Performance Evaluation of New Rotary Blades and Roller Cutter of Versatile Multi-Crop Planter on Residue Management

Research Article

Performance Evaluation of New Rotary Blades and Roller Cutter of Versatile Multi-Crop Planter on Residue Management

Abdullah Al Musabbir1, Md Abedur Rahman2*, Naveed Anjum2, 3 and Mustajab Ali4,5

1Department of Farm Power and Machinery, Bangladesh Agricultural University, Mymensingh 2202, Bangladesh; 2Graduate School of Science and Engineering, Saitama University, Saitama 338-8570, Japan; 3Department of Civil Engineering, Khwaja Fareed University of Engineering and Information Technology, Rahim Yar Khan 64200, Pakistan; 4Department of Civil Engineering, Mirpur University of Science and Technology, Mirpur AJK 10250, Pakistan; 5Department of Civil Engineering, The University of Tokyo, Tokyo 113-8656, Japan.

Abstract | The present study clarified the effectiveness of rotary blades and roller cutters on residue management in the planter. A new rotary blade (Blade B) along with roller cutter was designed and their effect on the residue management was investigated. However, to justify the effectiveness of newly designed rotary blade, the traditional blade (Blade A) was also considered in addition to Blade B. Experimental results showed that the straw accumulation in strip tillage in anchored residues by using Blade A in straw heights of 20, 30, and 40 cm was found to be 9.03%, 10.36%, and 12.14%, respectively. Whereas, these were 6.50%, 8.74%, and 8.88% for the corresponding straw heights, which were 28.01%, 16.63% and 26.85% lower, respectively while using Blade B. In both anchored and loose straw conditions, the effective field capacity was witnessed to be higher for Blade B. Furthermore, a significant reduction in the percentage of time loss in strip tillage was observed by using Blade B compared to that of the Blade A in all considered cases. Thus, Blade B was found to be better in strip tillage system in both anchored and loose residues in the field compared to Blade A. However, due to additional accumulated straws in the furrow opener and the excessive weight of the roller cutter in the tillage process, it is recommended to use rotary Blade B in the rotary shaft with anchored condition for the better management of residues and in order to obtain effective crop production.

Received | December 03, 2021; Accepted | June 09, 2022; Published | December 01, 2022

*Correspondence | Md Abedur rahman, Graduate School of Science and Engineering, Saitama University, 255 Shimo-Okubo, Sakura-Ku, Saitama-Shi, Saitama 338-8570, Japan; Email: [email protected]

Citation | Al-Musabbir, A., M.A. Rahman, N. Anjum and M. Ali. 2022. Performance evaluation of new rotary blades and roller cutter of versatile multi-crop planter on residue management. Sarhad Journal of Agriculture, 38(5): 211-221.

DOI | https://dx.doi.org/10.17582/journal.sja/2022/38.5.211.221

Keywords | Rotary blade, Roller cutter, Design and development, Straw accumulation, Time loss

Copyright: 2022 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

The increasing human population poses a difficult challenge for the agricultural systems to meet up and maintain food security (Molotoks et al., 2020). Besides abundant natural resources like solar radiation (Ali and Kim, 2021), moderate temperatures and plenty of rainfall (Ali, 2021), still it is hard for South Asian developing countries to meet their water and agricultural food demands (Rahman and Hasan, 2016; Gregorio and Ancog, 2020). In recent times, conservation agricultural practices (CA) are being considered as most effective measures for the crop production. These can be defined as the combination of three major farming principles needed for successful crop production with the latest technologies, i.e., minimum soil disturbance, crop residue management and crop rotation (Chabert and Sarthou, 2020). CA consists of four types of minimum tillage system i.e. Single pass shallow tillage (SPST), Zero tillage (ZT) Strip tillage (ST), and Bed planting (BP). In addition, this CA system also has some potential benefits such as increased yield (Celik and Altikat, 2010), reduced operational cost including machinery, labor, fuel with a better utilization of natural resources (Tabriz et al., 2021).

Crop residue is the materials left in an agricultural field after the crop is harvested. It includes stalks and stubble (stems), leaves and seed pods. Residues management covers reducing particulate matter emissions and wind erosion by maintaining a minimum of 60 percent ground cover of crop and other plant residues on a soil surface between the time of crop harvest and the commencement of tillage for a new crop. This improves soil properties and organic compositions (Mondal et al., 2004) in addition to the improvements in the physical, chemical and biological properties of the soil (Sidhu and Beri, 2008). These soil conservation techniques also offer to a reduction in fertilizer dependency for crop production (Bird et al., 2001) and leads to a sustained and improved crop yield (Badarinath et al. 2006).

Conventional tillage practice and hand broadcasting of seed and fertilizer is a laborious and time-consuming operation (Tabriz et al., 2021). The application of machines to agricultural production has been one of the outstanding developments in recent period of times (Banerjee and Punekar, 2020; Sanaullah et al., 2021) which covers around 80% of the agricultural activities (Valin et al., 2013). Two wheeled tractors operated in CA based tillage technology have been developed and promotional activities are being conducted in the farmer’s field of Bangladesh. They provide an insight of crop yield gap minimization, water saving, efficient input utilization, soil health improvement, sustainable crop production and crop diversification (Loon et al., 2020). However, the rapid spread of mechanization in small farms in Asia has not yet led to the development of a range of low-cost planters for two-wheeled tractors that can be used for minimum tillage (Baudron et al., 2015). For example, two-wheeled tractors are comparatively cheap and easily maneuverable in lands with small slopes even in the presence of trees in the field. These machines have been adopted at large scale as they have advantages over four-wheeled tractors as well as animal traction in terms of operational costs, less emissions (Baudron et al., 2015) and fewer soil compactions due to their small weight. Hence, versatile multi-crop planter (VMP) was developed to perform minimum tilling, direct seed sowing and fertilizer application in line simultaneously for a diverse crop range in CA system. Using VMP machine also saves seed and fertilizer as compared to conventional system by ensuring the optimum use of seed and fertilizer. The initial two wheeled tractor based on the VMP developments with ZT, SPST (up to 60 mm deep), ST, and BP, in Bangladesh were reported by Gregg et al. (2020). The field capacity of VMP in the four-tillage system was found to be 40-57% higher than that of the conventional tillage systems and the land preparation cost by VMP also decreased by ~75% (Haque and Bell, 2017). Machine sowing permits crops to take advantage of residual moisture in crop fields which also facilitates the irrigation practices. Regardless of tillage treatment, a reduced amount (41-43%) of irrigation water is used by crops established by VMP planting operation as compared to conventional tillage system (Islam et al., 2010). Hence, the usage of VMP machines is unavoidable for agriculture these days.

At the initial stage of VMP development some mechanical faults were found during field testing of the machine (Tabriz et al., 2021). Therefore, an extra gear box was needed to attach the machine with a power tiller which increased the total length of the machine and the turning radius. However, such arrangements have imbalanced the VMP due to the excessive weight causing difficulty in the operation. However, some of the problems were eliminated by removing press wheels, extra gear box and round rotary shaft (Haque et al., 2011). Even after the improvement of the machine, the accumulation of straw in the furrow opener and in the rotary shaft of the machine during field operation with different straw heights in both ZT and ST systems is still unsolved (Tabriz et al., 2021). CA technologies especially ZT and ST are more viable in drought stress areas where seeding operation and initial plants establishment can be done utilizing the residual soil moisture available immediately after monsoon rice harvest. This also significantly affects water demand of the dry season rice varieties (Rahman et al., 2015, 2019, 2022).

Minimum tillage and residue retention improves some of the soil physical properties including the bulk density, volumetric water content, porosity, and penetration resistance in rice-maize cropping system in addition to higher yields (Hossain et al., 2015). Also, the minimum tillage and residue retention enhances the soil fertility by increasing the organic matters, potassium, phosphorus, and nitrogen etc., (Martín-Lammerding et al., 2021). However, the heights of the residue are still a problem for the roller cutter for planter operation. In addition, the strips made by the rotary blades and the roller cutter will facilitate the irrigation practices by conserving soil moisture. Such increase in crop yields by improving agricultural machinery design has also been confirmed by past researchers (Huang et al., 2018; Tang et al., 2018; Jahun et al., 2020). However, little research has been conducted to determine suitable design of a rotary blade and a roller cutter of VMP. Thus, improvements and re-evaluation in the performance of VMP at different straw heights in the farmer’s fields was essential to carry out. The objectives of this study were to:

- Design a new rotary blade, and a roller cutter of VMP.

- Demonstration of the effects of newly designed rotary blade and a roller cutter of VMP at different straw heights for a better residue management.

To clarify the significances of the newly designed rotary blade, Blade A (existing blade) was also considered for the comparison purposes.

Materials and Methods

In the field experiment, the VMP shown in Figure 1 was tested in different straw heights for crop residue management. A 12 hp (1.5 kW) Dongfeng Power Tiller was used as a prime mover for VMP. The functional parts of VMP are toolbar frame, seed metering device, seed and fertilizer box, seed and fertilizer adjusting lever, furrow opener, furrow closer, depth control device, and chain sprocket. In the present study, two different types of blade (i.e. Blade A and Blade B) were used at four different straw heights (i.e. 0 cm, 20cm, 30cm and 40cm). Each case was repeated for three times with both anchored and loose straw conditions.

Design procedures

Design of roller cutter: The roller cutter (Figure 2) made of steel with a dimension of 1.2 m in width, thickness of each blade of roller cutter is 2.5mm with a rotary shaft of 5 cm (diameter), making total diameter of 14 cm including tine holder, and a circular diameter of 0.39 m was adopted. It consisted of 4 identical cutters with 26 spike teeth per cutter (Figure 2B and C). Roller cutter was inserted in place of a rotary shaft within the VMP in Zero tillage system for cutting straw before the furrow opener passes through it.

Design of rotary blade: The considered rotary Blade was made of mild steel with a thickness of 4 mm (each blades). It is used in tillage operations for making strips in the soil. Existing rotary blade was termed as Blade A (Figure 3) and edge curve angle of this blade is 41°.The angle (α) in a rotary blade between the radius direction of the turning Blade and the tangential line of its edge-curve is the main factor to be considered in designing the blade. When α is small, the length wise portion of the blade becomes straight and easily hooks the grass and straw. On the contrary, when α is large, the grass and straw easily slip off the blade. Moreover, if α is large, the area of the blade which goes into the soil is wide, which means there will be higher frictional area between the soil and blade which will result in a higher tilling resistance. Cutting angle of the time is shown in Figure 4.

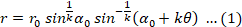

This rotary blade is designed according to the equation from some design knows hows of edge curve angle of rotary blades for paddy cultivation (Sakai, 1977) given below:

Where ro =0.2 m, k = 1/9, α0= 57.50

In this equation, by putting θ from 0-90° get this edge curve where α is increasing with the increase of θ and this variation is represented in Figure 4. The newly designed rotary blade is termed as Blade B with an edge curve angle of 57.50°, and tip angle of 45° (Figure 5). The detail of curvature of the proposed blade B (Figure 6A and B) is shown in Table 1.

Table 1: Tine angles/curvature of proposed blade (blade B).

|

S. no. |

α0 |

r0 |

k |

θ |

r |

|

1 |

57.5 |

20 |

1/9 |

10 |

17.94 |

|

2 |

57.5 |

20 |

1/9 |

20 |

16.17 |

|

3 |

57.5 |

20 |

1/9 |

30 |

14.63 |

|

4 |

57.5 |

20 |

1/9 |

40 |

13.3 |

|

5 |

57.5 |

20 |

1/9 |

50 |

12.15 |

|

6 |

57.5 |

20 |

1/9 |

60 |

11.14 |

|

7 |

57.5 |

20 |

1/9 |

70 |

10.26 |

|

8 |

57.5 |

20 |

1/9 |

80 |

9.48 |

|

9 |

57.5 |

20 |

1/9 |

90 |

8.81 |

Land preparation

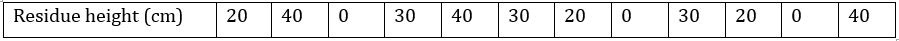

For this experiment, residue was cut at four different heights i.e. 0, 20, 30, and 40 cm. This process was done on a random basis, and after cutting, the residues were kept anchored in the field. Thus, 12 blocks were made in the field, where 3 of these blocks had the same residue height. The area of each block was 17×0.8 m2. The layout of the field is shown below:

Again, the residue was cut at four different heights (0, 20, 30, and 40 cm) in the same way in 12 blocks, but this time the residue was kept loose in the field and area of each block was 15×0.8 m2.Thus, the area was different in the both anchored and loose residue fields. Planter was tested in both conditions of anchored residue and loose residue in the field.

Blade A arrangement

Blade A arrangement of planters in Strip tillage (ST) and Zero tillage (ZT) mode is given in (Figure 7). Two types of blades and 16 blades were used in this experiment in a strip tillage system.

Theoretical procedures

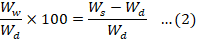

Soil and residue sample: Soil samples were collected randomly to determine the physical properties of soil. Oven dry method was followed to determine the moisture content and is represented by the following equation by Gupta and Larson (1979):

Where; Ww is the weight of water, Ws is the weight of wet soil samples, and Wd is the weight of dried soil samples. The same procedure has been followed for the determination of moisture content (dry basis) of residue.

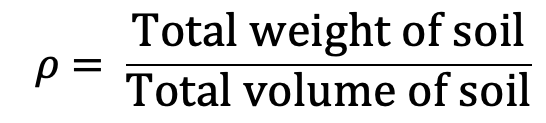

The bulk density (ρ, g/cm3) f the soil samples was estimated based on Richards (1954):

Field performance indicators

It is necessary to justify the effectiveness of newly designed blades and roller cutters, based on some performance indicators. When an applicator operates, the actual rate of the operation within a specified duration can be defined as the effective field capacity (FCeff, ha/h) (Hasan et al., 2018).Working speed (Sw, km/h), theoretical field capacity (FCth, ha/h), FCeff, effevtive and the field efficiency (FE, %) of the blades and the roller cutter were calculated by Hasan et al. (2018) and are as follows:

Where; Sw is the rated forward speed of the machine (km/h), D is the distance of travel (m), T is the time taken to travel (h), w is the rated width of the machine (m), A is the covered area by machine (ha), and t is the time taken to cover the area (h).

Time loss

Time loss was measured during the machine operation by different types of blade in a strip tillage system at different straw heights. Percentage of time loss (TL) was calculated by the equation given below (Haque and Bell, 2017):

The same procedure has been followed to estimate the TL of the machine at different heights of residue in both loose and anchored conditions.

Accumulation of residue in planter during operation

Residue analysis was done for crops collected from fields in the laboratory. At first 20, 30, and 40 cm and full height residue was cut randomly from five places, each of 1 m2 height and then weight of the residue was taken by balance. After that the average weight of each height residue of unit area (1 m2) was calculated. The total weight of residue for each height was calculated by multiplying weight of per square meter area of each height residue by total area. After operation of the planter in 0, 20, 30, and 40 cm heights, accumulated residue in the machine at different heights during operation was collected in the polythene separately and weight of residue of each height was taken. Then the percentage accumulation of residue (Accres) in planter during operation was calculated by dividing total weight of accumulated residue by total weight of residue in the field and multiplying this by 100 (Loomis et al., 2020). This procedure was done separately for each height of residue.

Accres in the machine at different heights of residue was calculated for both loose and anchored conditions in the same procedure.

Results and Discussion

Soil condition

The physical properties i.e. moisture content and ρ of soil was estimated by Equations 2 and 3. At 0 ̶ 7.5 cm soil depth, the averaged initial value of ρ and the averaged moisture content (dry basis) was found to be 0.91 gcm-3 and 30.5%, respectively. On the other hand, the averaged ρ and the averaged moisture content (dry basis) for the soil depth of 7.5 ̶ 15 was found to be 1.04 gcm-3 and 29.7%, respectively (Table 2). However, the averaged moisture content of the soil was found to be in medium state, i.e. not too dry or not too wet. In addition, the physical properties of soil were found almost the same in all places.

Effect of rotary blades in strip tillage system

The field performance of VMP in different straw heights was shown in Figure 8, Tables 3, 4. The FCeff in ST using Blade A in anchored straw condition at different straw heights was found to be 0.099 ha/h, 0.089 ha/h, 0.083 ha/h, and 0.076 ha/h in straw heights of 0 cm, 20 cm, 30 cm, and 40 cm, respectively (Figure 8A, Table 3). Whereas, for Blade B, the corresponding values in anchored straw condition at different straw heights were found to be 0.1 ha/h, 0.09 ha/h, 0.088 ha/h, and 0.082 ha/h, respectively. However, in all the experimental plots, the forward speed of the machine was kept same. FE using Blade A in anchored straw condition at different straw heights was found to be approximately 90%, 80.94%, 75.28%, and 69.2% in straw heights of 0 cm, 20 cm, 30 cm, and 40 cm, respectively (Table 3). On the other hand, FE using Blade B in anchored straw condition at different straw heights was found to be approximately 90.9 %, 84%, 79.68%, 74.52%, which are 1%, 3.7%, 5.84%, 6.76% higher than Blade A, respectively. Effect of straw height on FCeff by using two types of blades in anchored straw was represented in Figure 8A. However, it was observed that FCeff was found to be significantly high using Blade B as compared to that of Blade A. While, FCeff was found to be decreased with the increase in straw height in anchored straw condition by using both Blade A and Blade B (Figure 8A). FCeff in ST by using Blade A in loose straw condition at different straw heights was found to be 0.099 ha/h, 0.07 ha/h, 0.068 ha/h, and 0.063 ha/h, in straw heights of 0 cm, 20 cm, 30 cm, and 40 cm, respectively (Figure 8B and Table 4). Whereas, the FCeff in ST by using Blade B in loose straw condition at different straw heights was found to be 0.1 ha/h, 0.08 ha/h, 0.072 ha/h, and 0.067 ha/h in 0, 20, 30, 40 cm straw heights, respectively. Similar to that of the anchored condition, the forward speed in this loose straw condition was kept the same in all the experimental plots. FE by using Blade A in loose straw condition at different straw heights was found to be 90%, 63.89%, 61.5%, and 57.56%, respectively in 0 cm, 20 cm, 30 cm, and 40 cm straw heights (Table 4). On the other hand, the corresponding variations were found to be 90.9 %, 72.5%, 65.3%, 61.63%, respectively by using Blade B in loose straw condition. The effect of straw heights on the FCeff by using two types of blades in loose straw is shown in Figure 8B. For all four cases, it was evident that FCeff was found to be 1%, 13.4%, 6.1%, and 0.21% higher respectively, by using Blade B rather than using Blade A. However, similar to the anchored condition, a decreasing trend was seen for both blades with an increasing in the straw height in loose straw condition (Figure 8B).

Table 2: Physical properties of soil.

|

Parameters |

Anchored straw |

Loose straw |

||||||

|

Soil depth = 0‒7.5 (cm) |

Soil depth = 7.5‒15 (cm) |

Soil depth = 0‒7.5 (cm) |

Soil depth = 7.5‒15 (cm) |

|||||

|

Mean |

Standard deviation |

Mean |

Standard deviation |

Mean |

Standard deviation |

Mean |

Standard deviation |

|

|

Weight of wet soil (gm) |

284.00 |

11.79 |

332.67 |

15.18 |

290.00 |

13.11 |

357.00 |

10.00 |

|

Weight of sample (gm) |

28.77 |

0.12 |

28.73 |

0.15 |

28.40 |

1.97 |

28.50 |

0.10 |

|

Weight of dry soil (gm) |

217.00 |

8.54 |

255.67 |

11.24 |

223.67 |

11.02 |

275.00 |

7.55 |

|

Moisture content (dry basis, %) |

30.87 |

0.68 |

30.10 |

0.36 |

29.67 |

0.74 |

29.80 |

0.44 |

|

Height of soil sample (cm) |

5.67 |

0.15 |

5.80 |

0.26 |

5.30 |

0.20 |

6.03 |

0.21 |

|

Diameter of soil sample (cm) |

7.30 |

0.10 |

7.33 |

0.06 |

7.43 |

0.06 |

7.30 |

0.00 |

|

Volume (cm3) |

236.67 |

1.15 |

244.67 |

12.74 |

229.67 |

9.29 |

252.00 |

8.89 |

|

Ρ (gm/cm3) |

0.91 |

0.05 |

1.04 |

0.06 |

0.98 |

0.02 |

1.13 |

0.03 |

Table 3: Effect of rotary blades in anchored straw condition.

|

Parameters |

Straw height |

|||||||

|

0 cm |

20 cm |

30 cm |

40 cm |

|||||

|

Blade A |

Blade B |

Blade A |

Blade B |

Blade A |

Blade B |

Blade A |

Blade B |

|

|

Forward speed (km/h) |

1.36 |

1.39 |

1.38 |

1.41 |

1.40 |

1.36 |

1.33 |

1.38 |

|

FCth (ha/h) |

0.11 |

0.11 |

0.11 |

0.11 |

0.11 |

0.11 |

0.11 |

0.11 |

|

FCeff (ha/h) |

0.099 |

0.1 |

0.089 |

0.09 |

0.083 |

0.088 |

0.076 |

0.082 |

|

FE (%) |

90 |

90.9 |

80.94 |

84 |

75.28 |

79.68 |

69.2 |

74.52 |

Table 4: Effect of rotary blades in loose straw condition.

|

Parameters |

Straw height |

|||||||

|

0 cm |

20 cm |

30 cm |

40 cm |

|||||

|

Blade A |

Blade B |

Blade A |

Blade B |

Blade A |

Blade B |

Blade A |

Blade B |

|

|

Forward Speed (km/h) |

1.37 |

1.36 |

1.34 |

1.32 |

1.41 |

1.40 |

1.39 |

1.35 |

|

FCth(ha/h) |

0.11 |

0.11 |

0.110 |

0.11 |

0.11 |

0.11 |

0.11 |

0.11 |

|

FCeff(ha/h) |

0.099 |

0.1 |

0.07 |

0.08 |

0.068 |

0.072 |

0.063 |

0.067 |

|

FE(%) |

90 |

90.9 |

63.89 |

72.5 |

61.5 |

65.3 |

57.56 |

61.3 |

Table 5: Straw accumulations in rotary shaft and furrow opener of machine planter in 17×2.4 m2 area in anchored straw condition.

|

S. No. |

Clogging of residues in |

Straw height |

0 cm |

20 cm |

30 cm |

40 cm |

||||

|

Blade type |

Blade A |

Blade B |

Blade A |

Blade B |

Blade A |

Blade B |

Blade A |

Blade B |

||

|

1 |

Rotary |

Wet wt. (kg) |

0.03 |

0.01 |

0.07 |

0.05 |

0.21 |

0.28 |

0.19 |

0.32 |

|

Dry wt. (kg) |

0.01 |

.004 |

0.03 |

0.02 |

0.08 |

0.1 |

0.07 |

0.12 |

||

|

2 |

Furrow opener |

Wet wt. (kg) |

0.37 |

0.22 |

2.14 |

1.54 |

3.38 |

2.75 |

4.87 |

3.52 |

Table 6: Straw accumulations in rotary shaft and furrow opener of machine planter in 15×2.4 m2 area in loose straw condition.

|

S. No. |

Clogging of residues in |

Straw height |

0 cm |

20 cm |

30 cm |

40 cm |

||||

|

Blade type |

Blade A |

Blade B |

Blade A |

Blade B |

Blade A |

Blade B |

Blade A |

Blade B |

||

|

1 |

Rotary |

Wet wt. (kg) |

0.03 |

0.01 |

0.27 |

0.25 |

0.32 |

0.41 |

0.34 |

0.37 |

|

Dry wt. (kg) |

0.01 |

0.004 |

0.1 |

0.1 |

0.12 |

0.15 |

0.14 |

0.14 |

||

|

2 |

Furrow opener |

Wet wt. (kg) |

0.37 |

0.22 |

3.05 |

2.88 |

5.14 |

4.29 |

6.93 |

3.52 |

|

Dry wt. (kg) |

0.15 |

3.05 |

1.1 |

1.1 |

1.95 |

1.6 |

2.56 |

2.33 |

||

Effect of rotary blades in straw accumulation

Straw accumulation in both anchored straw and loose straw conditions in the field using two types of blade is shown in (Figure 9A and B). Straw accumulation in strip tillage using Blade A was measured to be 9.03%, 10.36%, and 12.14% in 20, 30, and 40 cm straw heights, respectively and using Blade B it was found to be 6.50%, 8.74%, and 8.88% in 20, 30, and 40 cm straw heights, which were 28.01%, 16.63% and 26.85% lower, respectively (Figure 9A). Straw accumulation in loose straw in strip tillage using Blade A was measured to be 15.37%, 17.85%, and 19.05% in 20, 30, and 40 cm straw heights, respectively and by Blade B it was found 14.5%, 15.36%, and 17.47% in 20, 30, and 40 cm straw heights, which were 5.60%, 13.94% and 8.29% lower, respectively (Figure 9B).

In both loose and anchored straw, moisture content was found to be 37.11% (dry basis). The details of the straw accumulation and the weight of the straw (wet basis) in both anchored straw and loose straw conditions in the test field area are illustrated in Tables 5, 6 and 7.

Table 7: Weight of straw at different straw heights (Wet basis).

|

Straw height (cm) |

Anchored straw (kg) in 17×2.4 m2 area |

Loose straw (kg) in 15×2.4 m2 area |

|

20 |

24.48 |

21.6 |

|

30 |

34.68 |

30.6 |

|

40 |

43.25 |

38.16 |

Time loss

TL in both anchored straw and loose straw conditions in the field using two types of blades was measured and represented in Figure 10. TL in ST system by using Blade A was found to be 11.63%, 17.40%, and 25.60%, in 20, 30, 40 cm straw heights, respectively and by Blade B it was found to be 6.98%, 9.77%, and 14.88%, respectively in 20, 30, 40 cm straw heights (Figure 10A). The latter is 39.9%, 43.8%, and 41.87% lower than the TL measured by Blade A for all cases. Whereas, the TL in loose straw in ST system at different straw heights by using Blade A was measured 26.67%, 33.95%, and 39.70%, respectively in 20, 30, 40 cm straw heights. TL in ST systems at different straw heights by using Blade B was measured 16.28%, 25.74%, and 30.47%, respectively in 20, 30, 40 cm straw heights (Figure 10B). However, the time by using Blade B was found to be less (in all the cases) than compared with that of the Blade A in both the anchored and loose straw conditions.

Fuel consumption

Fuel consumption in different tillage methods is shown in (Figure 11). In the ZT system the fuel consumption was approximately 12.15 L/ha, and in the ST system the fuel consumption was found to be approximately 10.52 L/ha. Thus, the fuel consumption in the ZT system was found to be more (15.49%) compared to that of the ST system because the roller cutter was a much heavier device (48 Kg) than rotary blades which required more energy to rotate the roller cutter.

Performance tests

Performance of blades in strip tillage system: Strip made by planters using Blade A and Blade B was measured by its depth and width. The strip depth and strip width of cut for both the Blade A and the Blade B was found to be the same (Table 8). A photographic comparison of strips made by Blade A and Blade B is shown in Figure 12. In the ST system, the soil covering was visually seen well with the Blade B.

Table 8: Depth and width of cut of strip using two types of blades.

|

Blade type |

Depth (cm) |

Width (cm) |

||

|

Blade A |

7.5 |

2.5 |

||

|

Blade B |

7.5 |

2.5 |

||

Performance of roller cutter in zero tillage system

In the ZT system the strip created by the roller cutter was measured by its depth and width accordingly. While using the roller cutter, the strip depth and the strip width was found to be 1 cm, and 2.5 cm, respectively (Table 9). In the ZT system, it was noticed that the power tiller cannot rotate the roller smoothly when the roller comes in contact with soil because of high frictional force. In addition, because of the pushing residues in the strip by cutters, residues behaved as loose straw in the field which accumulates more residues in the furrow opener. Thus, further research is needed to resolve these issues while operating the roller cutter in the ZT system.

Table 9: Depth and width of cut of strip using furrow opener and the cutter.

|

Strip dimension |

Strip created by furrow opener (cm) |

Strip created by roller cutter without furrow opener (cm) |

|

Width |

2.5 |

1 |

|

Depth |

7.5 |

2.5 |

Conclusions and Recommendations

The effects of difference of rotary blades and roller cutter, on residue management were investigated against different straw heights. The VMP operated by power tiller was used as a prime mover in the field tests with an objective of residue management. The FCeff in strip tillage with Blade B was observed higher for all the lengths of straw as compared to that of Blade A in both anchored and loose straw positions. The straw accumulation in ST with Blade B was found to be less, 28.01%, 16.63% and 26.85% for straw height 20, 30, 40 cm, respectively in comparison to that of Blade A for both positions. TL was found to be higher with Blade A due to additional accumulation of straw on the furrow opener. Furthermore, with the increase in straw lengths, field capacity was decreased but straw accumulation and TL were increased for both types of blades positions. Therefore, Blade B was found to be more effective compared to that of Blade A. Moreover, in the ZT system, roller cutters pushed residues into strips and behaved like loose in-furrow opener, which accumulated additional straws in-furrow opener. VMP with Blade B is more suitable in anchored straw condition than loose straw condition in the field in both ST and ZT practices. Hence, roller cutters are not a better option in the ZT system due to overweight and additional straw in the furrow opener. Additional devices could be designed to improve residue management.

Novelty Statement

This research paper aims to assess the effect of rotary blades and roller cutters of VMC on residue management in farm fields of Bangladesh. Design improvement approach has been applied to improve the blade of the roller cutter and rotary blades. Experimental results have shown good agreement with decreased straw accumulation. Verification tests have also been performed at different straw heights in the field. However current study used various design improvement approaches which are rare in the literature to find the effect of improved design on the residue management.

Author’s Contribution

Abdullah Al-Musabbir: Conceptualization, investigation, formal analysis, visualization, writing original draft.

Md Abedur Rahman: Literature review, formal analysis, visualization, writing original draft, writing review, and editing.

Naveed Anjum: Proofreading.

Mustajab Ali: Literature review, proofreading, writing review, and editing.

Conflict of interest

The authors have declared no conflict of interest.

References

Ali, M., 2021. A global assessment of solar photovoltaic resource and energy-water nexus for future sustainability. PhD thesis, The University of Tokyo, Japan. Available at: http://hydro.iis.u-tokyo.ac.jp/Mulabo/thesis.html.

Ali, M., and H. Kim. 2021. Global assessment for reduction of solar photovoltaic potential due to meteorological and geomorphological limiting factors. EGU General Assembly 2021, April 19–30, 2021, Online, pp. EGU21-5773. https://doi.org/10.5194/egusphere-egu21-5773

Badarinath, K.V.S., T.R.K. Chand and V.K. Prasad. 2006. Agricultural crop residue burning in the Indo-Gangetic plains. A study using IRS-P6 AWiFS satellite data. Curr. Sci., 91(8): 1085-1089.

Banerjee, S., and R.M. Punekar. 2020. A sustainability-oriented design approach for agricultural machinery and its associated service ecosystem development. J. Cleaner Prod., 264: 121642. https://doi.org/10.1016/j.jclepro.2020.121642

Baudron, F., B. Sims, S. Justice, D.G. Kahan, R. Rose, S. Mkomwa, P. Kaumbutho, J. Sariah and R. Nazare. 2015. Re-examining appropriate mechanization in Eastern and Southern Africa: two-wheel tractors, conservation agriculture, and private sector involvement. Food Secur., 7(4): 889-904. https://doi.org/10.1007/s12571-015-0476-3

Bird, J.A., W.R. Horwath, A.J. Eagle and C.V. Kessel. 2001. Immobilization of fertilizer Nitrogen in rice: effects of straw management practices. Soil Sci. Soc. Am. J., 65: 1143-1152B. https://doi.org/10.2136/sssaj2001.6541143x

Celik, A., and S. Altikat. 2010. Effects of various strip widths and tractor forward speeds in strip tillage on soil physical properties and yield of silage corn. J. Agric. Sci., 16(3): 169-179. https://doi.org/10.1501/Tarimbil_0000001136

Chabert, A., and J.P. Sarthou. 2020. Conservation agriculture as a promising trade-off between conventional and organic agriculture in bundling ecosystem services. Agric. Ecosyst. Environ., 292: 106815. https://doi.org/10.1016/j.agee.2019.106815

Gregg, E.S., J. Colton, M.A. Matin and T.J. Krupnik. 2020. Efficient and participatory design of scale-appropriate agricultural machinery workshops in developing countries: A case study in Bangladesh. Dev. Eng., 5(2): 100046. https://doi.org/10.1016/j.deveng.2019.100046

Gregorio, G.B., and R.C. Ancog. 2020. Impact of COVID-19 pandemic on agriculture production in Southeast Asia: Reinforcing transformative change in agricultural food systems. SEAMEO-SEARCA, Policy Paper, 1. https://doi.org/10.37801/ajad2020.17.1.1

Gupta, S.C., and W.E. Larson. 1979. Estimating soil water retention characteristics from particle size distribution, organic matter percent, and bulk density. Water Resour. Res., 15(6): 1633–1635. https://doi.org/10.1029/WR015i006p01633

Haque, M.E., and R.W. Bell. 2017. Performance of the versatile multi-crop planter (2010-2017). In 2nd Conference on Conservation Agriculture for Smallholders, 14-16 February 14-15, 2017; Mymensingh, Bangladesh, pp. 58-60.

Haque, M.E., R.W. Bell, A.K.M.S. Islam, K. Sayre and M.M. Hossain. 2011. Versatile multi-crop planter for two-wheel tractors: an innovative option for smallholders. In: World Congress on Conservation Agriculture, September 26-29, 2011; Brisbane, Australia, pp. 78-90.

Hasan, M.M., M.A. Rahman and M.A. Rabbani. 2018. Design and development of manually push type urea super granule applicator. Agric. Eng. Int. CIGR J., 20(2): 80–87.

Hossain, M.I., M. Sarker and M.A. Haque. 2015. Status of conservation agriculture based tillage technology for crop production in Bangladesh. Bangladesh J. Agric. Res., 40(2): 235–248. https://doi.org/10.3329/bjar.v40i2.24561

Huang, X., W. Yang, W. Wang, Z. Li and L. Chen. 2018. Design and experiment of straw shifting anti-blocking maize seed drill. Int. Agric. Eng. J., 27(3): 20.

Islam, A.K.M.S., M.E. Haque, M.M. Hossain, M.A. Saleque and R.W. Bell. 2010. Water and fuel saving technologies: Un-puddled bed and strip tillage for wet season rice cultivation in Bangladesh. In: Proceedings of the 19th World Congress of Soil Science; Soil Solutions for a Changing World, August 1-6, 2010, Brisbane, Australia, pp. 169-172.

Jahun, B.G., M. Yamin, D.B. Ahmad, M.R. Mahdi, S. Suleiman and S.A. Abdulkadir. 2020. Parametric analysis of the mulching depth of oil palm fronds achieved by tractor operated mulcher. Sarhad J. Agric., 36(2): 632-638. https://doi.org/10.17582/journal.sja/2020/36.2.632.638

Loomis, G., B. Dari, C.W. Rogers and D. Sihi. 2020. Evaluation of residue management practices on barley residue decomposition. PLoS One, 15(5): e0232896. https://doi.org/10.1371/journal.pone.0232896

Loon, J.V., L. Woltering, T.J. Krupnik, F. Baudron, M. Boa and B. Govaerts. 2020. Scaling agricultural mechanization services in smallholder farming systems: Case studies from sub-Saharan Africa, South Asia, and Latin America. Agric. Syst., 180: 102792. https://doi.org/10.1016/j.agsy.2020.102792

Martín-Lammerding, D., J.L. Gabriel, E. Zambrana, I. Santín-Montanyá and J.L. Tenorio. 2021. Organic amendment vs. mineral fertilization under minimum tillage: Changes in soil nutrients, soil organic matter, biological properties and yield after 10 years. Agriculture, 11(8): 700. https://doi.org/10.3390/agriculture11080700

Molotoks, A., P. Smith and T.P. Dawson. 2020. Impacts of land use, population, and climate change on global food security. Food Energy Secur., 10(1): e261. https://doi.org/10.1002/fes3.261

Mondal, K.G., A.K. Misra, K.M. Hati, K.K. Bandyopadhyay, P.K. Ghosh and M. Mohanty. 2004. Rice residue management options and effects on soil properties and crop productivity. J. Food Agric. Environ., 2(1): 224-231.

Rahman, M.A., M. Ali, M.A. Mojid, N. Anjum, M.D. Haq, A. Kainose and K.D.C.R. Dissanayaka. 2022. Crop coefficient, reference crop evapotranspiration and water demand of dry season boro rice as affected by climate variability: A case study at the north–east Bangladesh. Irrig. Drain. (Accepted article-in press).

Rahman, M.A., M.E. Haq and N. Anjum. 2019. Potential crop water requirements of dry season Boro rice under climate change in North-East hydrological region of Bangladesh. Agric. Eng. Int. CIGR J., 21(4): 1–13.

Rahman, M.A., and M.M. Hasan. 2016. Performance evaluation of Buraghat rubber dam project in irrigation development at Haluaghat in Mymensingh. Tech. J. River Res. Inst., 13(1): 26-36.

Rahman, M.A., N.N. Karim, M.N., Kadir and T. Naher. 2015. Impacts of climate change on crop coefficient and reference crop evapotranspiration of Boro rice in north-east hydrological region of Bangladesh. In: Proceedings of Fifth International Conference on Water and Flood Management, March 03-05, 2015., Dhaka, Bangladesh, pp. 209-216.

Richards, L.A., 1954. Diagnosis and improvement of saline and alkali soils. USDA Agric. Handbook 60, U.S. Govt. Printing Office, Washington, D.C., USA.

Sakai, J., 1977. Some design know-hows of edge-curve angle of rotary blades for paddy rice cultivation. Agric. Mech. Asia, Africa and Latin Am., 8(2): 49–57.

Sanaullah, A. Basit, and I. Ullah. 2021. Challenges and prospects of farm mechanization in Pakistan: A case study of rural farmers in District Peshawar Khyber Pakhtunkhwa. Sarhad J. Agric., 37(1): 167-179. https://doi.org/10.17582/journal.sja/2021/37.1.167.179

Sidhu, B.S. and V. Beri. 2008. Rice residue management: Farmer’s perspective. Indian J. Air Pollut. Cont., 8(1): 61-67.

Steel, R.G.D and J.H. Tome. 1980. Principals and procedures of the statistics: A biological approach. 2nd Ed. McGraw Hill Book Co. New York.

Tabriz, S.S., M.A. Kader, M. Rokonuzzaman, M.S. Hossen and M.A. Awal. 2021. Prospects and challenges of conservation agriculture in Bangladesh for sustainable sugarcane cultivation. Environ. Dev. Sustain., 23(11): 15667-15694. https://doi.org/10.1007/s10668-021-01330-2

Tang, H., J. Yang, F. Wang, X. Li and J. Li. 2018. Measurement and analysis of rolling friction coefficient of maize seed based on high-speed photography. Int. Agric. Eng. J., 27(3): 22.

Valin, H., P. Havlík, A. Mosnier, M. Herrero, E. Schmid and M. Obersteiner. 2013. Agricultural productivity and greenhouse gas emissions: Trade-offs or synergies between mitigation and food security? Environ. Res. Lett., 8(3): 035019. https://doi.org/10.1088/1748-9326/8/3/035019

To share on other social networks, click on any share button. What are these?