Quality and Consumer Acceptability of Cottage Cheese Prepared from the Blend of Cow and Goat Milk

Research Article

Quality and Consumer Acceptability of Cottage Cheese Prepared from the Blend of Cow and Goat Milk

Aamara Ibrahim1, Ihsan Mabood Qazi1, Majid S. Hashmi1, Ayaz Ahmad1*, Hisham Javed1, Fawad Ahmad2 and Sadia Mukhtar1

1Department of Food Science and Technology, The University of Agriculture, Peshawar, Khyber Pakhtunkhwa, Pakistan; 2Department of Food Science and Technology, Abdul Wali Khan University, Mardan, Khyber Pakhtunkhwa, Pakistan.

Abstract | This research delves into studying how mixing cow and goat milk affects the physical, chemical, microbiological and taste aspects of cottage cheese. Different concentrations (%) of cow and goat milk were mixed such as (CG1 (100:0) served as control, CG2 (90:10), CG3 (80:20), CG4 (70:30), CG5 (60:40), CG6 (50:50) and CG7 (0:100)) to prepare milk blends. The analysis of physical and chemical properties showed notable differences in composition among the milk blends, with goat milk has higher fat content (4±0.003%) while cow milk has more lactose (4.6±0.1%). The pasteurized milk was gently heated followed by addition of addition of acid coagulant. After setting whey was separated and the cottage cheese was stored at 5±1oC. The time for coagulation and cheese yield varied based on the blend composition, with goat milk speeding up coagulation (19.69±1.2 sec) but reducing cheese yield (20.75±1.6%). During storage, the protein and fat content of cottage cheese varied significantly across blends; higher goat milk content resulted in lower protein (15.13±0.3%) and higher fat levels (23.6±0.3%). Microbial analysis indicated that goat milk and blends with higher concentrations of it exhibited more microbial growth compared to cow milk (7.46±0.01 log CFU g-1 and 7.14±0.06 log CFU g-1 respectively). However, blends with up to 30% goat milk had minimal impact on microbial growth. Sensory evaluation highlighted that blends containing 20-30% goat milk were most favored by judges as they were similar to cow milk cheeses in terms of color, aroma, flavor and texture (8.97, 8.89, 8.44, and 7.48 respectively). Mixing 20-30% goat milk with 70-80% cow milk results in a cottage cheese blend that is balanced in terms of nutrition and aligns with consumer preferences. However, it is important to note that the applicability of these findings may vary based on regional sensory preferences, highlighting the need for additional research involving diverse populations. This research offers valuable information for dairy companies looking to expand their range of cheeses prepared from different species like cow and goat while ensuring both quality and consumer satisfaction.

Received | June 17, 2024; Accepted | August 29, 2024; Published | October 28, 2024

*Correspondence | Ayaz Ahmad, Department of Food Science and Technology, The University of Agriculture, Peshawar, Khyber Pakhtunkhwa, Pakistan; Email: [email protected]

Citation | Ibrahim, A., I.M. Qazi, M.S. Hashmi, A. Ahmad, H. Javed, F. Ahmad and S. Mukhtar 2024. Quality and consumer acceptability of cottage cheese prepared from the blend of cow and goat milk. Sarhad Journal of Agriculture, 40(4): 1330-1343.

DOI | https://dx.doi.org/10.17582/journal.sja/2024/40.4.1330.1343

Keywords | Cow milk, Goat milk, Cottage cheese, Microbial quality, Organoleptic characteristics

Copyright: 2024 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

Cottage cheese is a versatile and nutrient-dense dairy product that holds great importance in our diet. Not only has a rich source of protein, but it also provided essential vitamins and minerals necessary for maintaining a healthy body (Abdul-Hakim et al, 2023). Generally, cottage cheese comprises moisture, fat, protein, lactose and minerals (55-70%, 22-27%, 17-18%, 2.0-2.5%, 1.5- 2.0%, respectively). Furthermore, cottage cheese contains biologically active amino acids, peptides, and lactic acid bacteria that have probiotic benefits. These probiotic bacteria promote gut health, aid in digestion, and boost the immune system (Linares et al., 2017; Ho et al., 2016). Additionally, cottage cheese has a unique texture and flavor that contributes to the overall quality of this dairy food. Therefore, incorporating cottage cheese into our diet can provide numerous health benefits and contribute to a well-balanced and nutritious eating plan (Linares et al., 2017).

In 2020, the global production of cottage cheese reached approximately 2.89 million metric tons, with the United States being the largest producer. The revenue generated annually from cottage cheese sales worldwide amounted to around $4.5 billion (Setyawardani et al., 2023). In Pakistan, cottage cheese production has been steadily increasing, reaching an estimated 150,000 metric tons in 2020. The annual revenue generated from cottage cheese sales in Pakistan is approximately $120 million. These statistics highlight the significant role of cottage cheese in both the global and Pakistani dairy industries, showcasing its popularity and economic significance in the market (Hayat and Meena, 2023).

Cow milk is mostly utilized for the production of cottage cheese due to its suitable chemical composition yielding cheese of soft uniform consistency (Chakraborty et al., 2021). Cow milk is low in fat, high in protein and lactose (Rasheed et al., 2016; Boikhutso, 2010). The chemical composition of goat milk which is rarely used in cheese production refers to the specific makeup and concentration of various substances present in the milk (Noël et al., 2008). These substances include proteins, fats, carbohydrates, vitamins, minerals, and other compounds. Goat milk typically contains a higher proportion of certain compounds compared to cow milk, such as smaller fat globules (Clark and Gracia, 2017), a higher concentration of short- and medium-chain fatty acids, and higher levels of vitamins A and D. It also has a higher concentration of certain minerals like calcium, phosphorus, potassium, and magnesium compared to cow milk (Dunshea et al., 2019).

Mixing cow and goat milk for cottage cheese production offers numerous benefits that enhance the taste, texture, and nutritional value of the final product (Prazeres et al., 2012). However, among milk from different species, cow milk is mostly used for consumption and dairy product manufacturing (Kodrik et al., 2011). Cow milk has a mild, creamy taste, while goat milk has a slightly tangy and more robust flavor (Sharmila et al., 2018; Moatsou and Park, 2017). By mixing these two milks, the resulting cottage cheese will have a balanced and complex taste that appeals to a wide range of palates (Gallardo-Escamilla et al., 2005). Additionally, mixing cow and goat milk for cottage cheese production can improve the texture of the cheese. Goat milk has smaller fat globules compared to cow milk, which can result in a smoother and creamier texture (Clark and Gracia, 2017; Prazeres et al., 2012).

Physicochemical properties play a crucial role in determining the sensory characteristics of cottage cheese (Gallardo-Escamilla et al., 2005). For example, the moisture content of cottage cheese can affect its texture, with higher moisture levels resulting in a softer and creamier texture (Kindstedt, 2014). Additionally, the pH level of cottage cheese can impact its flavor, as a higher pH can lead to a more acidic and tangy taste. Furthermore, the presence of specific chemical compounds in cottage cheese, such as volatile organic compounds, can contribute to its aroma (Štefániková et al., 2020). These physicochemical properties interact with each other and with the various components of cottage cheese, such as proteins, lipids, and carbohydrates, to create the overall sensory experience of cottage cheese. Moreover, microbial analyses play a vital role in cottage cheese production, as they help ensure product safety, extend shelf life, and maintain desirable sensory characteristics (Ali et al., 2022).

Keeping in view the need to combine cow and goat milk, current study is conducted (1) to identify a formulation of cow and goat milk blends for producing cottage cheese that meets the acceptance standards of consumers who are accustomed to cottage cheese made solely from cow milk. (2) to determine different concentration of cow and goat milk on coagulation time and yield percentage of cottage cheese, (3) to measure physicochemical properties and microbial growth during shelf-life of cottage cheese, and (4) to evaluate sensory characteristics and consumer acceptance of cottage cheese produced from different concentration of cow and goat milk.

Materials and Methods

Milk collection and cheese preparation

Whole cow and goat milk were obtained from the dairy farm of the University of Agriculture, Peshawar and brought to the laboratory of Food Science and Technology and the milk was then pasteurized at 85±1oC for 19±1 sec. The pasteurized milk was cooled to 32oC and different concentrations of cow and goat milk were combined to obtain the following concentration: CG1 (100:0) served as control, CG2 (90:10), CG3 (80:20), CG4 (70:30), CG5 (60:40), CG6 (50:50) and CG7 (0:100). After preparing different concentrations of cow and goat milk, samples were taken to determine composition of the milk using Lactoscan (Milkotronic, Bulgaria) followed by addition of 2% starter culture of mesophilic bacteria (Raleigh, North Carolina, USA). Acid coagulant (vinegar) was added with constant and gentle stirring. After coagulation, the curd was allowed to settle for 5 min and whey was removed using clean muslin cloth. The curd was pressed (0.025 MPa) for 20 min at 23±1oC to obtained cottage cheese. The cheese so obtained was divided into cubes of 5.8 X 5.8 X 2 cm and stored in polythene bags at 5±1oC for 15 days. The samples were analyzed for physicochemical, microbiological and organoleptic characteristics at 0, 5,10, and 15 days intervals.

Physicochemical analyses

Coagulation time: Coagulation time is defined as the interval between addition of coagulant and appearance of curd and is measured in second (Derra et al., 2018).

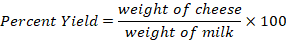

Percent yield: To calculate percent yield of the cottage cheese, the following formula was used as specified by Darwish et al. (2024).

Chemical analyses

The chemical composition of cottage cheese (protein, fat, ash, moisture, and acidity) was determined based on the standardized procedures of the AOAC (2005). To determine pH value of the homogenized cottage cheese samples, a digital pH meter (HANS-12, Hanna Instruments, USA) was used (Barukčić et al., 2020).

Microbiological analyses

Microbiological quality of cottage cheese during the storage period of 15 days at 5±1oC was determined in terms of (a) viable cell counts of aerobic bacteria (ISO, 2013), (b) Enterobacteriaceae (ISO, 2004) and (c) yeast and molds (ISO, 2008).

Sensory analyses

Sensory analyses of the cottage cheese were carried out in terms of color, aroma, taste, texture, and overall acceptability. The analyses were done by 30 panelists (15 females and 15 males) from the faculty of nutrition sciences, the University of Agriculture, Peshawar, who already consume cottage cheese as part of their diet. Moreover, all the panelists were trained on organoleptic characteristics of cottage cheese made from cow milk available in the local market. The age of the judges ranged from 25 to 50 years. The samples of cottage cheese (20 g) were placed in coded disposable plastic cups and served to the panelist at room temperature along with water to rinse mouth during the analyses. The judges gave score according to 9-point hedonic scale where 9 is very like and 1 is very dislike (Darwish et al., 2024).

Statistical analyses

The collected data was analyzed through one-way ANOVA using Statistix 10 (Analytical Software 2105 Miller Landing Rd Tallahassee, USA) statistical software. The means were compared using LSD at a significance level of P≤0.05. All the experiments were performed three times and the results were expressed as mean ± SD.

Results and Discussion

Composition of blended milk

After blending cow and goat milk in various concentrations, composition of the blended milk was determined in regard of TSS, acidity, fat, lactose, moisture, protein and ash content as shown in Table 1. All of the concentrations exhibited a significant difference (P≤0.05) in TSS content, with the highest TSS observed in CG1 (13±0.7%) and the lowest in CG7 (12.03±0.4%). The first four blends from CG1 to CG4 and the last three blends from CG5 to CG7 exhibited a nonsignificant variation in acidity and protein content. Nevertheless, there was a significant variation in acidity and protein content between the mentioned groups. Likewise, no significant variation was observed in the fat content of the first six blends from CG1 to CG6, but CG7 exhibited higher fat content (4±0.03%), significantly higher than the mentioned six milk blends. As opposed to acidity and fat content, a significant variation was noticed in the lactose content of all the seven blends, with the highest lactose content observed in CG7 (4.35±0.03%) and the lowest in CG1 (4±0.1%). Both the moisture and ash content of CG7 were significantly higher than the first five blends from CG1 to CG5, however, there was no significant variation observed between CG7 and CG6.

The significant variation in TSS amongst different milk blends (CG1 to CG7) elucidates the effect of milk composition on this key variable. The maximum TSS content in CG1 and minimum in CG7 specifies that the amount of cow and goat milk in the blend plays an indispensable role in controlling the overall solubility of solids due to difference in moisture content (Boikhutso, 2010). Cow milk has a higher TSS content as compared to goat milk owing to differences in protein and lactose concentrations (Collard and McCormick, 2021). Consequently, a blend with a greater proportion of cow milk, such as CG1, will naturally show high level of TSS (Turkmen, 2017). These results are aligned with existing literature on the composition of milk and TSS content, which indicate that rise in moisture content leads to lowered TSS in the milk (Collard and McCormick, 2021; Clark and García, 2017). The nonsignificant variation in acidity and protein content among CG1 to CG4 and CG5 to CG7 propose a negligible difference exist in acidity and protein content of cow and goat milk which is also apparent from previous studies of (Chen et al., 2022; Roy et al., 2020; Mahmood and Sumaira, 2010). While CG1 to CG6 maintain relatively constant fat levels, CG7 shows a remarkable deviation, suggesting a possible tipping point in fat composition (Clark and García, 2017). Factors such as lipid compatibility, triglyceride composition, and fatty acid profiles, species, breed, animal diet, geographical area, and milking time may affect the observed variation in fat content across different milks (Akshit et al., 2024; dos Santos et al., 2023; Filipczak-Fiutak et al., 2021; Boikhutso, 2010). In addition, some studies have proposed an inverse relation between fat and protein content where increase in the fat content leads to decrease in the protein content of the milk (Van Boekel, 1994). The significant differences in lactose content across all seven blends indicate the visible carbohydrate composition of cow and goat milk and their effects in blended formulations (Álvarez-Rosales et al., 2019). Lactose, which is the primary carbohydrate in milk, directly affects nutritional characteristics, sweetness, TSS and solubility (Hettinga, 2019). The higher TSS content in CG1 compared to CG7 shows higher lactose in cow milk, which is consistent with previous results (Collard and McCormick, 2021; Clark and García, 2017). Lactose is not given much importance during cheese manufacturing as it is generally degraded to lactic acid, however, in cottage cheese some amount of lactose remained as these are often referred to as fresh (Boikhutso, 2010). Significant variations in moisture and ash content between CG7 and CG1 to CG5 indicate differences in water and mineral content resulting from different blend compositions. The lower TSS and lactose content in goat milk followed (Table 1) by lower protein clearly indicate highest moisture and ash content in CG7 (Roy et al., 2020). These results are aligned with previous studies conducted on cow and goat milk composition (Álvarez-Rosales et al., 2019; Clark and García, 2017). These differences may affect product nutritional value, texture, and flavor (Guetouache et al., 2014), necessitating careful consideration during product development and quality control processes.

Coagulation time and cheese yield

The coagulation time and percent yield of cottage cheese made from blend of cow and goat milk in different concentration varies depending on the amount of milk used (Table 2). It is clear from the results that the coagulation time for cow milk (29.28±1.4 sec) is significantly higher as compared to other blended milk and goat milk (19.69±1.2 sec). As the amount of goat milk is increased, the coagulation time tends to decrease. Additionally, cheese made from cow and goat milk in different concentrations showed higher coagulation time compared to goat milk alone. Likewise, the percent cheese yield for cow milk (27.10±1.9%) is also higher than that for cheese made from goat milk (20.75±1.6%). The percent cheese yield tends to reduce with increasing concentration of goat milk from CG2 to CG6, as shown in Table 2.

The findings of this study on the coagulation time and percentage yield of cottage cheese made from various blends of cow and goat milk provide important insight into the effect of milk concentration on cheesemaking parameters. The increase in coagulation time of cow milk compared to goat milk shows that there are inherent differences in the composition or characteristics of the two types of milk from two different species, (Table 1) that affect the coagulation process (Vacca et al., 2020; Puledda et al., 2017; Sadia et al., 2015). The longer coagulation time of cow milk can be ascribed to factors such as higher concentrations of certain proteins, casein micelle structure (Clark and Sherbon, 2000), differences in the size and composition of fat globules (Troch et al., 2017; Fekadu et al., 2005). As the concentration of goat milk is increased in the blend, the coagulation time tends to reduce. This trend shows that goat milk with higher fat content facilitates faster coagulation than cow milk (Clark and Sherbon, 2000). It can be inferred that the presence of certain enzymes or proteins in goat milk enhances the coagulation process, leading to faster formation of curd (Stocco et al., 2018). Cheese made from blended milk shows higher coagulation time compared to goat milk alone indicates that the addition of cow milk may introduce factors that interfere with or slow down the coagulation process such as decrease in calcium ion and increase in size of casein micelle (Park et al., 2007; George and Ace, 1984). This could be due to the dilution of certain coagulation-promoting components present in goat milk or the presence of inhibitory substances in cow milk (Park, 1994). Similarly, the higher percentage yield of cheese from cow milk than goat milk indicates the difference in the cheese-making potential of these two types of milk (Vacca et al., 2020). Cow milk contains a higher proportion of large fat globules that contribute to curd formation and retention, leading to a higher cheese yield per unit volume of milk (Fekadu et al., 2005). The decrease in percent cheese yield with increasing amount of goat milk in the mixture further proposes that goat milk may not be as effective in producing cheese as compared to cow milk. This is attributed lower total solids and protein content of goat milk, which may result in reduced curd formation or reduced curd retention during cheesemaking (Sadia et al., 2015).

Composition of cottage cheese

The protein content of cow and goat milk blend cottage cheese varies significantly depending on the amount of each milk type. Throughout the storage period of 15 days, cheese made from cow milk showed a higher protein content compared to goat milk (Figure 1A). Moreover, with an increase in the concentration of goat milk, the protein content tends to decrease; however, the variation remained statistically no significant for CG1, CG2, CG3, CG4, and CG5. Increasing the concentration of goat milk above 40% significantly reduces protein content. This trend was noticed in all intervals during the storage period. Likewise, the fat content of the cottage cheese also varied during the 15-day storage duration (Figure 1B). Cottage cheese with higher concentration of goat milk tended to have lower fat content as compared to higher concentration of cow milk. Initially, CG1 and CG2 showed significantly higher fat content and maintained this trend throughout the storage duration. In contrast to protein and fat content, ash content reduced with an increasing concentration of cow milk (Figure 1C). Goat milk alone showed significantly higher ash content compared to cow milk and other blends. Nonetheless, blending cow and goat milk exhibited a slight impact on ash content during the storage duration. Likewise, moisture content also showed a decreasing trend with an increase in the concentration of cow milk (Figure 1D). Cow milk alone showed significantly lower moisture content compared to goat milk. Titratable acidity and pH of the cottage cheese samples during the storage period of 15 days is represented in Figure 2A, B. On day 1, lowest TA and highest pH values were observed for CG1 followed by CG2 and consecutive samples, while highest TA and lowest pH values were observed in CG7. Throughout storage period this trend continues in all samples till day 15.

The results of this study elucidate the compositional changes in cheese using different proportions of cow and goat milk mixtures during a 15-day storage period. This study observed changes in protein, fat, ash, and moisture content, providing useful insight into the effects of milk type concentration on the quality and nutritional properties of cottage cheese (Figure 1). One of the key findings was the notable effect of milk type concentration on the protein content of cottage cheese (Abd El-Gawad and Ahmed, 2011). Cheese made from cow milk consistently presents higher protein content than goat milk. This finding is consistentwith previous research showing that cow milk generally has a higher protein content

than goat milk (Ali et al., 2021; Sadia et al., 2015). However, as the concentration of goat milk increased, there was a tendency for protein content to decrease (Sadia et al., 2015), although this decrease was not statistically significant for some proportions of cow and goat milk blends (Table 1). In particular, a significant decrease in protein content was observed when goat milk content exceeded 40%. This decrease in protein content can be attributed to many of factors, including differences in the protein composition of cow and goat milk (Mahmood and Sumaira, 2010), as well as possible interactions between proteins during cheese formation and storage (Guinee, 2016). Similarly, the fat content of cottage cheese varies depending on the concentration of cow and goat milk blends (Clark and García, 2017). Cheese made with a higher concentration of goat milk have lower fat content than those with a higher concentration of cow milk (Sadia et al., 2015). Intriguingly, cottage cheese samples with low concentration of goat milk such as CG1 and CG2, initially showed significantly higher fat content and maintained this trend throughout the storage duration (Figure 1). This shows that the composition of the milk blend can affect the fat content of cottage cheese (Bland et al., 2015), which may have potential effects on organoleptic characteristics as well (Martin et al., 2016). This research also examined the ash content of cottage cheese, which represents the mineral content of milk (Manuelian et al., 2017). Goat milk alone has significantly higher ash content than cow milk, possibly due to differences in mineral composition between the two types of milk (Clark and García, 2017; Sadia et al., 2015). However, mixing of cow and goat milk showed minimal effect on ash content during the storage period. Nevertheless, it is noteworthy that the ash content decreased with increasing concentration of cow milk, indicating a weak effect on the mineral content of cheese (Boukria et al., 2020). The moisture content of cottage cheese showed a decreasing trend with increasing concentration of cow milk (Akshit et al., 2024). Cow milk alone has a significantly lower moisture content than goat milk, which is aligned with the higher total solids and protein content found in cow milk (Collard and McCormick, 2021; Roy et al., 2020; Álvarez-Rosales et al., 2019). This elucidates the importance of milk type selection in determining the moisture and overall texture of cottage cheese. Higher pH and lower acidity are prerequisite for paste stability, which can be made possible using thermophilic starter culture (Batty et al., 2019). In this study a significant difference was observed in pH and acidity based on the concentration of cow and goat milk in the blends. Earlier, Sadia et al. (2015) has reported higher pH and consequently lower acidity in cottage cheese made from cow milk. pH is generally believed to be the most important indicator of cheese quality during production and storage (Johnson, 2017; Razzaq, 2003). Previously, pH of cottage cheese has been reported in the range of 3.7-4.6, however, in our case maximum pH observed in cheese sample made from cow milk was 4.86 which reduced to 4.82 after 15 days of storage. This might be due to the type of coagulant used in cheese making (Yasar and Guzeler, 2011). Moreover, difference in ash content and acidity of milk also affect pH and TA of cheese (Sadia et al., 2015) reported that pH and acidity of the cheese is affected by the type of coagulant used and the source of milk (Birhanu et al., 2013). In addition to affecting coagulation, pH also affects organoleptic characteristics and microbial population of cottage cheese (Possas et al., 2021; Sadia et al., 2015). TA is considered as better predictor of taste and aroma than pH and varies depending on the type of cheese (Tyl and Sadler, 2017).

Microbial quality

As illustrated in Figure 3A, the total viable cell count ranged from 5.43 to 5.51 log CFU g-1. Cheese made from cow milk and milk with a higher concentration of cow milk exhibited a lower total viable count; however, the differences were not statistically significant. From day 5 onwards, CG7 and CG6 showed significantly higher total viable counts, at 6.86 and 6.82 log CFU g-1, respectively. On the last day of storage, the lowest viable count was observed in CG1, CG2, and CG3, at 7.14, 7.16, and 7.164 log CFU g-1 respectively. A similar trend was also observed for Enterobacteriaceae and yeasts and molds, as depicted in Figure 3B, C. Cheese made from cow milk and a higher concentration of cow milk showed lower levels of Enterobacteriaceae and yeasts and molds. Initially, on day 0, no Enterobacteriaceae and yeasts and molds were detected in any of the samples. However, from day 5 onwards, the growth of Enterobacteriaceae and yeasts and molds began, reaching 2.29 and 2.54 log CFU g-1 in CG1, significantly lower than the other six samples. CG2, CG3, and CG4 showed statistically similar results, significantly higher than CG5, CG6, and CG7 for Enterobacteriaceae. In contrast to Enterobacteriaceae, CG1, CG2, and CG3 showed similar results for yeasts and molds, lower than the other remaining samples. Overall, cheese made from goat milk and blends containing a higher concentration of goat milk showed more microbial growth compared to cow milk. However, mixing goat milk in concentrations up to 30% has little to no impact on microbial growth.

The results presented in the microbial quality analysis of cottage cheese samples provide valuable insight into the impacts of milk type and concentration on microbial growth during storage. The total viable cell count is an important indicator of the microbial load in cheese and reflects the overall microbial population present (Barukčić et al., 2020). In current study, despite differences in milk type and concentration, variations in total viable count were not statistically significant (Auldist et al., 1996). This suggests that factors other than milk type and concentration may have influenced the microbial population, such as environmental conditions, processing methods, or starter cultures used during cheese production (Mayo et al., 2021). However, it is remarkable that at the end of the storage period, some samples exhibited significantly higher total viable counts which can be attributed to presence of lactic acid bacteria that are responsible for flavor development in cheese (Tadjine et al., 2020). Similar findings were also reported by Barukčić et al. (2020). This can be attributed to various factors, including the proliferation of certain microbial species under specific storage conditions or the presence of spoilage microorganisms (Hamad, 2012). The presence of Enterobacteriaceae and yeasts and molds in cheese samples is of particular concern because these microorganisms may indicate contamination or spoilage (Laslo and György, 2018; Papaioannou et al., 2007). The absence of these microorganisms in the initial samples suggests good hygienic practices during cheese production (Prates et al., 2017). However, their emergence during storage highlights the importance of proper handling and storage conditions to prevent microbial proliferation. Interestingly, cheeses made from cow milk and higher cow milk blends exhibit lower levels of Enterobacteriaceae and yeasts and molds than goat milk-based cheeses. This may be attributed to inherent differences in the chemical and microbial composition of cow and goat milk (Collard and McCormick, 2021; Quigley et al., 2013; Turkmen, 2017). Low microbial counts in cow milk-based cheeses may also be associated with the presence of natural antiseptic like microbiota, favorable pH and water activity, higher lactose, amino acids and peptides (Łepecka et al., 2022; Barukčić et al., 2020). Differences in microbial growth between different samples highlight the complex interactions between milk composition and the microbial environment in cheese (Mayo et al., 2021). Although addition of up to 30% goat milk had no significant effect on microbial growth, further investigation into the threshold effects of milk adulteration on microbial quality is needed (Figure 3). The microbial quality analysis of cheese samples revealed intricate relationships between milk type, concentration, and microbial growth during storage. While cow milk-based cheeses demonstrated lower microbial counts compared to goat milk-based cheeses (Tadjine et al., 2020), the addition of goat milk at moderate concentrations had minimal effects on microbial quality.

Organoleptic characteristics of cottage cheese

The results of organoleptic analyses are displayed in Figure 4. Initially, CG1, CG2, and CG3 received significantly higher scores of 8.33, 8.32, and 8.32, respectively, for color and maintained this trend throughout the storage period. As the storage period increased, the scores rose and reached 8.98, 8.99, and 8.97, respectively, on day 15. Overall, CG1, CG2, and CG3 were deemed more acceptable to the judges compared to cheese made from blends of cow and goat milk or goat milk alone. Similarly, to color, the score for aroma increased from day 0 to day 15 as the cheese ripened. However, in terms of aroma, the difference among CG1, CG2, and CG3 was slightly significant but still higher than CG4, CG5, CG6, and CG7. On day 10, CG1 received the highest score of 8.93, followed by CG2 (8.9) and CG3 (8.89). Cheese made from CG4, CG5, CG6, and CG7 received significantly lower scores compared to the former three samples. Likewise, in terms of taste and texture, CG1, CG2, and CG3 received more favorable results compared to other samples. When the overall acceptability of the cottage cheese samples was analyzed, CG1, CG2, and CG3 emerged as the most acceptable cheese samples, indicating that adding 20% goat milk to 80% cow milk remained acceptable, similar to cheese made from cow milk alone.

The organoleptic properties of food products play an important role in determining its overall quality and consumer acceptance (Ahmad et al., 2023). Figures 4, 5 show the results of the organoleptic analyses where color is one of the primary attributes influencing consumer perception of food products (Huang and Lu, 2015). In this study, cottage cheese samples prepared from blends CG1, CG2, and CG3 obtained significantly higher scores for color than the other samples. This can be attributed to the higher fat content in cow milk than goat milk (Clark and García, 2017; Sadia et al., 2015), This trend remained consistent throughout the storage period (Figure 4A), indicating that the addition of goat milk positively affected the color characteristics of the cheese due to its smaller sized fat globules (Park et al., 2017) which gives shiny surface to the cheese by scattering light (Chakraborty et al., 2021). Aroma is another important aspect of sensory evaluation, which contributes significantly to the overall dining experience (Ouyang et al., 2018). The results indicated that the aroma scores of the cottage cheese samples increased as the cheese ripened during the storage period. However, CG1, CG2, and CG3 consistently received higher aroma scores than samples made from goat milk alone. This might be due to higher proportion of fatty acids such as caproic, capric and caprylic which give tangy aroma to the cheese made from goat milk alone or blends containing higher concentration of goat milk (Park et al., 2017). Moreover, with increase in storage duration different reactions take place including lipolysis and proteolysis which also results in production of such compounds that affect aroma of the cheese (Park, 2001; Jin and Park, 1995). Similarly, the results showed that CG1, CG2, and CG3 consistently received more favorable scores for taste and texture than the other samples. This means that the addition of goat milk in concentration below 30% resulted in cottage cheese with superior flavor and texture characteristics, possibly due to the higher proportion of fat in goat milk (Clark and García, 2017) that which gives it characteristic tangy taste and smooth texture (Park et al., 2017). Higher lactose content in cow milk could also the reason for higher sensory score (Collard and McCormick, 2021). Higher protein content can also the reason for good texture as they form firmer protein network (Chakraborty et al., 2021). Overall acceptability serves as a composite measure that reflects consumers’ overall perception of the product. The results show that addition of 20% goat milk to 80% cow milk maintains or improves the overall acceptability of cottage cheese (Figure 5), which is comparable to cheese made from cow milk alone that can be attributed to different composition of milk from two different species (Collard and McCormick, 2021; Roy et al., 2020; Clark and García, 2017). The results of this study show that adding goat milk to cottage cheese production can have a positive effect on its organoleptic properties, including color, aroma, flavor, texture, and overall acceptability.

Conclusions and Recommendations

Blending 20 to 30% goat milk with 70 to 80% cow milk produces nutritionally balanced cottage cheese that meets consumer preferences who are accustomed to cottage cheese made solely from cow milk. This blend maintains quality characteristics and organoleptic experience similar to cow milk cheese. However, generalizability of the results beyond the study country (Pakistan) is limited due to possible regional variations in organoleptic preferences. Further research with diverse populations is needed to validate global applicability of these findings. In addition, it is recommended to conduct further studies analyzing various minerals, such as calcium, present in cottage cheese.

Acknowledgements

This study has been carried out as the requirement for M.Sc. (Hons) degree of the first author. Artificial Intelligences (ChatGPT version 3.5) has been employed to correct grammatical mistakes and to enhance readability of the manuscript.

Novelty Statement

This study has not only assessed physicochemical and organoleptic characteristics of cottage cheese made from cow and goat milk in varying concentrations but also provide exact concentrations to prepare a cheese which utilizes both cow and goat milk with greater consumer acceptability. This is the novelty of this research.

Author’s Contribution

AI conceptualized, designed and carried out the study. IMQ and MSH supervised, carried out formal analysis and validated the results. AI and AA specified methodology, curated the data and prepared the first draft. HJ, FA, and SM assisted in resource allocation and investigation, proof read and formatted the manuscript for submission.

Conflict of interest

There is no conflict of interests among authors of this research paper.

References

Abd El-Gawad, M.A. and N.S. Ahmed. 2011. Cheese yield as affected by some parameters review. Acta Sci. Pol. Technol. Aliment., 10(2): 131-153.

Abdul-Hakim, B.N., N.J. Xuan and S.N.H. Oslan. 2023. A comprehensive review of bioactive compounds from lactic acid bacteria: Potential functions as functional food in dietetics and the food industry. Foods. 12(15): 2850. https://doi.org/10.3390/foods12152850

George F.W. and D.L. Ace. 1984. Extension goat handbook. Extension service United States department of agriculture, Washington D.C.

Ahmad, A., M.S. Hashmi, Y. Durrani, N.A. Khan, M.R., Khan, M.Z. Siddiqi, A. Riaz, M. Alam and W.U. Rahman. 2023. Synergy of 1-MCP and hypobaric treatments prevent fermented flavour and improve consumers acceptability of Shughri pear. J. Food Sci. Technol., 60(1): 200-210. https://doi.org/10.1007/s13197-022-05605-y

Akshit, F.N.U., T. Mao, R. Kaushik, V. Poswal and G.K. Deshwal. 2024. Global comprehensive review and meta-analysis of goat milk composition by location, publication year and lactation stage. J. Food Compost. Anal., 127: 0889-1575. https://doi.org/10.1016/j.jfca.2024.105973

Ali, A.M.M., A.S. Sant’Ana and S.C.B. Bavisetty. 2022. Sustainable preservation of cheese: Advanced technologies, physicochemical properties and sensory attributes. Trends Food Sci. Technol., 129: 306-326. https://doi.org/10.1016/j.tifs.2022.10.006

Ali, M.B., M.S. Murtaza, M. Shahbaz, A. Sameen, S. Rafique, R. Arshad, N. Raza, Z. Akbar, G. Kausar and A. Amjad. 2021. Functional, textural, physicochemical and sensorial evaluation of cottage cheese standardized with food grade coagulants. Food Sci. Technol., 42: 33420. https://doi.org/10.1590/fst.33420

Álvarez-Rosales, J.D., C. Ozuna, R. Salcedo-Hernández and G. Rodríguez-Hernández. 2019. Comparision of antioxidant activity of cow and goat milk during fermentation with lactobacillus acidophilus LA-5. Chapter. 2. In: Prebiotics and probiotics–Potential benefits in nutrition and health, IntechOpen.

AOAC, 2005. Official methods of analysis of the Association of Analytical Chemists (18th ed.). Gaithersburg, MD, USA.

Auldist, M.J., S. Coats, B.J. Sutherland, J.J. Mayes, G.H. McDowell and G.L. Rogers. 1996. Effects of somatic cell count and stage of lactation on raw milk composition and the yield and quality of Cheddar cheese. J. Dairy Res., 63(2): 269-280. https://doi.org/10.1017/S0022029900031769

Barukčić, I., M. Ščetar, I. Marasović, K. Lisak Jakopović, K. Galić and R. Božanić. 2020. Evaluation of quality parameters and shelf life of fresh cheese packed under modified atmosphere. J. Food Sci. Technol., 57: 2722-2731. https://doi.org/10.1007/s13197-020-04308-6

Batty, D., J.G. Waite-Cusic and L. Meunier-Goddik. 2019. Influence of cheese-making recipes on the composition and characteristics of Camembert-type cheese. J. Dairy Sci., 102(1): 164-176. https://doi.org/10.3168/jds.2018-14964

Birhanu, S., T. Tolemariam and T. Tolosa. 2013. Microbiological quality of Ayib, traditional Ethiopian cottage cheese, in Jimma area, South-West Ethiopia. Afr. J. Microbiol. Res., 7: 4169-75.

Bland, J.H., A.S. Grandison and C.C. Fagan. 2015. Effect of blending Jersey and Holstein-Friesian milk on Cheddar cheese processing, composition, and quality. J. Dairy Sci., 98(1): 1-8. https://doi.org/10.3168/jds.2014-8433

Boikhutso, J.M., 2010. Microbiological, physico-chemical and sensory quality aspects of dairy desserts manufactured from cottage cheese. PhD. thesis, University of Pretoria, South Africa.

Boukria, O., E.M. El-Hadrami, S. Boudalia, J. Safarov, F. Leriche and A. Aït-Kaddour. 2020. The effect of mixing milk of different species on chemical, physicochemical, and sensory features of cheeses: A review. Foods, 9(9): 1309. https://doi.org/10.3390/foods9091309

Ceballos, L.S., E.R. Morales, G. de la Torre Adarve, J.D. Castro, L.P. Martínez, and M.R.S Sampelayo. 2009. Composition of goat and cow milk produced under similar conditions and analyzed by identical methodology. J. Food Compost. Anal., 22(4): 322-329. https://doi.org/10.1016/j.jfca.2008.10.020

Chakraborty, P., U.S. Shivhare and S. Basu. 2021. Effect of milk composition on sensory attributes and instrumental properties of Indian cottage cheese (Chhana). NFS J., 23: 8-16. https://doi.org/10.1016/j.nfs.2021.02.002

Chen, Q., Q. Yin, Q. Xie, S.E. Evivie, X. Zhao, B. Li and G. Huo. 2022. Elucidating the physicochemical properties and surface composition of goat milk-based infant formula powders. Food Chem., 377: 131936. https://doi.org/10.1016/j.foodchem.2021.131936

Clark, S. and M.B.M. García. 2017. A 100-year review: Advances in goat milk research. J. Dairy Sci., 100(12): 10026-10044. https://doi.org/10.3168/jds.2017-13287

Clark, S. and J.W. Sherbon. 2000. Alphas1-casein, milk composition and coagulation properties of goat milk. Small Rumin. Res., 38(2): 123-134. https://doi.org/10.1016/S0921-4488(00)00154-1

Collard, K.M. and D.P. McCormick. 2021. A nutritional comparison of cow’s milk and alternative milk products. Acad. Pediatr., 21(6): 1067-1069. https://doi.org/10.1016/j.acap.2020.12.007

Darwish, A.A., M.I. El-Sayed and W.M. Salama. 2024. Physicochemical, texture, microstructure, and antioxidant characteristics of karish cheese made from ultrasonic-treated skimmed buffalo milk. Int. Dairy J., 152: 105878. https://doi.org/10.1016/j.idairyj.2023.105878

Derra, M., F. Bakkali, A. Amghar and H. Sahsah. 2018. Estimation of coagulation time in cheese manufacture using an ultrasonic pulse-echo technique. J. Food Eng., 216: 65-71. https://doi.org/10.1016/j.jfoodeng.2017.08.003

Dolby, R.M., F.H. Mcdowall and A.K.R. Mcdowell. 1937. 153 studies on the chemistry of Cheddar cheese making. VI. Factors affecting the relation between lactic acid and titratable acidity in Wheys. J. Dairy Res., 8(1): 86-91. https://doi.org/10.1017/S0022029900001953

dos Santos, W.M., A.C.G. Gomes, M.S. de Caldas Nobre, Á.M. de Souza Pereira, E.V. dos Santos Pereira, K.M.O. dos Santos, E.R. Florentino and F.C.A. Buriti. 2023. Goat milk as a natural source of bioactive compounds and strategies to enhance the amount of these beneficial components. Int. Dairy J., 137: 105515. https://doi.org/10.1016/j.idairyj.2022.105515

Dunshea, F.R., G.P. Walker, R. Williams and P.T. Doyle. 2019. Mineral and citrate concentrations in milk are affected by seasons, stage of lactation and management practices. Agriculture, 9(2): 25. https://doi.org/10.3390/agriculture9020025

Fekadu, B., K. Soryal, S. Zeng, D. Van Hekken, B. Bah and M. Villaquiran. 2005. Changes in goat milk composition during lactation and their effect on yield and quality of hard and semi-hard cheeses. Small Rumin. Res., 59(1): 55-63. https://doi.org/10.1016/j.smallrumres.2004.12.003

Filipczak-Fiutak, M., A. Pluta-Kubica, J. Domagała, I. Duda and W. Migdał. 2021. Nutritional value and organoleptic assessment of traditionally smoked cheeses made from goat, sheep and cow’s milk. PLoS One, 16(7): e0254431. https://doi.org/10.1371/journal.pone.0254431

Gallardo-Escamilla, F.J., A.L. Kelly and C.M. Delahunty. 2005. Sensory characteristics and related volatile flavor compound profiles of different types of whey. J. Dairy Sci., 88(8): 2689-2699. https://doi.org/10.3168/jds.S0022-0302(05)72947-7

Guetouache, M., B. Guessas and S. Medjekal. 2014. Composition and nutritional value of raw milk. J. Issues Biol. Sci. Pharm. Res., 2350: 1588.

Guinee, T.P., 2016. Protein in cheese and cheese products: Structure-function relationships. In: (eds. P. McSweeney and J. O’Mahony) advanced dairy chemistry. Springer, New York. https://doi.org/10.1007/978-1-4939-2800-2_14

Hamad, S.H., 2012. Factors affecting the growth of microorganisms in food. Progress in food preservation. Chapter. 20. p. 405-427. In: (eds. R. Bhat and G. Paliyath). Progress in food preservation, John Wiley and Sons, Inc., New Jersey. https://doi.org/10.1002/9781119962045.ch20

Hayat, R.S. and U. Meena. 2023. Essentiality of capacity building in the cottage industry of Pakistan: A synopsis of challenges and solutions. J. Sci. Technol. Innov. Policy, 9(1): 1-13. https://doi.org/10.11113/jostip.v9n1.125

Hettinga, K.A., 2019. Lactose in the dairy production chain. Chapter. 6. p. 231-266. In: (eds. M. Paques and C. Lindner). Lactose: Evolutionary role, health effects, and applications Academic Press. Wageningen, Elsevier Inc. https://doi.org/10.1016/B978-0-12-811720-0.00006-4

Ho, T.M., T. Howes and B.R. Bhandari. 2016. Methods to extend the shelf‐life of cottage cheese. A review. Int. J. Dairy Technol., 69(3): 313-327. https://doi.org/10.1111/1471-0307.12309

Huang, L. and J. Lu. 2015. Eat with your eyes: Package color influences the expectation of food taste and healthiness moderated by external eating. Mark. Manag., 25(2): 71-87.

ISO, 2004. Microbiology of food and animal feeding stuffs: horizontal methods for the detection and enumeration of Enterobacteriaceae: Part 2: Colony-count method. ISO. Geneva, Switzerland: International organisation for standardisation.

ISO, 2008. Microbiology of food and animal feeding stuffs – Horizontal method for the enumeration of yeasts and molds - Part 1: Colony count technique in products with water activity greater than 0.95. ISO 21527-1. Geneva, Switzerland: International standardisation organisation.

ISO, 2013. ISO/TS Standard No. 4833-1: Microbiology of the food chain – Horizontal method for the enumeration of microorganisms – Part 1: Colony count at 30 °C by the pour plate technique. Geneva, Switzerland: International Organisation for Standardisation.

Mahmood, A. and S. Usman. 2010. A comparative study on the physicochemical parameters of milk samples collected from buffalo, cow, goat and sheep of Gujrat, Pakistan. Pak. J. Nutr., 9(12): 1192-1197. https://doi.org/10.3923/pjn.2010.1192.1197

Jin, Y.K. and Y.W. Park. 1995. Effects of aging time and temperature on proteolysis of commercial goat milk cheeses produced in the United States. J. Dairy Sci., 78(12): 2598-2608. https://doi.org/10.3168/jds.S0022-0302(95)76888-6

Johnson, M.E., 2017. A 100-year review: Cheese production and quality. J. Dairy Sci., 100(12): 9952-9965. https://doi.org/10.3168/jds.2017-12979

Kindstedt, P.S., 2014. The basics of cheesemaking. Chapter.2. p. 17-38. In: eds. C.W. Donnelly and Cheese and microbes ASM Press. Washington, D.C. https://doi.org/10.1128/9781555818593.ch2

Kodrik, L., L. Wágner, K. Imre, K.F. Polyak, F. Besenyei and F. Husvéth. 2011. The effect of highway traffic on heavy metal content of cow milk and cheese. Hung. J. Ind. Chem., 39(1): 15-19.

Laslo, É. and É. György. 2018. Evaluation of the microbiological quality of some dairy products. Acta Univ. Sapientiae Alimen., 11(1): 27-44. https://doi.org/10.2478/ausal-2018-0002

Łepecka, A., A. Okoń, P. Szymański, D. Zielińska, K. Kajak-Siemaszko, D. Jaworska, K. Neffe-Skocińska, B. Sionek, M. Trząskowska, D. Kołożyn-Krajewska and Z.J. Dolatowski. 2022. The use of unique, environmental lactic Acid Bacteria strains in the traditional production of organic cheeses from unpasteurized cow’s milk. Molecules, 27(3): 1097. https://doi.org/10.3390/molecules27031097

Linares, D.M., C. Gómez, R.P. Ross and C. Stanton. 2017. Lactic acid bacteria and bifidobacteria with potential to design natural biofunctional health-promoting dairy foods. Front. Microbiol., 8: 248410. https://doi.org/10.3389/fmicb.2017.00846

Manuelian, C.L., S. Currò, M. Penasa, M. Cassandro and M. De Marchi. 2017. Characterization of major and trace minerals, fatty acid composition, and cholesterol content of protected designation of origin cheeses. J. Dairy Sci., 100(5): 3384-3395. https://doi.org/10.3168/jds.2016-12059

Martin, C., R. Schoumacker, D. Bourjade, T. Thomas-Danguin, E. Guichard, J.L. Le Quéré and H. Laboure. 2016. Sensory properties linked to fat content and tasting temperature in cottage cheese. Dairy Sci. Technol., 96: 735-746. https://doi.org/10.1007/s13594-016-0301-6

Mayo, B., J. Rodríguez, L. Vázquez and A.B. Flórez. 2021. Microbial interactions within the cheese ecosystem and their application to improve quality and safety. Foods, 10(3): 602. https://doi.org/10.3390/foods10030602

Moatsou, G. and Y.W. Park. 2017. Goat milk products: Types of products, manufacturing technology, chemical composition, and marketing. Chapter. 2.3. p. 84-150. In: (eds. Y.W. Park, G.F. Haenlein and W.L. Wendorff). Handbook of Milk of non‐bovine Mammals, John Wiley and Sons, Inc., New Jersey. https://doi.org/10.1002/9781119110316.ch2.3

Noël, L., M. Carl, C. Vastel and T. Guérin. 2008. Determination of sodium, potassium, calcium and magnesium content in milk products by flame atomic absorption spectrometry (FAAS): A joint ISO/IDF collaborative study. Int. Dairy J., 18(9): 899-904. https://doi.org/10.1016/j.idairyj.2008.01.003

Ouyang, Y., C. Behnke, B. Almanza and R. Ghiselli. 2018. The influence of food aromas on restaurant consumer emotions, perceptions, and purchases. J. Hosp. Mark. Manag., 27(4): 405-423. https://doi.org/10.1080/19368623.2017.1374225

Papaioannou, G., I. Chouliara, A.E. Karatapanis, M.G. Kontominas and I.N. Savvaidis. 2007. Shelf-life of a Greek whey cheese under modified atmosphere packaging. Int. Dairy J., 17(4): 358-364. https://doi.org/10.1016/j.idairyj.2006.04.001

Park, Y.W., 1994. Hypo-allergenic and therapeutic significance of goat milk. Small Rumin. Res., 14(2): 151-159. https://doi.org/10.1016/0921-4488(94)90105-8

Park, Y.W., 2001. Proteolysis and lipolysis of goat milk cheese. J. Dairy Sci., 84: E84-E92. https://doi.org/10.3168/jds.S0022-0302(01)70202-0

Park, Y.W., G.F.W. Haenlein and Y.H. Hui. 2007. Handbook of food products manufacturing. Goat milk, its products and nutrition. John Wiley and Sons, Inc., New Jersey. https://doi.org/10.1002/9780470113554.ch69

Park, Y.W., C. Jeanjulien and A. Siddique. 2017. Factors affecting sensory quality of goat milk cheeses: A review. J. Adv. Dairy Res., 5(185): 2. https://doi.org/10.4172/2329-888X.1000185

Possas, A., O.M. Bonilla-Luque and A. Valero. 2021. From cheese-making to consumption: Exploring the microbial safety of cheeses through predictive microbiology models. Foods, 10(2): 355. https://doi.org/10.3390/foods10020355

Prazeres, A.R., F. Carvalho and J. Rivas. 2012. Cheese whey management: A review. J. Environ. Manage., 110: 48-68. https://doi.org/10.1016/j.jenvman.2012.05.018

Prates, D.D.F., S.R. Würfel, J.C. Goldbeck, A.S.D. Lima, G.V. Lopes and W.P.D. Silva. 2017. Microbiological quality and safety assessment in the production of moderate and high humidity cheeses. Ciênc. Rural., 47: e20170363. https://doi.org/10.1590/0103-8478cr20170363

Puledda, A., G. Gaspa, M.G. Manca, J. Serdino, P.P. Urgeghe, C. Dimauro, R. Negrini and N.P.P. Macciotta. 2017. Estimates of heritability and genetic correlations for milk coagulation properties and individual laboratory cheese yield in Sarda ewes. Animal, 11(6): 920-928. https://doi.org/10.1017/S1751731116002147

Quigley, L., O. O’Sullivan, C. Stanton, T.P. Beresford, R.P. Ross, G.F. Fitzgerald and P.D. Cotter. 2013. The complex microbiota of raw milk. FEMS Microbiol. Rev., 37(5): 664-698. https://doi.org/10.1111/1574-6976.12030

Rasheed, S., I.M. Qazi, I. Ahmed, I., Y. Durrani and Z. Azmat. 2016. Comparative study of cottage cheese prepared from various sources of milk. Proc. Pakistan Acad. Sci., 53(4): 269-282.

Razzaq, S., 2003. Preparation of cottage cheese using Sodom apple (Calotropis procerra) latex as a plant rennet. M. Sc. (Hons.) thesis, University of Arid Agriculture, Rawalpindi.

Roy, D., A. Ye, P.J. Moughan and H. Singh. 2020. Composition, structure, and digestive dynamics of milk from different species. A review. Front. Nutr., 7: 577759. https://doi.org/10.3389/fnut.2020.577759

Sadia, R., Q.I. Mabood, A. Ishfaq, D. Yasser and A. Zarmeena. 2015. Comparative study of cottage cheese prepared from various sources of milk. Proc. Pak. Acad. Sci., 53: 2518-4261.

Sharmila, S., S. Preetha, M. Dinesh, B. Shrivatasan, S. Sadik, R. Kamalambigeswari, E. Kowsalya and L.J. Rebecca. 2018. A study on quality of curd produced from different types of milk. World J. Pharm. Res., 7(8): 693-700.

Setyawardani, T., J. Sumarmono, H. Dwiyanti and N.D. Arkan. 2023. Yield, composition, texture, and sensory characteristics of cottage cheese produced with the incorporation of different herb extracts. Anim. Prod., 25(2): 109-117. https://doi.org/10.20884/1.jap.2023.25.2.197

Štefániková, J., V. Ducková, M. Miškeje, M. Kačániová and M. Čanigová. 2020. The impact of different factors on the quality and volatile organic compounds profile in “Bryndza” cheese. Foods, 9(9): 1195. https://doi.org/10.3390/foods9091195

Stocco, G., M. Pazzola, M.L. Dettori, P. Paschino, G. Bittante and G.M. Vacca. 2018. Effect of composition on coagulation, curd firming, and syneresis of goat milk. J. Dairy Sci., 101(11): 9693-9702.

Tadjine, D., S. Boudalia, A. Bousbia, Y. Gueroui, G. Symeon, L. Mebirouk Boudechiche, A. Tadjine and M. Chemmam. 2020. Milk heat treatment affects microbial characteristics of cows and goats Jben traditional fresh cheeses. Food Sci. Technol., 41: 136-143. https://doi.org/10.1590/fst.00620

Troch, T., É. Lefébure, V. Baeten, F. Colinet, N. Gengler and M. Sindic. 2017. Cow milk coagulation: process description, variation factors and evaluation methodologies. A review. Biotechnol. Agron. Soc. Environ., 21(4): 276-287. https://doi.org/10.25518/1780-4507.13692

Turkmen, N., 2017. The nutritional value and health benefits of goat milk components. Chapter. 35. p. 441-449. In: (eds. A.M. Parker and R.R. Watson. Nutrients in dairy and their implications on health and disease. Academic Press. Elsevier Inc. https://doi.org/10.1016/B978-0-12-809762-5.00035-8

Tyl, C. and G.D. Sadler. 2017. pH and titratable acidity. Food Anal., pp. 389-406. https://doi.org/10.1007/978-3-319-45776-5_22

Vacca, G.M., G. Stocco, M.L. Dettori, G. Bittante and M. Pazzola. 2020. Goat cheese yield and recovery of fat, protein, and total solids in curd are affected by milk coagulation properties. J. Dairy Sci., 103(2): 1352-1365. https://doi.org/10.3168/jds.2019-16424

Van Boekel, M.A.J.S., 1994. Transfer of milk components into cheese: Scientific considerations. In: Proc. IDF Seminar, Cork, Ierland 1993: Factors affecting yield of cheese and systems for its control. IDF Special Issue no 9402: 19-28.

Yasar, K. and N. Guzeler. 2011. Effects of coagulant type on the physicochemical and organoleptic properties of Kashar cheese. Int. J. Dairy Technol., 64(3): 372-379. https://doi.org/10.1111/j.1471-0307.2011.00679.x

To share on other social networks, click on any share button. What are these?