fruit peels (dos Santos et al., 2017), gac peels (Hoang et al., 2017), and potato peels (Brahmi et al., 2023).

Table 1: Effect of drying temperature on the drying time and drying yield of carrot peel powders.

|

Parameter |

Drying temperature (oC) |

SEM |

p |

|||

|

50 |

60 |

70 |

80 |

|||

|

Drying time (min.) |

360 |

300 |

240 |

180 |

- |

- |

|

Moisture content (%) |

6.12 |

5.50 |

6.47 |

6.47 |

0.21 |

0.083 |

|

Drying yield (%) |

10.6a |

9.90b |

9.93b |

9.86b |

0.10 |

0.019 |

Values with different superscript letters in the same row are significantly different (p<0.05).

Drying time was strongly affected by temperature, ranging from 180 min to 360 min. The initial moisture content of the carrot peel prior to drying was 91.3±0.82% and the time required to reach the moisture content of 5-7% was 360, 300, 240, and 180 min at the temperatures of 50, 60, 70, and 80°C, respectively (Table 1). Compared with dying time at 50oC, a 25-50% reduction was obtained from drying at 60 to 80°C, meaning that the drying time was reduced by more than 50% when the temperature increased from 50°C to 80°C.

From Figure 1, there was a reduction in the moisture content with the increase in drying temperature as evaporation is faster at the higher temperature. The drying time in this study was shorter than that in the research of Nguyen and Le (2018) when using hot-air drying at 50oC and 100oC. This finding is in agreement with the study of Kumar et al. (2012), who reported that, within a certain range of 60-75°C, increasing temperature sped up the evaporation process and shortened the drying time. Similar results were also found for other fruit and vegetable products, such as mango leather (Guarte et al., 2005), dragon fruit peel (dos Santos et al., 2017), orange peel (Manjarres-Pinzon et al., 2013) and Moringa leaf (Nguyen and Le, 2021).

Regarding residual moisture, it was notable that the final moisture of the peel samples was not significantly different (p>0.05). In the range of 5.50-6.47%, the moisture contents of the carrot peel powders were close to the result found by Nguyen and Le (2018). These values were found to be in the acceptable range of less than 14% as per the norms of Vietnamese National Standards issued for animal feeding stuffs.

As shown in Table 1 and Figure 1, the drying yield decreased with an increase in drying temperature. The highest drying yield was obtained at 50oC (10.6% or 10.6 g dry sample/100 g fresh sample), which was significantly different from the other drying temperatures (p<0.05). The drying yields obtained in this research were higher than the value (9.60%) reported by Nguyen and Le (2018), with similar drying condition (50oC) for carrot peels. Overall, the different drying temperature led to the differences in the drying yield of carrot peels. Of these, drying at 50oC had the slowest but highest yield of dried carrot peels.

Functional properties

Water is the major component in most plant materials and the physical properties of water have a significant influence on the quality of powder during processing, and storage (Zhang et al., 2017). Table 2 shows the significant effect (p<0.05) of drying temperature on the physical properties of carrot peel powder. The water activity of dried samples was found to be in the range of 0.38-0.42 (Table 2) and significantly different among the treatments (p<0.05). However, the effect of drying temperature on this indicator was unclear. The variations of water activity might be due to the considerable losses in the moisture content during the drying process. Similar to the moisture content, the water activity of carrot peel powders was within an acceptable range for dried samples. According to Manjarres-Pinzon et al. (2013), reducing aw below 0.6 could prevent microbiological spoilage; but other chemical reactions, such as enzymatic activity, non-enzymatic browning, and lipid oxidation, could be prevented with aw values around 0.3 considered to extend the shelf life and stability during storage.

Table 2: Effect of drying temperature on the functional properties and chemical composition of carrot peel powders.

|

Parameter |

Drying temperature (oC) |

SEM |

p |

|||

|

50 |

60 |

70 |

80 |

|||

|

aw |

0.39b |

0.41ab |

0.42a |

0.38b |

0.00 |

0.013 |

|

WAI |

19.1b |

22.3a |

22.6a |

22.1a |

0.48 |

0.019 |

|

WSI |

11.4b |

10.6b |

14.0ab |

16.9a |

0.77 |

0.014 |

|

Dry matter (%) |

93.9 |

94.5 |

93.5 |

93.5 |

0.21 |

0.083 |

|

Ash (%) |

10.0c |

11.9b |

12.4a |

10.0c |

0.05 |

0.000 |

|

Crude protein (%) |

7.03a |

5.24b |

4.27c |

3.69c |

0.12 |

0.000 |

|

Crude fat (%) |

1.31b |

1.35a |

1.33ab |

1.30b |

0.01 |

0.018 |

|

Crude fiber (%) |

7.70 |

7.44 |

6.63 |

6.72 |

0.30 |

0.145 |

|

Total carotenoids (ug/g dry weight) |

713a |

253b |

89.5c |

82.1c |

11.7 |

0.000 |

Values with different superscript letters in the same row are significantly different (p<0.05).

The physical properties of plant materials depend on diverse particle sizes, structures of the polysaccharides and processing conditions. Particularly, during the thermal process, there were changes in the chemical composition including starch, protein, soluble, and insoluble dietary fibers, which can be measured by hydration properties, as indicators of molecular degradation (Zhang et al., 2017). The WAI exhibits the ability of the materials to absorb water, while the WSI represents the ability of powder to dissolve in water. In this study, significant differences (p<0.05) in WAI and WSI were shown among the treatments (Table 2). The WAI was in the range of 19.1-22.6, and increased with drying temperature. Such a phenomenon could be due to the higher water absorption capability of the fiber content in carrot peel powders. The WSI ranged from 10.6 to 16.9 and the maximum WSI was recorded in the sample dried at 80°C. In line with the WAI, the WSI significantly increased with a decrease in drying temperature (p<0.05).

Chemical composition

Ash is an important nutrient and inorganic residue after combustion at high temperature. The ash content of carrot peel powders was in the range of 10.0-12.4%, higher than that of the fresh carrot (8.29±0.29%), partly due to the mineral absorption during soaking in salt solution. The ash content in the carrot peels was significantly affected by the drying temperature (p<0.05). The crude protein content of the fresh carrot peel used in this study was 3.48±0.04%. After drying, the highest protein content (7.03%) was found for the carrot peel powder subjected to the drying temperature 50oC, and the lowest protein content (3.69%) was recorded for the sample subjected to the highest drying temperature (80℃). This downward trend could be due to the leaching of some water-soluble and salt-soluble proteins in the pre-treatment stage. The hot-air drying conditions may also result in the loss of heat-sensitive proteins or protein denaturation which contributed to the reduction of protein content at high drying temperature (Agiriga et al., 2015). The thermal treatments significantly (p<0.05) affected the fat content of the carrot peels (Table 2). However, the mean values of fat content just varied in a narrow range of 1.30-1.35% and no trend was observed. The crude fiber content of the carrot peel powders ranged from 6.63% to 7.70% but the difference was non-significant (p>0.05), as shown in Table 2. It revealed that different drying temperatures had no effect on the fiber content of the carrot peel samples.

In terms of bioactive compounds, orange carrot is rich in carotenoids, comprising three carotenes (alpha-carotene, beta-carotene, and lycopene) and three xanthophylls (lutein, zeaxanthin, and beta-cryptoxanthin). However, during processing, up to 50% of the carotenoid content was lost (Seregelj et al., 2021). Table 2 presents the total carotenoid content of the carrot peel powders, exhibiting the significant (p<0.05) impact of the heat treatment. The highest value of total carotenoid content (713 ug/g dry weight) was observed in the sample dried at 50°C, and the lowest level of carotenoids (82.1 ug/g dry weight) was noted in the sample dried at 80°C. This finding could be explained by thermal degradation induced by the increased drying temperature from 50oC to 80oC. In addition, hot-air drying may disrupt the cell membrane, causing the release of carotenoids, the most important water-insoluble pigments in carrot root (Agiriga et al., 2015). Guarte et al. (2005), however, found that increased beta-carotene losses were associated with lower temperatures and longer exposure to heat.

In general, to preserve nutrients and minimize the loss of bioactive compounds, fruits and vegetables need to be dried at a lower temperature (Manjarres-Pinzon et al., 2013; dos Santos et al., 2017; Brahmi et al., 2023). In this study, the temperature of 50°C would be the most adequate for carrot peel drying, as it retains higher content of carotenoids, which highlights its potential use as a natural colourant in the food and feed industry.

Colour coordinates

Colour is an important sensory attribute, reflecting the quality of the dried products that affects consumer acceptance and preference. The colour parameters and visual characteristics of the carrot peel powders are shown in Table 3 and Figure 2. The results showed that drying temperatures possessed had a significant impact on the CIE L*a*b* coordinates, as did the Chroma (C*), hue (h*), and total colour difference (ΔE*) (p < 0.05). It revealed that temperatures might affect the carotenoids, the major pigment in the carrot peels.

The L* values of peel powders were found in the range of 63.6-66.1, while the a* values were in the range of 19.4-25.7, and the b* values were in the range of 35.3-38.5, classified as reddish. Compared with the fresh carrot peels, little change in L* value was found but there were significant losses of a* and b* values, indicating a reduction in the redness and yellowness, probably due to the degradation of carotenoid pigments during the drying process. Within the experimental treatments, general decreasing trends were observed in a*and b* values, as a result of an increase in drying temperature (p<0.05). However, under the same conditions, a notable increase in the L* value was noted. It showed that the higher the L* values, the lighter the peel powders were observed, while the higher values of a* and b* indicated more retention of red and yellow colours in the final products. From the current findings, it revealed that despite longer time exposure to heat, the sample dried at 50oC possessed the lower values of L*, h*, and ΔE* but the higher values of a*, b*, and C*, compared to other thermal treatments.

Table 3: Effect of drying temperature on the colour of carrot peel powders.

|

Parameter |

Drying temperature (oC) |

SEM |

p |

|||

|

50 |

60 |

70 |

80 |

|||

|

L* |

63.6b |

65.1a |

64.9a |

66.1a |

0.30 |

0.000 |

|

a* |

25.7a |

24.2b |

22.6c |

19.4d |

0.24 |

0.000 |

|

b* |

38.5a |

37.4b |

35.9c |

35.3c |

0.27 |

0.000 |

|

C* |

46.3a |

44.6b |

42.4c |

40.2d |

0.27 |

0.000 |

|

h* |

0.98c |

1.00bc |

1.01b |

1.07a |

0.01 |

0.000 |

|

ΔE* |

10.4d |

12.0c |

14.2b |

16.8a |

0.26 |

0.000 |

Values with different superscript letters in the same row are significantly different (p<0.05).

The C* value (the Chroma or colour saturation indicates the purity or intensity of the colour) was found in the range of 40.2-46.3. Statistical analysis showed that the drying temperature significantly affected this colour parameter (p<0.05). Drying contributed to the weakening of the colour intensity of the dried peels compared to the fresh peels, with a value of 56.4±0.42. The colour tones (h*) of the dried carrot peel powders ranged from 0.98 to 1.07, with a predominance of intense red colour. The total colour difference corresponding to the colour distance from the fresh carrot peels, ΔE*, ranged from 10.4 to 16.8 (Table 3). Statistical analysis showed that the ΔE* values were significantly different (p<0.05) with an upward trend. The greatest difference was found in samples dried at 80oC (possibly due to high pigment degradation) and the smallest difference was noted in samples dried at 50oC. This indicated that thermal treatment at 50oC could be better to retain the colour of the fresh carrot peels. Similar findings were also found by Zheng et al. (2023) and Dhake et al. (2023), who reported that lower drying temperatures could improve colour quality of food and vegetable products. From the literature review, the breakdown of pigments, polyphenol oxidation, along with non-enzymatic browning reactions, including caramelization and the Maillard reaction taking place during the drying process, all may contribute to the colour changes of dried fruits and vegetables (dos Santos et al., 2017; Zhang et al., 2017).

The relationship between drying temperature and other experimental parameters

Pearson’s correlations (r2) between drying temperature and other experimental parameters are shown in Table 4. The coefficients with r2 < 1.0 showed negative correlations between drying temperature and drying time as well as crude protein content and some colour attributes (a*, b*, and C*) of the carrot peel powders. Conversely, a positive correlation (r2 = 0.99; p = 0.006) was observed between drying temperature and total colour differences (ΔE*) of the carrot peel powders.

Table 4: Pearson’s correlations between drying temperature and other experimental parameters.

|

Parameters |

r2 |

p |

|

Drying time |

-1.00 |

0.000 |

|

Crude protein |

-0.97 |

0.030 |

|

a* |

-0.98 |

0.021 |

|

b* |

-0.99 |

0.012 |

|

C* |

-1.00 |

0.001 |

|

ΔE* |

0.99 |

0.006 |

In our case, these findings suggested that increasing drying temperature (from 50oC to 80oC) applied for the carrot peels significantly increased the differences from the original colour but reduced the drying time, crude protein content, redness, and yellowness of the dried powders. Similar behavior was reported previously by Shuen et al. (2021), in which drying temperature had a negative correlation with the retention of colour pigments and antioxidant content of the wild mango (Mangifera odorata Griff.) powder.

Conclusions and Recommendations

This study presented a comparative analysis of the physico-chemical properties of the carrot peel powders obtained from hot-air drying. Different temperatures during convective drying significantly affected the drying time, drying yield, and most of the physico-chemical properties, particularly the total carotenoids of the carrot peel powders. Optimal conditions for hot-air drying of the carrot peels were 50°C for 360 min. Overall, it can be stated that the carrot peel powder is a value-added product of carrot production that can act as a natural bio-colorant in the food-feed systems.

Acknowledgement

This research is funded by An Giang University (AGU), Vietnam National University Ho Chi Minh City (VNU-HCM) under grant number C2023-16-09. The support and encouragement from our colleagues are also worth mentioning.

Novelty Statement

Different hot-air drying temperatures were applied for the carrot peel and comparative analysis based on the physico-chemical properties of the powder are discussed in detail.

Author’s Contribution

Nguyen Tuyet Giang: Conceived, wrote original draft and revised the manuscript.

Le Thi Thuy Hang: Carried out lab experiments and data collection.

Phan Phuong Loan: Analyzed of data.

Le Thi Thuy Loan: Verified the analytical methods and interpreted data.

All authors provided critical feedback and approved the final version of the manuscript.

Conflict of interest

The authors declare no conflict of interest.

References

Agiriga, A.N., M.O. Iwe, U.J. Etoamaihe and O.A. Olaoye. 2015. Impact of different blanching treatments on the nutritional and sensory properties of oven dried carrot slices. Sky J. Food Sci., 4(7): 102-107.

Ahmad, T., M. Cawood, Q. Iqbal, A. Ariño, A. Batool, R.M.S. Tariq, M. Azam and S. Akhtar. 2019. Phytochemicals in Daucus carota and their health benefits. Review article. Foods, 8: 1-22. https://doi.org/10.3390/foods8090424

Al-Amin, M., M.S. Hossain and A. Iqbal. 2015. Effect of pre-treatments and drying methods on dehydration and rehydration characteristics of carrot. Univers. J. Food Nutr. Sci., 3(2): 23-28. https://doi.org/10.13189/ujfns.2015.030201

Amin, S., S. Jung, I. Kang and A. Duval. 2021. Valorization of baby carrot processing waste. J. Culin. Sci. Technol., 21(1): 1-17. https://doi.org/10.1080/15428052.2021.1879338

Amran, M.A., K. Palaniveloo, R. Fauzi, N.M. Satar, T.B.M. Mohidin, G. Mohan, S.A. Razak, M. Arunasalam, T. Nagappan and J.S.S. Seelan. 2021. Value-added metabolites from agricultural waste and application of green extraction techniques. Sustainability, 13(20): 11432-11459. https://doi.org/10.3390/su132011432

AOAC, 2005. Official methods of analysis of AOAC international-18th edition. Horwitz, W. (Ed.). Association of Official Analytical Chemists. Washington DC, USA.

Brahmi, F., I. Mateos-Aparicio, K. Mouhoubi, S. Guemouni, T. Sahki, F. Dahmoune, F. Belmehdi, C. Bessai, K. Madani and L. Boulekbache-Makhlouf. 2023. Kinetic modeling of convective and microwave drying of potato peels and their effects on antioxidant content and capacity. Antioxidants, 12: 1-18. https://doi.org/10.3390/antiox12030638

CIE, 1978. International commission on illumination, recommendations on uniform color spaces, color difference equations, psychometric color terms. Supplement No. 2 to C.I.E. publication No. 15 (E-1.3.1) 1971/ (TC-1.3) 1978. Bureau Central de la C.I.E., Paris, France.

Conversa, G., A. Bonasia, G. Natrella, C. Lazzizera and A. Elia. 2022. Peeling affects the nutritional properties of carrot genotypes. Foods, 11: 1-15. https://doi.org/10.3390/foods11010045

de Oliveira, S.W.R., R.M.F. de Figueirêdo, A.J. de Melo Queiroz, F.S. dos Santos, A.P. de França Silva, Y.F. Paiva, H.V. Moura, E.T. de Vilela Silva, A.J. de Brito Araújo Carvalho, M. dos Santos Lima, A.R.N. Campos, M.G. Gregorio and A.G.B. de Lima. 2023. Effect of drying temperature on antioxidant activity, phenolic compound profile and hygroscopic behavior of pomegranate peel and seed flours. LWT Food Sci. Technol., 189: 1-9. https://doi.org/10.1016/j.lwt.2023.115514

Dhake, K., S.K. Jain, S. Jagtap and P.B. Pathare. 2023. Effect of pretreatment and temperature on drying characteristics and quality of green banana peel. Agric. Eng., 5: 2064-2078. https://doi.org/10.3390/agriengineering5040127

dos Santos, F.S., R.M.F. de Figueirêdo, A.J. de M Queiroz and D.C. Santos. 2017. Drying kinetics and physical and chemical characterization of white-fleshed ‘pitaya’ peels. Rev. Bras. Eng. Agric. Ambient., 21(12): 872-877. https://doi.org/10.1590/1807-1929/agriambi.v21n12p872-877

FAO, 2019. The state of food and agriculture. In: Moving forward on food loss and waste reduction. Rome: FAO.

FAOSTAT, 2021. Crops and livestock products. https://www.fao.org/faostat/en/#data/QCL.

Gowe, C. 2015. Review on potential use of fruit and vegetables by-products as a valuable source of natural food additives. Food sci. qual. manag., 45: 47-61.

Guarte, R.C., I. Pott and W. Mühlbauer. 2005. Influence of drying parameters on β-carotene retention in mango leather. Fruits, 60: 255-265. https://doi.org/10.1051/fruits:2005032

Hoang, V.C., P.D. Roach, J.B. Golding, S.E. Parks and M.H. Nguyen. 2017. Effects of pretreatments and air drying temperatures on the carotenoid composition and antioxidant capacity of dried gac peel. J. Food Process. Preserv., 41(6): 1-9. https://doi.org/10.1111/jfpp.13226

John, S., S. Priyadarshini, S.J. Monica, C. Sivaraj and P. Arumugam. 2017. In vitro evaluation of antioxidant and antimicrobial activity of carrot peel. Int. J. Pharmacogn. Phytochem. Res., 9(7): 970-974. https://doi.org/10.25258/phyto.v9i07.11165

Kaisangsri, N., R.J. Kowalski, I. Wijesekara, O. Kerdchoechuen, N. Laohakunjit and G.M. Ganjyal. 2016. Carrot pomace enhances the expansion and nutritional quality of corn starch extrudates. LWT Food Sci. Technol., 68: 391-399. https://doi.org/10.1016/j.lwt.2015.12.016

Kaur, G.J., D. Kumar, V. Orsat and A. Singh. 2022. Assessment of carrot rejects and wastes for food product development and as a biofuel. Biomass Convers. Biorefin., 12(1): 757-768. https://doi.org/10.1007/s13399-020-01096-z

Krivokapić, S., T. Pejatović and S. Perović. 2020. Chemical characterization, nutritional benefits and some processed products from carrot (Daucus carota L.). Agric. For., 66(2): 191-216. https://doi.org/10.17707/AgricultForest.66.2.18

Kumar, N., B.C. Sarkar and H.K. Sharma. 2012. Mathematical modelling of thin layer hot-air drying of carrot pomace. J. Food Sci. Technol., 49(1): 33-41. https://doi.org/10.1007/s13197-011-0266-7

Lau, W.K., V.C. Hoang and Q.V. Vuong. 2018. Physical properties, carotenoids and antioxidant capacity of carrot (Daucus carota L.) peel as influenced by different drying treatments. Int. J. Food Eng., 2018: 1-13. https://doi.org/10.1515/ijfe-2017-0042

Li, X., 2020. Methods of peeling fruits and vegetables. In: Handbook of food preservation. Rahman, M.S. (eds). CRC Press. https://doi.org/10.1201/9780429091483-4

Manjarres-Pinzon, K., M. Cortes-Rodriguez and E. Rodríguez-Sandoval. 2013. Effect of drying conditions on the physical properties of impregnated orange peel. Braz. J. Chem. Eng., 30(3): 667-676. https://doi.org/10.1590/S0104-66322013000300023

Nguyen, G.T., M.J. Gidley and P.A. Sopade. 2015. Dependence of in-vitro starch and protein digestions on particle size of field peas (Pisum sativum L.). LWT Food Sci. Technol., 63: 541-549. https://doi.org/10.1016/j.lwt.2015.03.037

Nguyen, T.G. and T.T.H. Le. 2021. Effect of drying temperature on physicochemical properties of Moringa oleifera leaf. Livest. Res. Rural. Dev., 33(11).

Nguyen, V.T. and C.J. Scarlett. 2016. Mass proportion, bioactive compounds and antioxidant capacity of carrot peel as affected by various solvents. Technologies, 4: 1-13. https://doi.org/10.3390/technologies4040036

Nguyen, V.T. and M.D. Le. 2018. Influence of various drying conditions on phytochemical compounds and antioxidant activity of carrot peel. Beverages, 4: 1-12. https://doi.org/10.3390/beverages4040080

Reduron, J.P., 2021. Taxonomy, origin and importance of the Apiaceae family. In: Carrots and related Apiaceae crops 2nd edition. Geoffriau E, and Simon P W (eds). CAB International. https://doi.org/10.1079/9781789240955.0001

Seregelj, V., J. Vuliic, G. Cetkovic, J. Canadanovc-Brunet, V.T. Saponjac and S. Stajecic. 2021. Natural bioactive compounds in carrot waste for food applications and health benefits. in: studies in natural products chemistry. Elsevier Inc. https://doi.org/10.1016/B978-0-12-819483-6.00009-6

Sharma, K.D., S. Karki, N.S. Thakur and S. Attri. 2012. Chemical composition, functional properties and processing of carrot. A review. J. Food Sci. Technol., 49(1): 22-32. https://doi.org/10.1007/s13197-011-0310-7

Shuen, G.W., L.Y. Yi, T.S. Ying, G.C.Y. Von, Y.A.B. Yusof and P.L. Phing. 2021. Effects of drying methods on the physicochemical properties and antioxidant capacity of Kuini powder. Braz. J. Food Technol., 24: 1-14. https://doi.org/10.1590/1981-6723.08620

Thiviya, P., N. Gunawardena, A. Gamage, T. Madhujith and O. Merah. 2022. Apiaceae family as a valuable source of biocidal components and their potential uses in agriculture. Horticulturae, 8(7): 1-32. https://doi.org/10.3390/horticulturae8070614

Zhang, M., H. Chen, A.S. Mujumdar, J. Tang, S. Miao and Y. Wang. 2017. Recent developments in high-quality drying of vegetables, fruits, and aquatic products. Crit. Rev. Food Sci. Nutr., 57(6): 1239-1255. https://doi.org/10.1080/10408398.2014.979280

Zheng, Z., S. Wang, C. Zhang, M. Wu, D. Cui, X. Fu, L. Gao, A. Li, Q. Wei and Z. Liu. 2023. Hot-air impingement drying enhanced drying characteristics and quality attributes of Ophiopogonis radix. Foods, 12: 1-14. https://doi.org/10.3390/foods12071441

To share on other social networks, click on any share button. What are these?